Laser aided rock-breaking fixed gear drill bit

A laser-assisted, fixed-tooth technology, which is applied to drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems that laser technology is not widely used, achieve the effect of destroying the overall strength, reducing the difficulty of rock breaking, and assisting rock breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

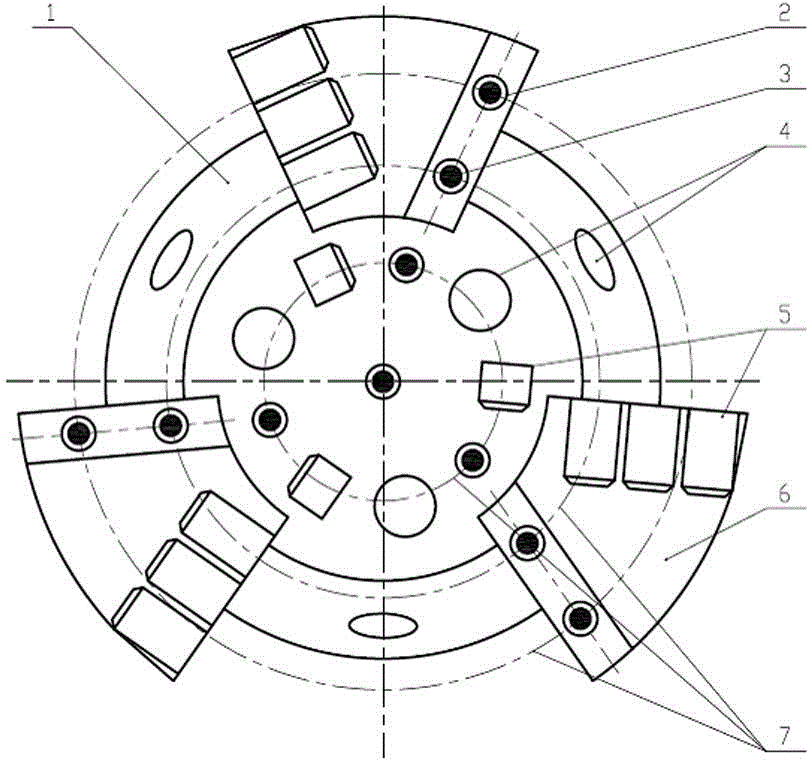

[0013] A fixed-tooth drill bit for laser-assisted rock breaking, mainly composed of a drill body 1, a mud channel 4, a cutting tooth 5, and a blade 6 arranged on the drill body 1, and an optical path channel 2 is also arranged on the drill body 1. A laser head 3 is installed at the end of the channel 2 .

Embodiment 2

[0015] A fixed-tooth drill bit for laser-assisted rock breaking, mainly composed of a drill body 1 and a mud channel 4, a cutting tooth 5 and a blade 6 arranged on the drill body 1, and an optical path channel 2 is also arranged on the drill body 1, and an optical path channel 2 is arranged on the optical path A laser head 3 is installed at the end of the channel 2 . The optical path channels 2 are multi-channel, and are installed on the drill body 1 in circular distribution with different radii around the axis of the drill body 1 . The optical path channel 2 and the mud channel 4 are distributed in isolation from each other along the radial direction.

Embodiment 3

[0017] see figure 1 , the laser-assisted rock-breaking fixed-tooth drill bit has three independent rock-breaking methods: hydraulic, mechanical, and laser, and has an optical path channel 2 independent of the mud channel 4; the optical path channel 2 is equipped with a laser head 3; the fixed-tooth drill bit adopts three blades, Leave as much room as possible on the drill bit to distribute the optical path channel 2; the drill bit adopts a larger-sized composite sheet with a simple envelope design; the distribution of the optical path channel 2 starts from the center of the end face of the drill bit, and gradually moves along the axis of the drill body 1 along the radial direction. Distributed outside, the 9 laser heads installed around naturally form three circles, which are three concentric circles from the top view of the drill bit, which we call the laser ring 7. The laser-assisted rock-breaking fixed-tooth drill bit adopts the strategy that the larger the radius of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com