Polyester production device

A production device and polyester technology, applied in the field of polymer production devices, can solve the problems of changes in the crystallinity and crystallization speed of polyester products, difficult diffusion and removal of small molecules, and difficulty in growing molecular chains. The effect of automatic granulation and dicing, accelerated removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

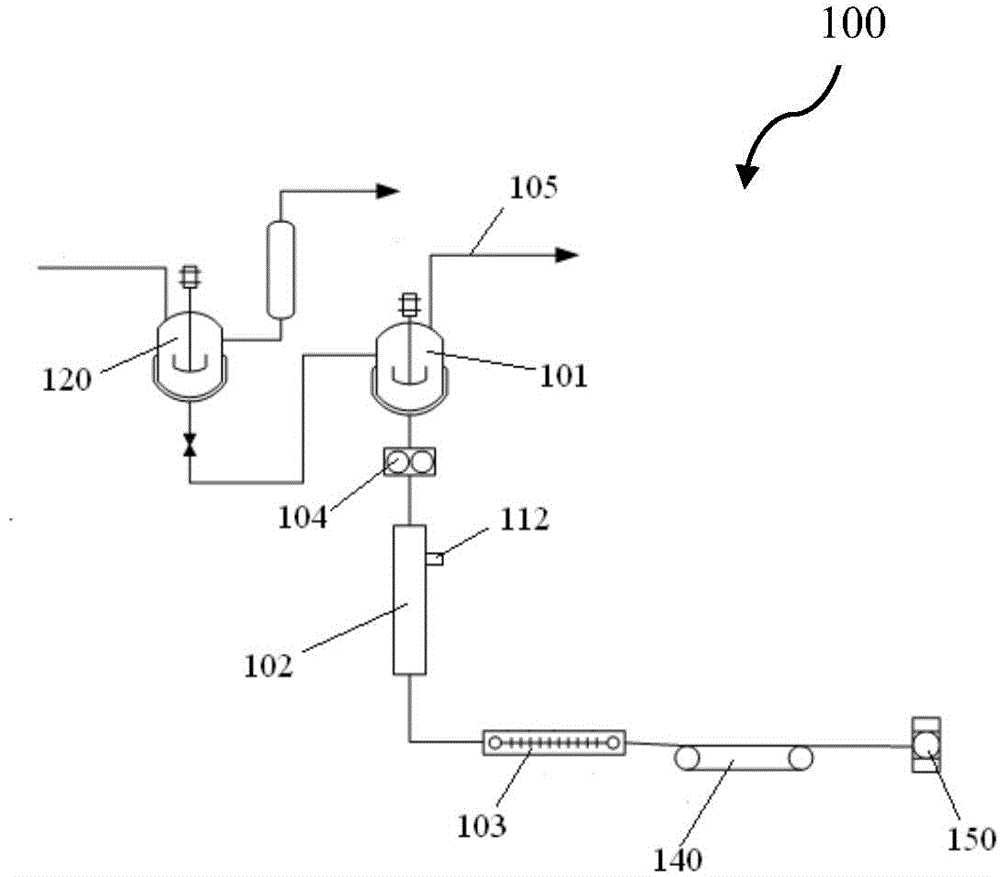

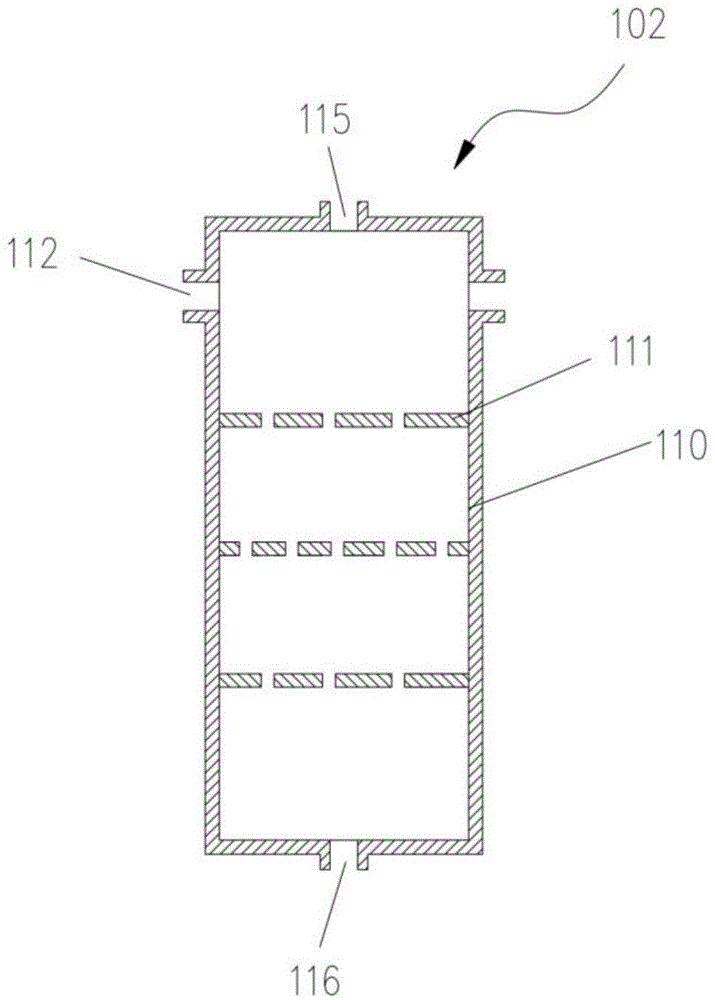

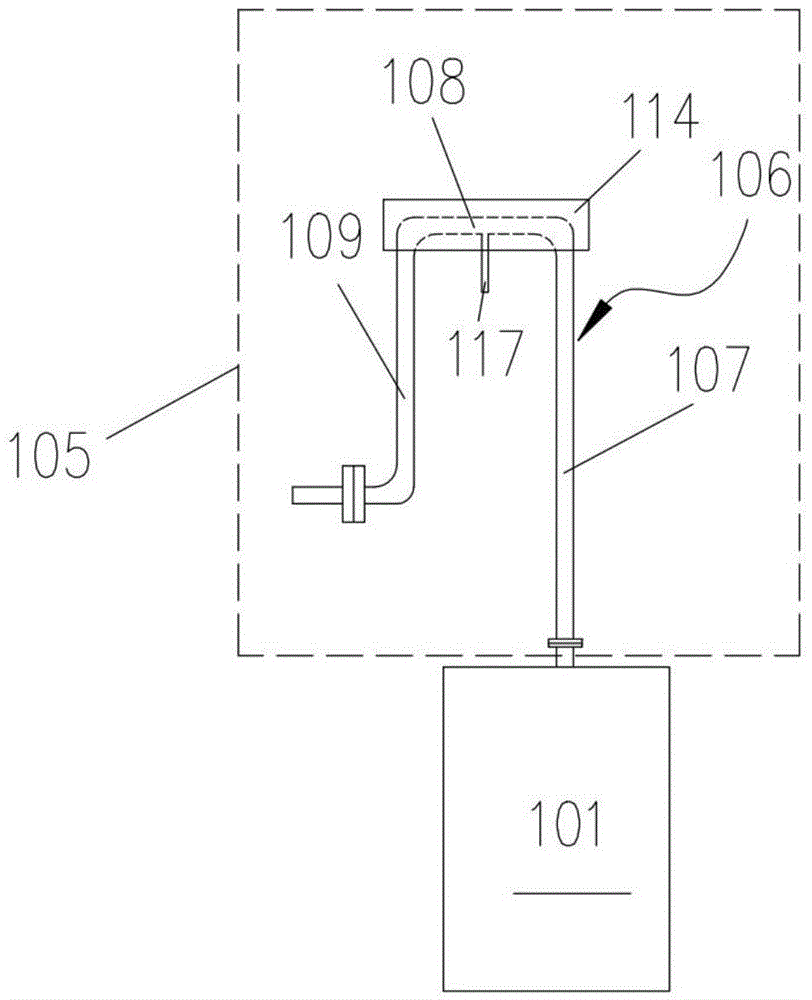

[0026] figure 1 A polyester production plant 100 according to the invention is schematically shown. The polyester production device 100 includes a polycondensation reactor 101 , a vacuum static reactor 102 is arranged downstream of the polycondensation reactor 101 , and an extrusion device 103 is arranged downstream of the vacuum static reactor 102 . The vacuum static reactor 102 is used to greatly increase the volatilization of small molecular substances in the material, so that the molecular chain of the polyester can be further extended. The structure of the vacuum static reactor 102 will be further described below. It should be understood that the polyester production device 100 may further include an esterification reactor 120 disposed upstream of the polycondensation reactor 101, so that acid and alcohol may be used as raw materials to synthesize polyester. Both the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com