Filter medium for removing endosulfan from water as well as filter element and preparation method of filter medium

A filter medium and drinking water technology, applied to chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as high cost, secondary pollution, water and electricity consumption, and achieve simple methods, avoid harm, Easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

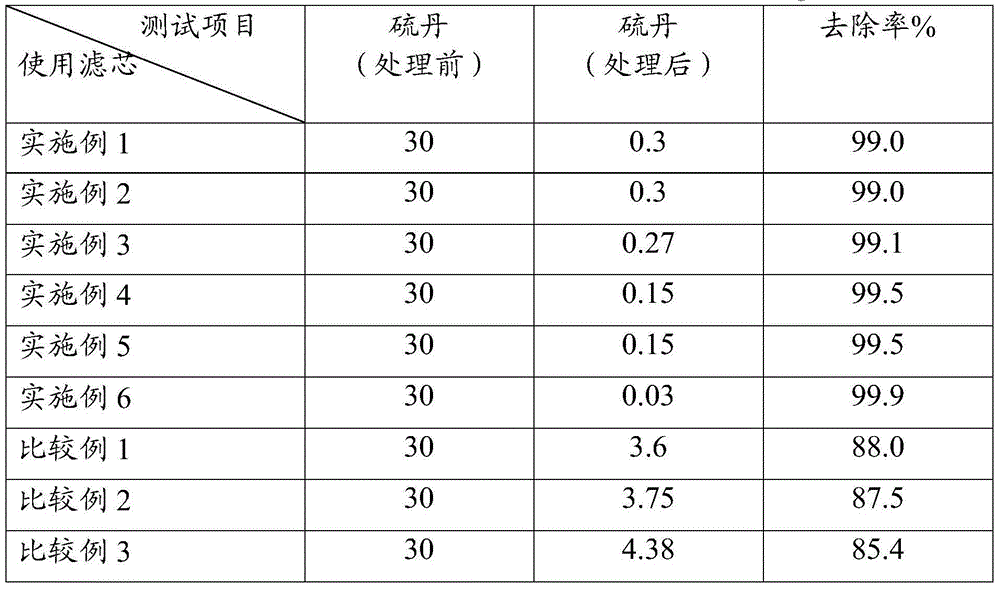

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of the filter medium that removes endosulfan in drinking water, it is characterized in that, comprises the following steps:

[0022] a) mixing ultra-high molecular weight polyethylene powder, activated carbon powder, zeolite molecular sieve powder, attapulgite powder and pore-forming agent to obtain a mixture, the ultra-high molecular weight polyethylene powder, activated carbon powder, zeolite molecular sieve powder, attapulgite powder and foaming agent The weight ratio of the pore agent is 100~300:50~100:100~150:100~150:50~100;

[0023] b) pressing, sintering and cooling the mixture obtained in step a) in a mould.

[0024] The present invention first mixes ultra-high molecular weight polyethylene powder, activated carbon powder, zeolite molecular sieve powder, attapulgite powder and pore-forming agent to obtain a mixture, the ultra-high molecular weight polyethylene powder, activated carbon powder, zeolite molecular ...

Embodiment 1

[0054] (1) Take ultra-high molecular weight polyethylene powder 100g, described ultra-high molecular weight polyethylene is the M-I type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 1.5 million;

[0055] (2) Take by weighing medical active carbon powder 50g, the specific surface area of described medical active carbon is 800m 2 / g;

[0056] (3) Take by weighing 100 g of 13X zeolite molecular sieve powder with a particle diameter of 75 μm;

[0057] (4) Weigh 100g of attapulgite powder, impregnate it with hydrochloric acid with a concentration of 10wt% for 15 hours, filter and extrude into flakes, activate at 300°C for 40 minutes with a drum drier, and pulverize into 100 μm with a decolorizing power of 250. Attapulgite powder;

[0058] (5) Take 50g of pore forming agent;

[0059] (6) Put the above five kinds of powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0060] (7) Fill the mixed pow...

Embodiment 2

[0064] (1) Take ultra-high molecular weight polyethylene powder 200g, described ultra-high molecular weight polyethylene is the M-III type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 3.5 million;

[0065] (2) Take by weighing medical active carbon powder 75g, the specific surface area of described medical active carbon is 1500m 2 / g;

[0066] (3) Take by weighing 125g of zeolite molecular sieve powder with a particle diameter of 80 μm;

[0067] (4) Weigh 125g of attapulgite powder, impregnate it with hydrochloric acid with a concentration of 10wt% for 15 hours, filter and extrude it into pieces, activate it at 300°C for 40 minutes with a drum drier, and pulverize it into an activity of 100 μm with a decolorizing power of 250 Attapulgite powder;

[0068] (5) Take 75g of pore forming agent;

[0069] (6) Put the above five kinds of powders into a spiral agitator and stir for 10 minutes to mix evenly;

[0070] (7) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com