Preparation method of besifloxacin hydrochloride

A technology of besifloxacin hydrochloride and quinoline carboxylic acid, which is applied in the field of compound preparation, can solve problems such as expensive, difficult to reproduce, and difficult to obtain, and achieve the effects of less impurities, easy operation, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

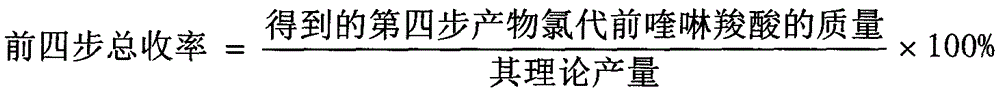

[0041] See figure 1 , which is a synthetic route diagram of the preparation method of besifloxacin hydrochloride in the embodiment of the present invention, and the synthetic route diagram does not include the resin activation step of step (1).

[0042] The preparation method of besifloxacin hydrochloride provided by the present invention first connects 1-cyclopropyl-6,7-difluoro-8-chloro-1,4-dihydro-4-oxo-3-quinoline carboxylic acid Activated 4-(bromomethyl)phenoxymethyl polystyrene resin with (R)-3-tritylaminohexahydroazepine The resin obtained by solid phase condensation is cracked under acidic conditions and the protective group trityl group is removed simultaneously to obtain (R)-7-(3-aminohexahydro-1H-aza -1-yl)-1-cyclopropyl-6-fluoro-1,4-dihydro-4-oxo-3-carboxylic acid quinoline, and then chlorinated under the effect of thionyl chloride to form (R )-7-(3-Aminohexahydro-1H-aza -1-yl)-1-cyclopropyl-6-fluoro-1,4-dihydro-4-oxo-3-carboxylic acid quinoline hydrochloride...

Embodiment 1

[0044] The preparation method of the besifloxacin hydrochloride that the embodiment of the present invention provides, comprises the following steps:

[0045] (1) Resin activation: take 13 g of 4-(bromomethyl) phenoxymethyl polystyrene resin, place it in anhydrous DMF to expand for 1.5 h, and then wash it twice with anhydrous DMF;

[0046] 4-(bromomethyl) phenoxymethyl polystyrene resin is from Novabiovchem company #01-64-0186, 150 mesh, 1.2meq / gram;

[0047] (2), preparation of quinoline carboxylic acid resin: add 180mL DMF to the activated resin in step (1), then add 4g 1-cyclopropyl-6,7-difluoro-8-chloro-1,4-dihydro-4 - Oxygen-3-quinoline carboxylic acid, treated with cesium carbonate, stirred at room temperature for 2 h, filtered with 50% DMF / water mixture, DMF, methanol and DCM, washed 3 times in turn, and filtered the obtained quinoline carboxylic acid resin ;

[0048] (3) Solid phase condensation: Add quinoline carboxylic acid resin to 200mL DCM / DMF mixture, add 20g (...

Embodiment 2

[0054] The preparation method of the besifloxacin hydrochloride that the embodiment of the present invention provides, comprises the following steps:

[0055] (1) Resin activation: take 10 g of 4-(bromomethyl) phenoxymethyl polystyrene resin, place it in anhydrous DMF to expand for 1 hour, and then wash it with anhydrous DMF for 4 times;

[0056] 4-(bromomethyl) phenoxymethyl polystyrene resin is from Novabiovchem company #01-64-0186, 100 mesh, 1.2meq / gram;

[0057] (2), preparation of quinoline carboxylic acid resin: add 200mLDMF to the activated resin in step (1), then add 5g 1-cyclopropyl-6,7-difluoro-8-chloro-1,4-dihydro-4 - Oxygen-3-quinoline carboxylic acid, treated with cesium carbonate, stirred at room temperature for 2 hours, filtered with 50% DMF / water mixture, DMF, methanol and DCM, washed twice and then filtered to obtain quinoline carboxylic acid resin;

[0058] (3) Solid phase condensation: Add quinoline carboxylic acid resin to 250mL DCM / DMF mixture, add 30g (R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com