Micro-aerobic biological treatment device for low-C/N-ratio manure dry-collection pig farm wastewater and method for treating pig farm wastewater

A technology of microaerobic organisms and treatment devices, which is applied in the fields of animal husbandry wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of incomplete treatment technology, large infrastructure investment, and high operating costs. Achieve the effects of simple structure, low investment and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

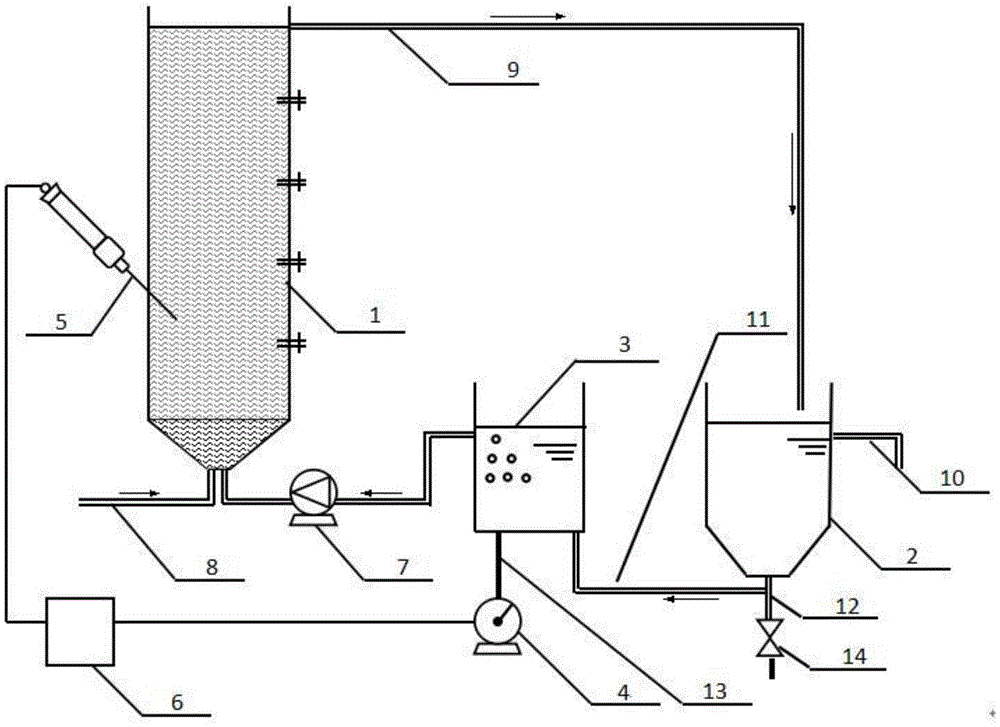

[0018] Specific implementation mode one: combine figure 1 Illustrate this embodiment, the microaerobic biological treatment device of a kind of low C / N ratio dry pig farm waste water of this embodiment is composed of microaerobic reactor 1, sedimentation tank 2, muddy water dissolved oxygen pool 3, air blower 4, dissolved oxygen Sensor 5, air volume controller 6, sludge return pump 7, micro-oxygen reactor inlet pipe 8, micro-oxygen reactor outlet pipe 9, sedimentation tank outlet pipe 10, sludge return pipe 11, excess sludge discharge pipe 12, exposure Trachea 13 and valve 14 are formed; The top of described micro-oxygen reactor 1 is provided with micro-oxygen reactor water outlet pipe 9, and the mouth of mouth of described micro-oxygen reactor water outlet pipe 9 is arranged on the top of described sedimentation tank 2, so The upper part of the sedimentation tank 2 is provided with a sedimentation tank outlet pipe 10, and the bottom water outlet of the sedimentation tank 2 is...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that: the upper part of the micro-oxygen reactor 1 is a cylinder, and the lower part is a cone, the height of which is 500 mm, and the diameter of the cylinder is 100 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the sedimentation tank 2 is an inverted triangular pyramid with a height of 200 mm and a diameter of 380 mm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com