Preparation Technology of Porous Copper-based Shape Memory Alloy by Equal Angle Extrusion

A technology of equal-diameter angular extrusion and memory alloy, which is applied in the field of preparation of new functional materials and porous copper-based shape memory alloy materials, can solve the problems of poor environmental protection effect, complicated preparation method, long preparation line, etc., and achieve enhanced green environmental protection Effect, short process line, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

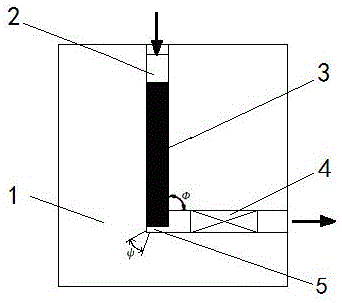

[0015] A preparation process of porous copper-based shape memory alloy by equal-diameter angular extrusion method. The proportioned and mixed Cu-Zn-Al metal powder is pressed through a simple pressing die, and then sintered into a preform, and then the sintered preform is Put it into the concave die 1 of the equal-diameter angular extrusion die. Under the action of the punch 2, the blank 3 passes through the corner area 5 and the spiral channel area 4 successively, resulting in two large plastic deformations. Squeeze forming, the billet 3 can produce accumulated plastic deformation, so that the powder is consolidated, broken, dense, and grains are broken, sub-grains are generated, a large number of nuclei are formed, and grains are refined; then multi-pass equal-diameter angular extrusion The porous copper-based shape memory alloy material with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com