Nano-copper antibacterial plastic masterbatch and preparation method thereof

A technology of antibacterial plastics and nano-copper, which is applied in the field of nano-copper antibacterial plastic masterbatch and its preparation, can solve the problems of high price of silver-based antibacterial agents, failure to meet antibacterial requirements, and reduced commercial value, etc., to achieve complete and effective antibacterial, mildew-proof, Easy to distribute evenly, good antibacterial and antifungal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

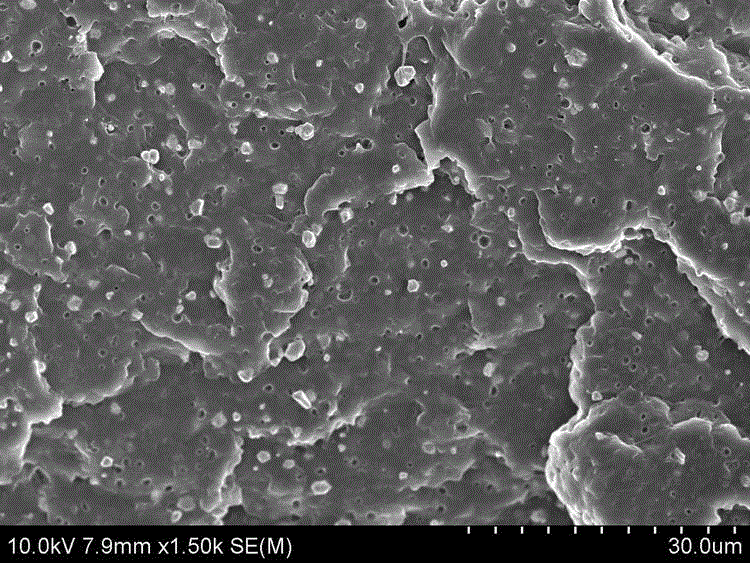

[0023] Embodiment 1: an antibacterial plastic master batch, the weight parts of each component are as follows: 40 parts of polypropylene resin, 20 parts of liquid paraffin, 10 parts of antioxidant, 30 parts of nano-copper antibacterial agent, when preparing, first pre-treating raw materials , process the polypropylene resin into a plastic powder with a particle size between 1 μm and 20 μm, and dry the nano-copper antibacterial powder, and then blend the components according to conventional methods in the art, and use a twin-screw extruder to carry out For processing, the parameters of the twin-screw extruder are set to: 90°C in the first zone, 120°C in the second zone, 130°C in the third zone, 150°C in the fourth zone, 160°C in the fifth zone, 180°C in the sixth zone, 190°C in the seventh zone, and 190°C in the eighth zone. , 200 ℃ in nine zones, the main engine speed is 100 rpm, the feeding speed is 10 rpm, dicing, and low temperature drying. The SEM image of the antibacteria...

Embodiment 2

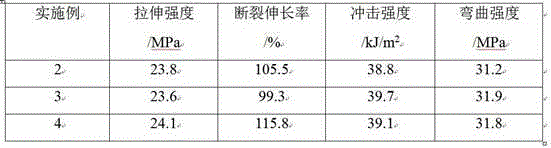

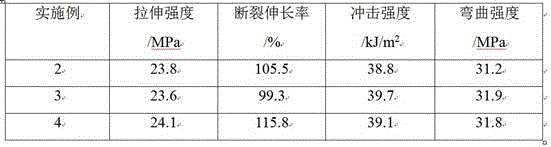

[0024] Embodiment 2: an antibacterial plastic masterbatch, the weight parts of each component are as follows: 80 parts of polypropylene resin, 1 part of liquid paraffin, 3 parts of antioxidant, 16 parts of nano-copper antibacterial agent, when preparing, first pretreating raw materials , process the polypropylene resin into a plastic powder with a particle size between 1 μm and 20 μm, and dry the nano-copper antibacterial powder, and then blend the components according to conventional methods in the art, and use a twin-screw extruder to carry out For processing, the parameters of the twin-screw extruder are set to: 120°C in the first zone, 130°C in the second zone, 140°C in the third zone, 150°C in the fourth zone, 160°C in the fifth zone, 190°C in the sixth zone, 190°C in the seventh zone, and 200°C in the eighth zone. , nine zones 200 ℃, main engine speed 150 rpm, feeding speed 15 rpm, dicing, low temperature drying. The antibacterial plastic masterbatch obtained in this exa...

Embodiment 3

[0025] Embodiment 3: an antibacterial plastic masterbatch, the weight parts of each component are as follows: 85 parts of polypropylene resin, 3 parts of liquid paraffin, 1 part of antioxidant, 11 parts of nano-copper antibacterial agent, when preparing, first pretreating raw materials , process the polypropylene resin into a plastic powder with a particle size between 1 μm and 20 μm, and dry the nano-copper antibacterial powder, and then blend the components according to conventional methods in the art, and use a twin-screw extruder to carry out For processing, the parameters of the twin-screw extruder are set to: 130°C in the first zone, 150°C in the second zone, 170°C in the third zone, 180°C in the fourth zone, 180°C in the fifth zone, 185°C in the sixth zone, 185°C in the seventh zone, and 195°C in the eighth zone. Nine zones 195°C, main engine speed 200 rpm, feeding speed 20 rpm, dicing, low temperature drying. The antibacterial plastic masterbatch obtained in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com