Preparation method of organosilicon multiple copolymer fabric softener

A multi-component copolymer and fabric softener technology, which is applied in the field of polymer synthesis, can solve the problems that the ternary block silicone oil softener cannot have both softness and durability, and the fabric is easy to yellow, so as to achieve a rich and full hand feeling, good Soft effect, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

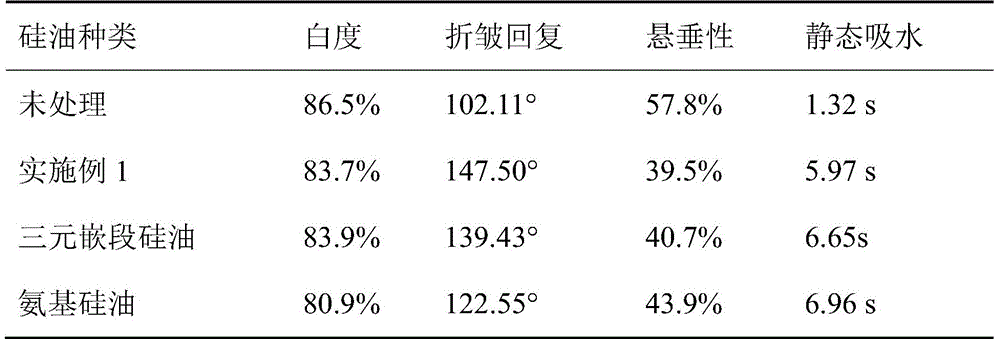

Examples

preparation example Construction

[0024] The preparation method of organosilicon multi-polymer copolymer fabric softener of the present invention specifically comprises the following steps:

[0025] Step 1: Add the epoxy-terminated end-capping agent and polyetheramine into the reactor according to the material ratio of 1 to 1:1.5, and the epoxy-terminated end-capping agent is 1,1,3,3-tetramethyl-1 , 3 two [3-(oxiranyl methoxy) propyl group] disiloxanes, and add the isopropanol that more than 10g are compared with the total mass of terminal epoxy capping agent and polyether amine, then be warming up to 70 ℃~100℃ for 3~6 hours to obtain polyether modified end-capping agent;

[0026] Step 2: Lower the temperature of the polyether modified end-capping agent obtained in step 1 to 40°C to 45°C, and add octamethylcyclotetrasiloxane (D4) which is 20 to 30 times the mass of the epoxy end-capping agent. Cyclotetrasiloxane, end-epoxy-capping agent, polyetheramine mass sum 1.5% to 5% silane coupling agent with amino grou...

Embodiment 1

[0030] Step 1: Mix the end-epoxy capping agent 1,1,3,3-tetramethyl-1,3 bis[3-(oxiranylmethoxy)propyl]disiloxane and polyetheramine D -2008 according to the material ratio of 1:1.4 into the reactor, and add isopropanol 10g more than the total mass of epoxy-terminated agent and polyetheramine, then raise the temperature to 90 ℃ for 5h, the reaction can be Add a small amount of isopropanol to obtain a polyether modified end-capping agent;

[0031] Step 2: After cooling the polyether modified end-capping agent obtained in step 1 to 40°C, add octamethylcyclotetrasiloxane (D4) 25 times the mass of the epoxy end-capping agent, octamethylcyclotetrasiloxane Oxygen, end-epoxy capping agent, polyether amine quality summation 3% triamine base silane coupling agent, add terminal epoxy end capping agent, polyether amine, D4 and triamine base silane coupling agent gross mass 0.1 % tetramethylammonium hydroxide; evacuate to make the vacuum degree 0.8MPa, raise the temperature to 80°C and k...

Embodiment 2

[0034] Step 1: Mix the end-epoxy blocking agent 1,1,3,3-tetramethyl-1,3 bis[3-(oxiranylmethoxy)propyl]disiloxane and polyetheramine ED -2003 according to the material ratio of 1:1.5 into the reactor, and add isopropanol 10g more than the total mass of epoxy-terminated agent and polyether amine, and then raise the temperature to 100 ℃ for 3h, the reaction can be Add a small amount of isopropanol to obtain a polyether modified end-capping agent;

[0035] Step 2: After cooling the polyether modified end-capping agent obtained in step 1 to 45°C, add octamethylcyclotetrasiloxane (D4) 20 times the mass of the end-epoxy end-capping agent, octamethylcyclotetrasiloxane Oxygen, terminal epoxy-capping agent, polyetheramine mass sum 1.5% vinyl silane coupling agent, add terminal epoxy-capping agent, polyetheramine, D4 and silane coupling agent total mass 0.05% tetramethyl base ammonium hydroxide; evacuate the vacuum to 0.9MPa, raise the temperature to 70°C for 2h to remove small molecule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com