Preparation method of titanium alloy and use of titanium alloy

A technology of titanium alloy and titanium alloy plate, applied in the direction of electrolysis, electroforming, etc., can solve the problems of poor hardness and rigidity, and achieve the effect of high cost performance, high hardness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

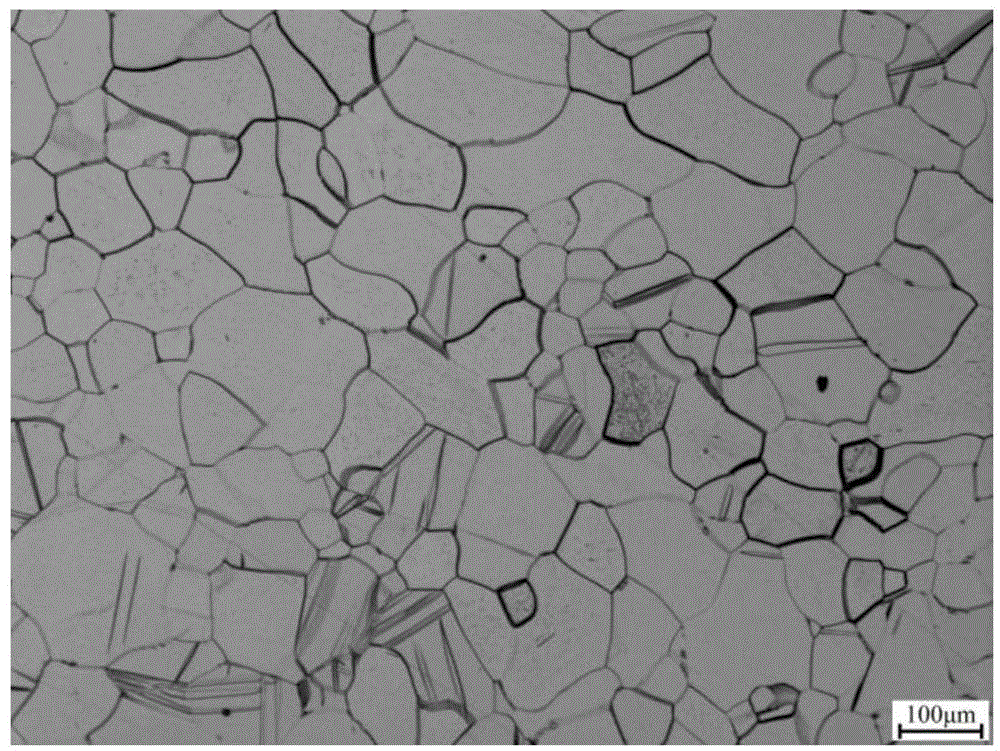

Embodiment 1

[0030] Will Y 2 o 3 Add it into sponge titanium and mix it, press it into an electrode, and then use argon arc welding to connect it into an electrode rod, melt it in a vacuum melting furnace and cast it into a titanium ingot; the mass ratio of Y element to titanium sponge is 0.8:1, and the smelting The temperature value is higher than the highest melting point value of the substance used above. The vacuum degree in the vacuum melting furnace is 1.0*10 -1 Pa, titanium ingots were smelted three times in a vacuum melting furnace. The titanium ingot is subjected to rough blank forging, the titanium ingot is placed in a heating furnace, and after being kept at a temperature of 900° C. for 1 hour, it is subjected to three pier and three pull forging treatments to obtain a roughly treated titanium alloy slab. The temperature in the vacuum melting furnace is higher than the melting point of the selected substance, and the current and other parameter values are determined accordi...

