Longitudinal tear detection method and alarm device for capacitive rubber belt conveyer

A belt conveyor, longitudinal tearing technology, applied in the direction of the conveyor control device, conveyor, conveyor objects, etc., can solve the problems of high cost, tape tearing, loss, etc., to prevent the expansion of accidents, convenient installation and construction, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

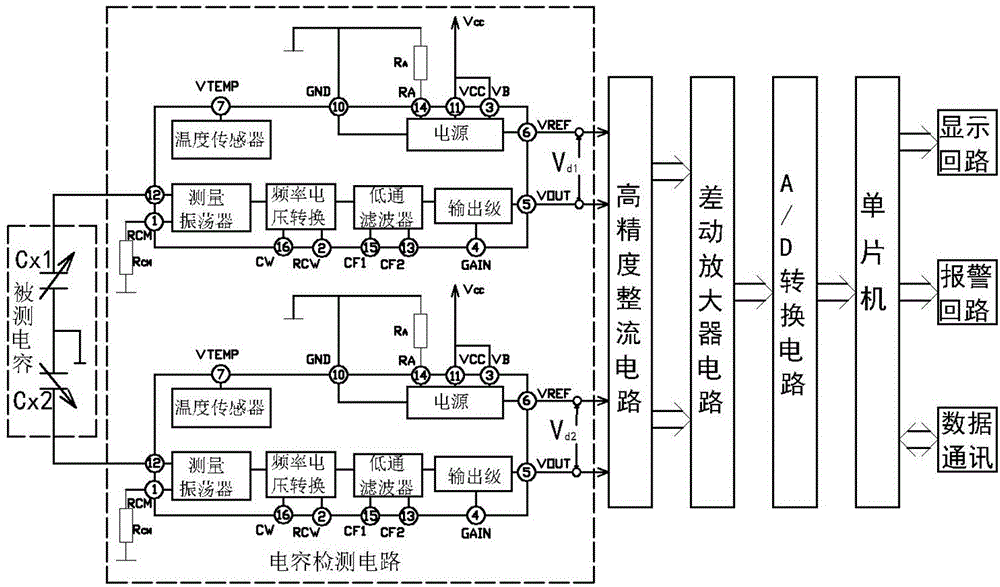

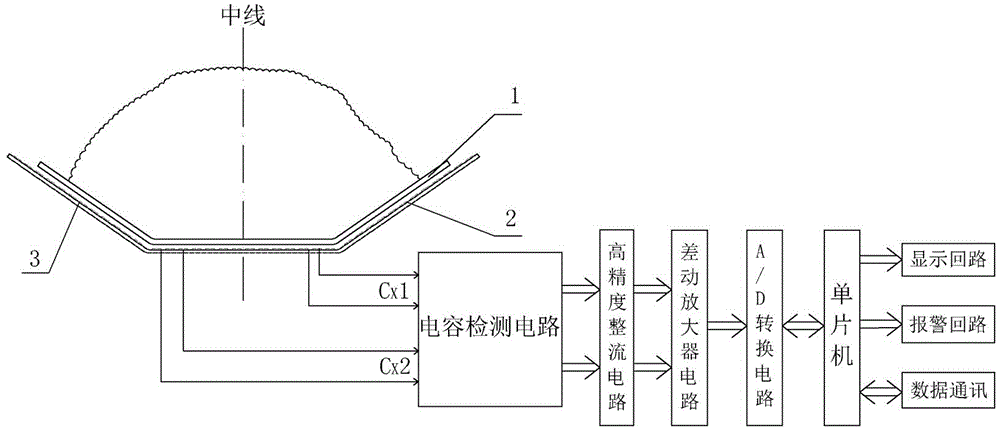

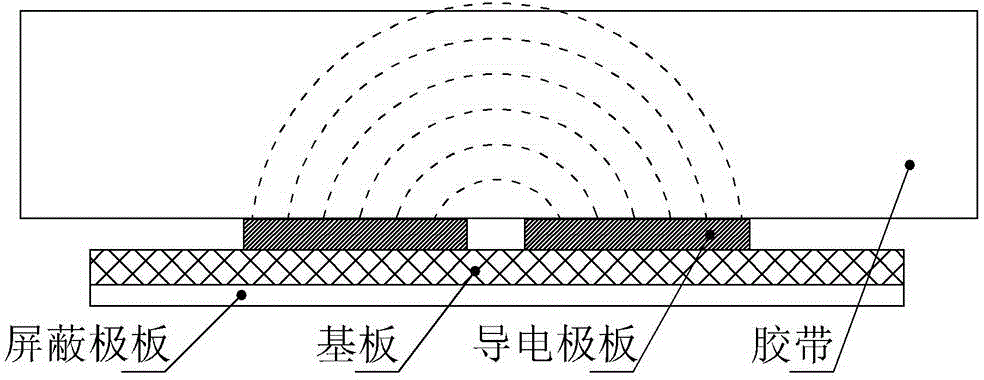

[0021] Such as figure 1 As shown, the present invention provides a kind of capacitive belt conveyor longitudinal tear detection method and alarm device, install and arrange several groups of planar conductive plates below the adhesive tape 1 to form a planar capacitive sensor, and the planar capacitive sensor is connected from the longitudinal centerline of the adhesive tape 1 The processing is divided into two groups of symmetrical and equal planar capacitance sensors 2 and 3, and the planar capacitance sensors 2 and 3 are respectively connected to two capacitance detection circuits. After the oscillator, frequency / voltage conversion circuit and low-pass filter, Cx2 outputs the volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com