High-temperature titanium alloy

A technology of high-temperature titanium alloys and alloys, which is applied in the fields of high-temperature titanium alloy materials, high-temperature titanium alloys, and high-temperature structural parts, can solve the difficulty of increasing the uniformity control of ingot composition, and has not yet seen practical application reports, W element addition Difficulties and other problems, to achieve the effect of improving high temperature and high stress durability, improving oxidation resistance, and ensuring room temperature plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

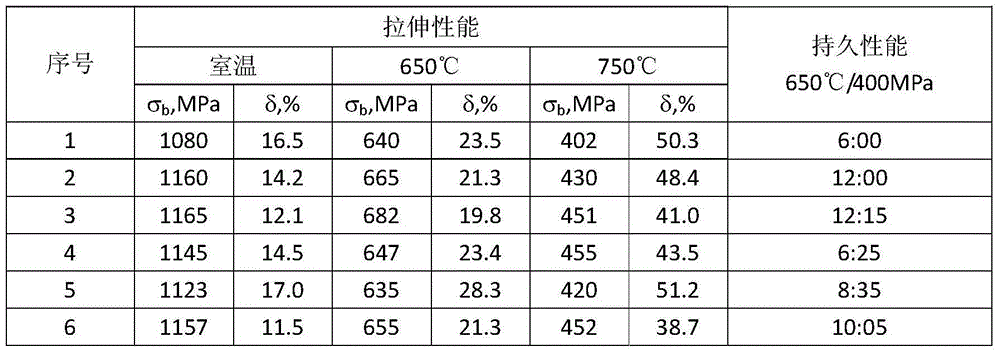

[0023] Using a vacuum consumable arc melting furnace, a 20kg ingot was prepared according to the ingredients given in Table 1, with an oxygen content of 0.08%, which was forged and rolled to obtain The rods, the tensile and durability properties of the rods were tested after heat treatment, as shown in Table 2, it can be seen that high Al equivalent has a significant effect on improving tensile strength; high Mo content is beneficial to improving high temperature durability; high Nb content is beneficial to improving The plasticity at room temperature is beneficial; increasing the C content is beneficial to improving the durability, but reducing the elongation at room temperature.

[0024] Table 1 Design ingredients of 20kg ingot

[0025] serial number

Ingredients

Al equivalent, %

1

Ti‐5.5Al‐3Sn‐4Zr‐1Hf‐3.5Mo‐3.5Nb‐0.4Si‐0.06C

7.97

2

Ti‐6.8Al‐2Sn‐4Zr‐0.04Hf‐2.5Mo‐2.5Nb‐0.4Si‐0.06C

8.94

3

Ti‐7.5Al‐2Sn‐4Zr‐0.04Hf‐1.5Mo‐2...

Embodiment 7~10

[0029] Using a non-consumable vacuum furnace, button ingots with 4 components were smelted, and the batching weight was 50g. Test pieces of 3×10×2mm were prepared respectively, and the oxidation weight gain after heat exposure at 650°C / 100h was compared, see Table 3 , with the increase of Hf content, the weight gain of oxidation decreases, and the addition of 0.03% Hf has shown the effect of improving the antioxidant performance.

[0030] Table 3 Effect of Hf content on the oxidation resistance of alloys

[0031] serial number

[0032] 10

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com