Embodiment 2

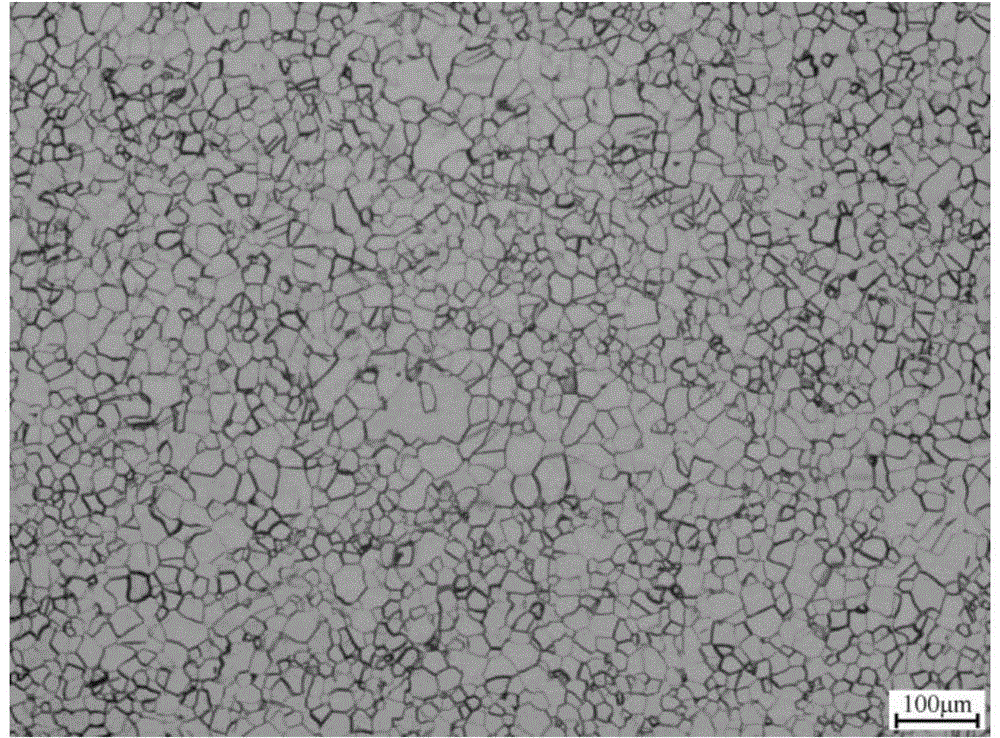

[0033] Will Y 2 o 3 Add it into sponge titanium and mix it, press it into an electrode rod, and then use argon arc welding to connect it into an electrode rod, and melt it into an ingot in a vacuum melting furnace; the mass ratio of Y element to sponge titanium is 2.6:1, and the smelting The temperature value is higher than the highest melting point value of the substance used above. The vacuum degree in the vacuum melting furnace is 0.8*10 -1 Pa. The ingots are melted three times in a vacuum melting furnace. The ingot was subjected to rough billet forging, and the ingot was placed in a heating furnace, kept at a temperature of 900° C. for 1 hour, and then subjected to three-piercing and three-drawing forging treatment to obtain a titanium alloy slab. The temperature in the vacuum melting furnace is higher than the melting point of the selected substance, and the current and other parameter values are determined according to the selected vacuum melting furnace.

[0034]...

Embodiment 3

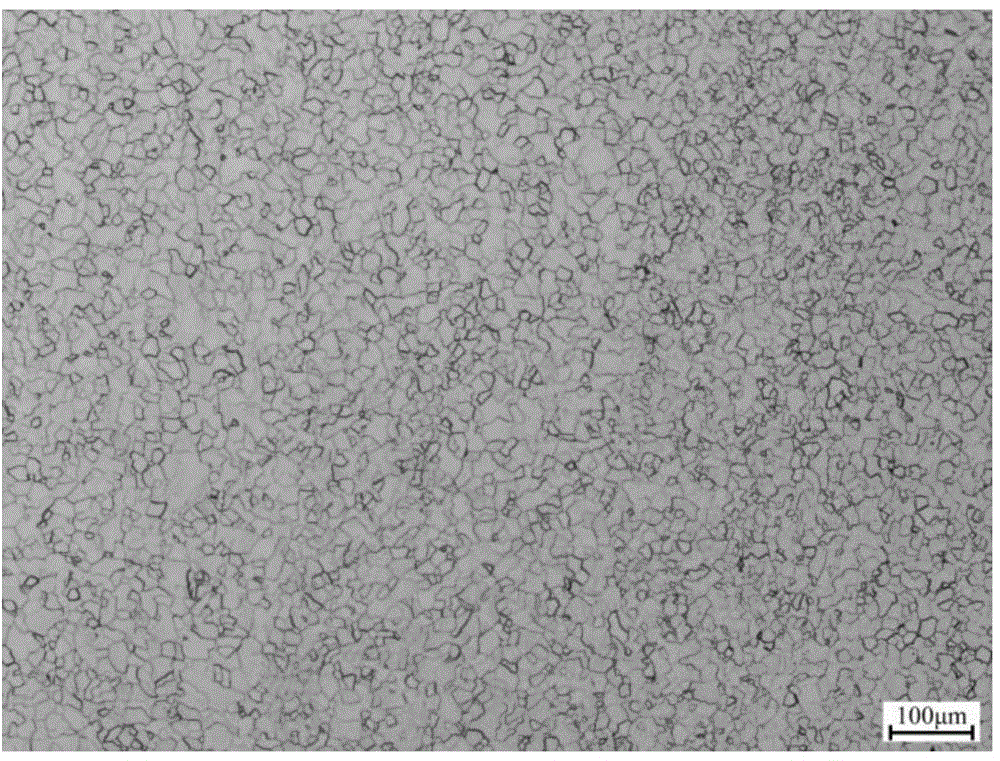

[0041] Will Y 2 o 3 Add it into sponge titanium and mix it, press it into an electrode pole, and then use argon arc welding to connect it into an electrode rod, melt and cast it into a titanium ingot in a vacuum melting furnace; the mass ratio of Y element to titanium sponge is 3:1, The melting temperature value is the highest melting point value of the selected substance. The vacuum degree in the vacuum melting furnace is 1.0*10 -1 Pa. The ingots are melted three times in a vacuum melting furnace. The ingot was subjected to rough billet forging, the ingot was placed in a heating furnace, kept at a temperature of 950° C. for 1 hour, and then subjected to three-piercing and three-drawing forging to obtain a rough-treated titanium alloy slab. The temperature in the vacuum melting furnace is higher than the melting point of the selected substance, and the current and other parameter values are determined according to the selected vacuum melting furnace.

[0042] Titanium all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com