A kind of beta and zsm-12 composite molecular sieve and its synthetic method

A ZSM-12, composite molecular sieve technology, applied in the direction of ZSM-12 crystalline aluminum silicate zeolite, molecular sieve and alkali exchange compounds, molecular sieve catalysts, etc. Part damage and other problems, to avoid the decrease of crystallinity, improve the catalytic activity, and improve the physicochemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

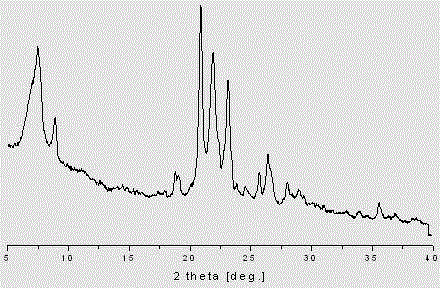

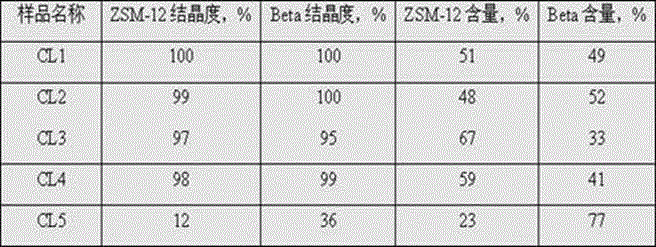

Image

Examples

Embodiment 1

[0035] (1) Dissolve 40 g of glucose in 100 mL of distilled water, add 8 g of ZSM-12 molecular sieves into the glucose solution under stirring conditions, stir for 30 min, place the mixture in an ultrasonic cleaner for 2 h, and then The mixture was filtered, and the obtained product was dried at 120 °C for 12 h, and then calcined at 500 °C for 2 h in a nitrogen atmosphere to obtain a pretreated ZSM-12 molecular sieve.

[0036] (2) Dissolve 0.25 g of sodium hydroxide in 30 mL of 25% TEAOH and stir for 30 min. Then add 0.5 g of sodium aluminate and stir for 30 min. Add 7 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 140 °C for 4 h.

[0037] (3) Mix 5 g of ZSM-12 prepared in step (1) with the pre-crystallized colloid prepared in step (2), and stir for 30 min; then put it into a closed reactor and crystallize in an oven at 140 °C for 10 h. Then the obtained product was washed 4 times with distilled water to ne...

Embodiment 2

[0039] (1) Dissolve 40 g of glucose in 100 mL of distilled water, add 8 g of ZSM-12 molecular sieves into the glucose solution under stirring conditions, stir for 30 min, place the mixture in an ultrasonic cleaner for 2 h, and then The mixture was filtered, and the obtained product was dried at 120 °C for 12 h, and then calcined at 500 °C for 2 h in a nitrogen atmosphere to obtain a pretreated ZSM-12 molecular sieve.

[0040] (2) Dissolve 0.25 g of sodium hydroxide in 30 mL of 25% TEAOH and stir for 30 min. Then add 0.5 g of sodium aluminate and stir for 30 min. Add 6 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 150 °C for 3 h.

[0041] (3) Mix 6 g of ZSM-12 prepared in step (1) with the pre-crystallized colloid prepared in step (2), and stir for 30 min; then close the reactor and crystallize in an oven at 150 °C for 12 h. Then the obtained product was washed 4 times with distilled water to neutrality, t...

Embodiment 3

[0043] (1) Dissolve 35 g of glucose in 100 mL of distilled water, add 7 g of ZSM-12 molecular sieves into the glucose solution under stirring conditions, stir for 30 min, place the mixture in an ultrasonic cleaner for 2 h, and then place the mixture After filtering, the obtained product was dried at 120° C. for 12 h, and then calcined at 550° C. for 1.5 h in a nitrogen atmosphere to obtain a pretreated ZSM-12 molecular sieve.

[0044] (2) Dissolve 0.2 g of sodium hydroxide in 25 mL of 25% TEAOH and 10 mL of distilled water, and stir for 30 min. Then add 0.5 g of aluminum nitrate and stir for 30 min. Add 7 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 150 °C for 2 h.

[0045] (3) Mix 8 g of ZSM-12 prepared in step (1) with the pre-crystallized colloid prepared in step (2), and stir for 30 min; then put it into a closed reaction kettle, and crystallize in an oven at 150 °C for 52 h. Then the obtained produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com