A kind of sealing agent for gas drainage and its preparation method

A gas drainage and sealing agent technology, which is applied in the industrial and mining field, can solve the problems of difficulty in fully exerting the active effect and poor red mud utilization rate, and achieve the effects of fine fineness, good fluidity, and good plugging and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Experimental temperature: normal temperature (21~25℃)

[0038] Experimental equipment: WDW-300E electronic universal testing machine.

[0039]According to the mass ratio of the formula: red mud 45%, finely ground steel slag powder 5%, calcium aluminate powder 20%, desulfurization gypsum powder 4%, calcium carbide slag 5%, fly ash 20%, regulator 0.4%, pipeline transportation improvement After mixing with water according to the water-cement ratio of 0.6, it was put into the testing machine for experiment. The regulator is a mixture of aluminum-oxygen clinker and lithium chloride in a mass ratio of 4:1, and the pipeline conveying modifier is bentonite, calcium lignosulfonate and naphthalenesulfonate formaldehyde condensate water reducing agent in a ratio of 5:1:0.5 Proportional mix.

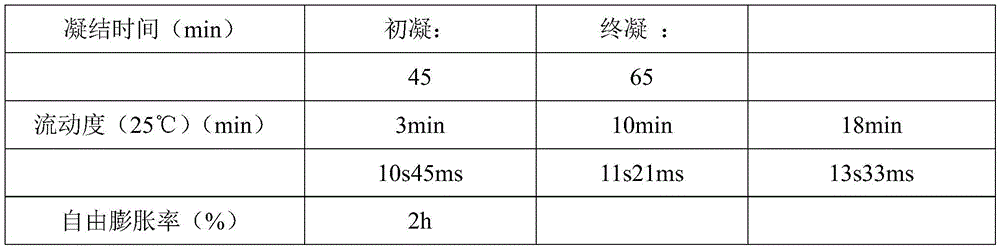

[0040] The experimental results are shown in Table 1.

[0041] Table 1 Technical index of sealing agent for coal seam gas drainage

[0042] Coagulation time (min) Initial setti...

Embodiment 2

[0044] Experimental temperature: normal temperature (21-25℃)

[0045] Experimental equipment: WDW-300E electronic universal testing machine.

[0046] According to the mass ratio of the formula: red mud 25%, finely ground steel slag powder 10%, calcium aluminate powder 20%, desulfurized gypsum powder 4%, calcium carbide slag 9%, fly ash 30%, regulator 0.8%, pipeline transportation improvement After mixing with water according to the water-cement ratio of 0.55, it was put into the testing machine for experiment. Wherein, the regulator is the mixture of aluminum-oxygen clinker and lithium chloride by mass ratio of 3:1, and the pipeline conveying modifier is bentonite, calcium lignosulfonate and naphthalenesulfonate formaldehyde condensate water reducing agent with 5:1: 1 ratio mix.

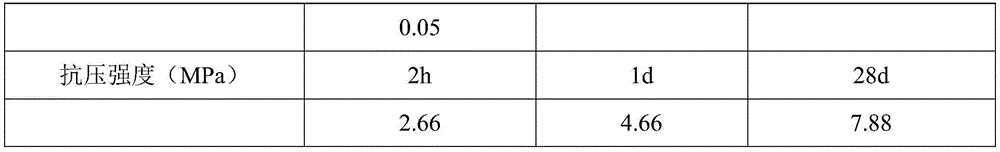

[0047] The experimental results are shown in Table 2.

[0048] Table 2 Technical index of sealing agent for coal seam gas drainage

[0049]

[0050]

Embodiment 3

[0052] Experimental temperature: normal temperature (21-25℃)

[0053] Experimental equipment: WDW-300E electronic universal testing machine.

[0054] According to the mass ratio of the formula: red mud 30%, finely ground steel slag powder 9%, calcium aluminate powder 25%, desulfurized gypsum powder 2%, calcium carbide slag 8%, fly ash 25%, regulator 0.4%, pipeline transportation improvement After mixing with water according to the water-cement ratio of 0.50, it was put into the testing machine for experiment. Among them, the regulator is a mixture of aluminum-oxygen clinker and lithium chloride in a mass ratio of 4:1, and the pipeline transportation modifier is bentonite, polyacrylamide, calcium lignosulfonate and naphthalenesulfonate formaldehyde condensate water reducing agent to Mix in a ratio of 4:0.1:1:0.5.

[0055] The experimental results are shown in Table 3:

[0056] Table 3 Technical index of sealing agent for coal seam gas drainage

[0057] Coagulation ...

PUM

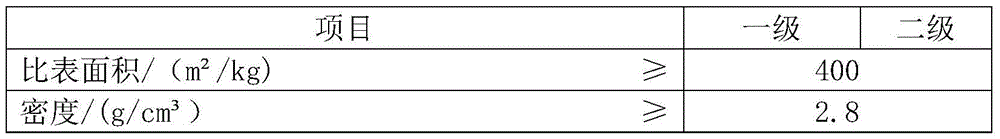

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com