Method for preparing carbon coated nano flaky tin oxide material

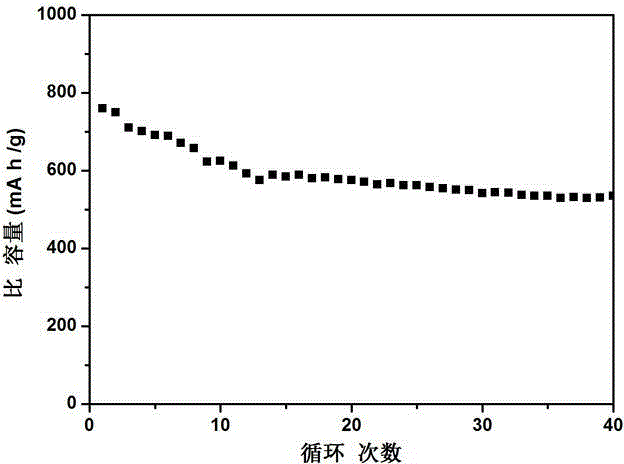

A technology of carbon-coated nano and nano-sheets, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as volume expansion, low specific capacity of electrode materials, and poor cycle performance. Achieve the effects of non-toxic materials, simple and easy experiments, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.005mol of SnCl 2 2H 2 O was added to 100ml of acetylacetone solvent to prepare a 0.05 mol / L tin acetylacetonate solution.

[0028] (2) Take 80 parts of tin acetylacetonate solution with the above configuration of 0.05mol / L, add 20 parts of sodium hydroxide with a mass concentration of 3.2% dropwise, and stir at room temperature for 10 min until a white turbid solution appears.

[0029] (3) Add 50 parts of glucose to the solution obtained in step (2), stir for 20 minutes, and mix well.

[0030] (4) Pour the solution obtained in step (3) into a polytetrafluoroethylene-lined reactor, heat and react in an oven at 180°C for 4 hours, and cool naturally.

[0031] (5) The solution obtained in step (4) was washed with deionized water and ethanol three times in sequence, dried at 60°C for 2h, and then calcined at 450°C for 2h in nitrogen to obtain carbon-coated tin dioxide nanosheets.

Embodiment 2

[0033] (1) Weigh 0.005 mol of stannous 2-ethylhexanoate into 100 ml of ethanol solvent to prepare 0.05 mol / L tin ethoxide solution.

[0034] (2) Take 100 parts of the above-mentioned 0.05 mol / L tin ethoxide solution, add 25 parts of potassium hydroxide with a mass concentration of 3.2% dropwise, and stir at room temperature for 60 min until a white turbid solution appears.

[0035] (3) Add 200 parts of PMMA to the solution obtained in step (2) and stir for 60 minutes, and mix well.

[0036] (4) Pour the solution obtained in step (3) into a polytetrafluoroethylene-lined reactor, heat and react in an oven at 240°C for 8 hours, and cool naturally.

[0037] (5) The solution obtained in step (4) was centrifuged three times with deionized water and ethanol in sequence, dried at 60°C for 2h, and then calcined at 650°C in nitrogen for 7h to obtain carbon-coated tin dioxide nanosheets.

Embodiment 3

[0039] (1) Weigh 0.005 mol of stannous oxalate and add it into 100 ml of ethanol solvent to prepare 0.05 mol / L tin ethanol solution.

[0040] (2) Take 90 parts of the above-mentioned 0.05mol / L tin ethoxide solution, add 22 parts of ammonia water with a mass concentration of 3.2% dropwise, and stir at room temperature for 30 min until a white turbid solution appears.

[0041] (3) Add the solution obtained in step (2) to 100 parts of PMMA and stir for 40 minutes, and mix well.

[0042] (4) Pour the solution obtained in step (3) into a polytetrafluoroethylene-lined reactor, heat and react in an oven at 200°C for 6 hours, and cool naturally.

[0043] (5) The solution obtained in step (4) was washed with deionized water and ethanol three times in sequence, dried at 60°C for 2h, and then calcined at 550°C in nitrogen for 5h to obtain carbon-coated tin dioxide nanosheets.

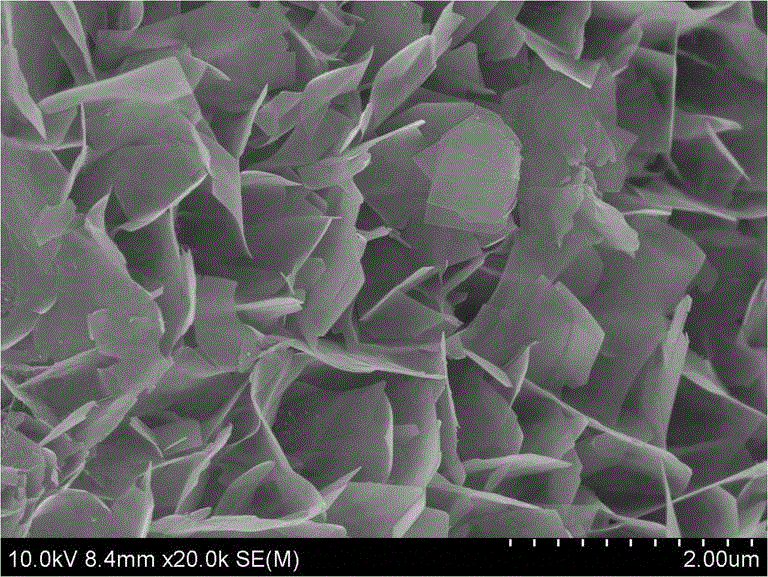

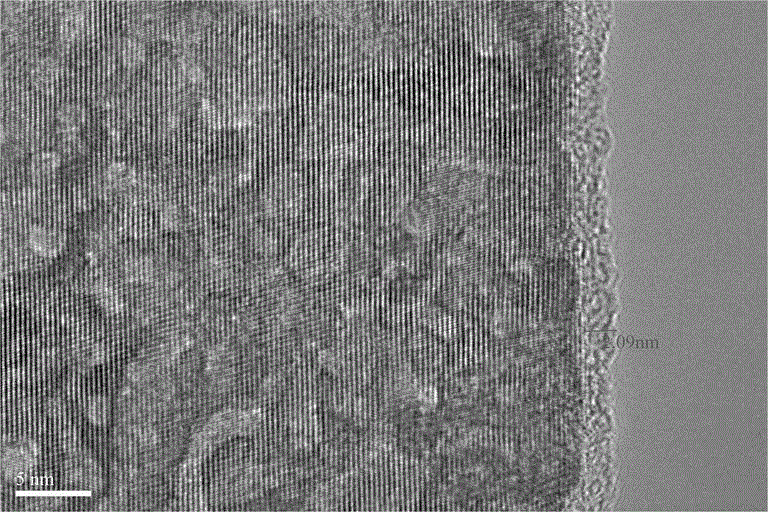

[0044] The results show that the carbon-coated nano-tin dioxide prepared by the present invention is a sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com