Refuse leachate treatment method

A technology for landfill leachate and a treatment method, applied in the field of landfill leachate treatment, can solve the problems of inability to flexibly adapt to changes in landfill leachate water quality, high treatment cost, low treatment efficiency, etc. The effect of high removal efficiency and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

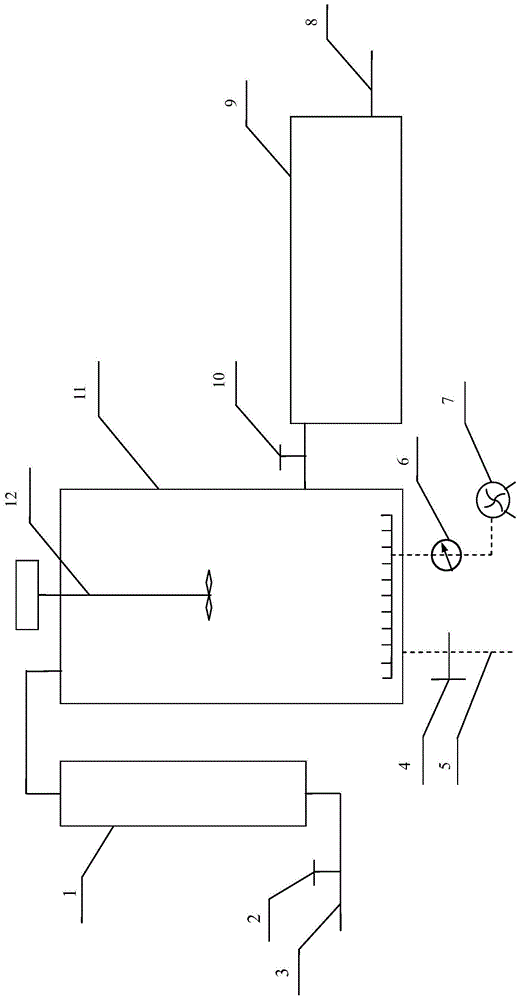

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of landfill leachate processing method is characterized in that, comprises the following steps:

[0030] The first step: open the water inlet valve 2, the landfill leachate flows through the adsorption column 1 filled with natural zeolite and boron mud filler, and enters the sequencing batch reactor 11 equipped with a mechanical stirring device 12, and the water inlet flow rate is controlled to 4.8L / min, the delayed water intake time is 0.5h;

[0031] Step 2: After the water inlet is completed, close the water inlet valve 2 of the adsorption column, turn on the air compressor 7, and carry out blast aeration to the landfill leachate in the reactor, the aeration rate is 2.3L / min, and the aeration time is 2.5 hours;

[0032] The third step: turn off the air compressor 7, turn on the mechanical stirring device 12, and perform anoxic stirring on the landfill leachate in the reactor, the stirring rate is 30r / min, and the stirring time is controlled at 1...

Embodiment 2

[0040] Embodiment 2: a kind of landfill leachate processing method adopts the sequence batch reactor 12 that stirring motor 3 and propeller 4 are housed, it is characterized in that, comprises the following steps:

[0041] The first step: open the water inlet valve 2, the landfill leachate flows through the adsorption column 1 filled with boron mud, and enters the sequencing batch reactor 11 equipped with a mechanical stirring device 12, the water inlet flow rate is controlled at 3.4L / min, and the time delay Water intake time is 1.0h;

[0042] Step 2: After the water inlet is completed, close the water inlet valve 2 of the adsorption column, turn on the air compressor 7, and carry out blast aeration to the landfill leachate in the reactor, the aeration rate is 2.4L / min, and the aeration time is 2.0h;

[0043] The third step: turn off the air compressor 7, turn on the mechanical stirring device 12, and perform anoxic stirring on the landfill leachate in the reactor, the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com