Advanced nitrogen and phosphorus removal technology

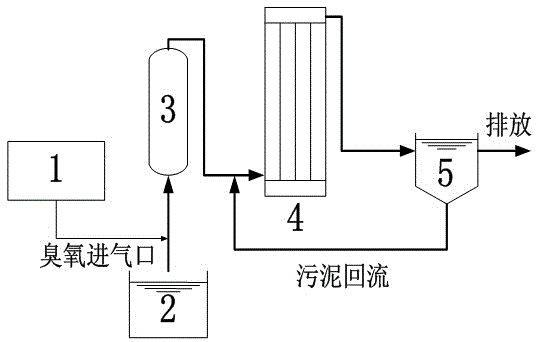

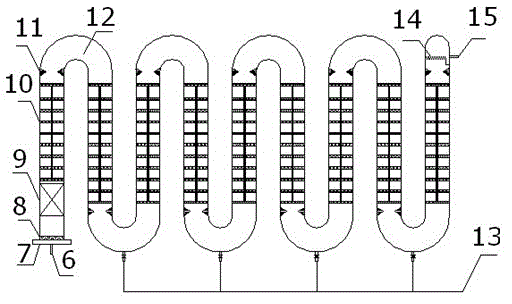

A deep denitrification and process technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problem of increased operating costs and management difficulties, and is not suitable for large-scale industrial applications. and other problems, to achieve the effect of stable denitrification and phosphorus removal, improved biodegradability, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The treatment method of the present invention is used to conduct an advanced treatment test on the secondary biochemical effluent of a domestic urban sewage treatment plant. The water quality of the urban sewage treatment plant after secondary biochemical treatment is as follows: biochemical effluent COD 80-120 mg / L, pH 7.2-7.5, ammonia nitrogen 10-25 mg / L, total nitrogen 35-48 mg / L, chroma 175 ~200 degrees, BOD 5 0~5 mg / L, total phosphorus 1~5 mg / L.

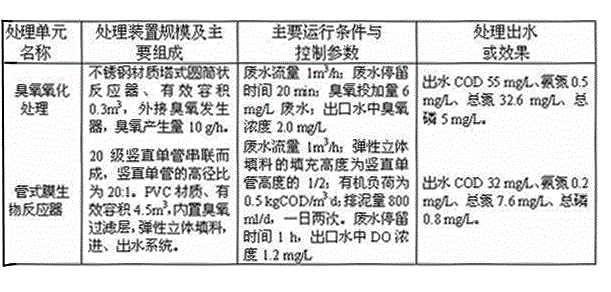

[0024] Adopt the method of the present invention, carry out combination treatment test to above-mentioned waste water. Wastewater treatment scale is 1m 3 / h, the main test device configuration, operating conditions and treatment effects of each treatment unit are shown in Table 1. After being treated by the method of the present invention, the effluent index can meet the water quality requirements of industrial reuse water, that is, COD ≤ 35 mg / L, ammonia nitrogen ≤ 1 mg / L, total nitrogen ≤ 10 mg / L, and total phosphor...

Embodiment 2

[0028] The treatment device of Example 1 was used to treat the same sewage as in Example 1, and the wastewater treatment effects obtained by changing the operating conditions of each treatment unit are shown in Table 2.

[0029] Table 2 Main processing unit composition and processing effect of embodiment 2

[0030]

Embodiment 3

[0032]The treatment device of Example 1 was used to treat the same sewage as in Example 1, and the wastewater treatment effects obtained by changing the operating conditions of each treatment unit are shown in Table 3.

[0033] Table 3 Main processing unit composition and processing effect of embodiment 3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com