Automatic liquid level control system for sugarcane juice steaming tank

A technology of automatic liquid level control and evaporation tank, applied in liquid level control, control/regulation system, non-electric variable control, etc., can solve the problems of reducing the heat transfer efficiency of the evaporation system, increasing the labor intensity of employees, and increasing labor intensity, etc. Achieve the effect of improving thermal efficiency, facilitating maintenance and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

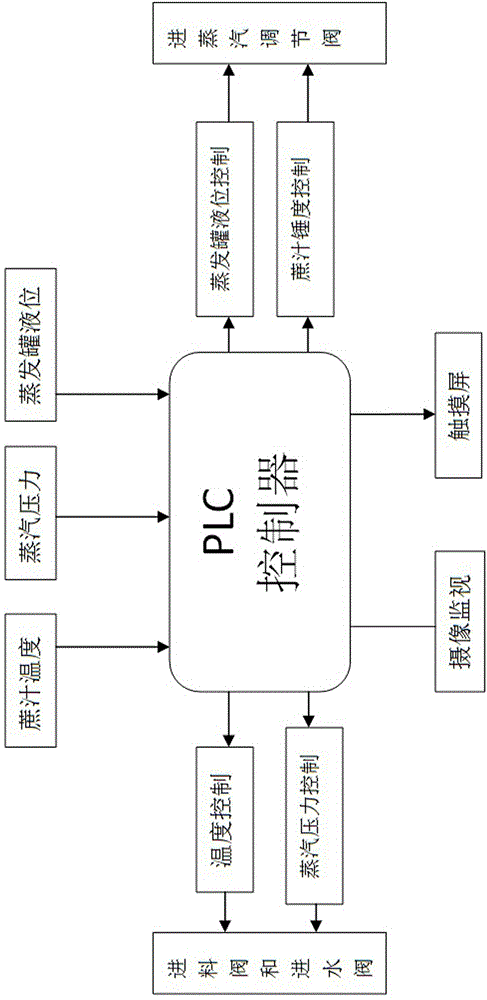

[0019] In this embodiment, a liquid level sensor, a temperature sensor and a steam pressure sensor are arranged in the evaporating tank, a cane juice brix sensor is installed in the evaporating tank accessory device, and a liquid level gauge, a cane juice input pump, an output pump and a steam inlet valve are installed in the evaporating tank. A camera is installed next to the evaporation tank, and a monitoring probe is installed above the evaporation tank. A touch screen, PLC controller and video monitoring equipment are installed in the central operation control room. The liquid level sensor, temperature sensor, steam pressure sensor and hammer sensor are controlled by the transmitter and PLC. Device communication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com