Preparation method of nanocellulose/polyurethane foam composite elastomer

A technology of polyurethane foam and nanocellulose, which is applied in the field of preparation of cellulose composite materials, can solve the problems of inability to rebound, poor elastic properties of cellulose foam/aerogel, etc., achieve good cushioning function, stable performance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

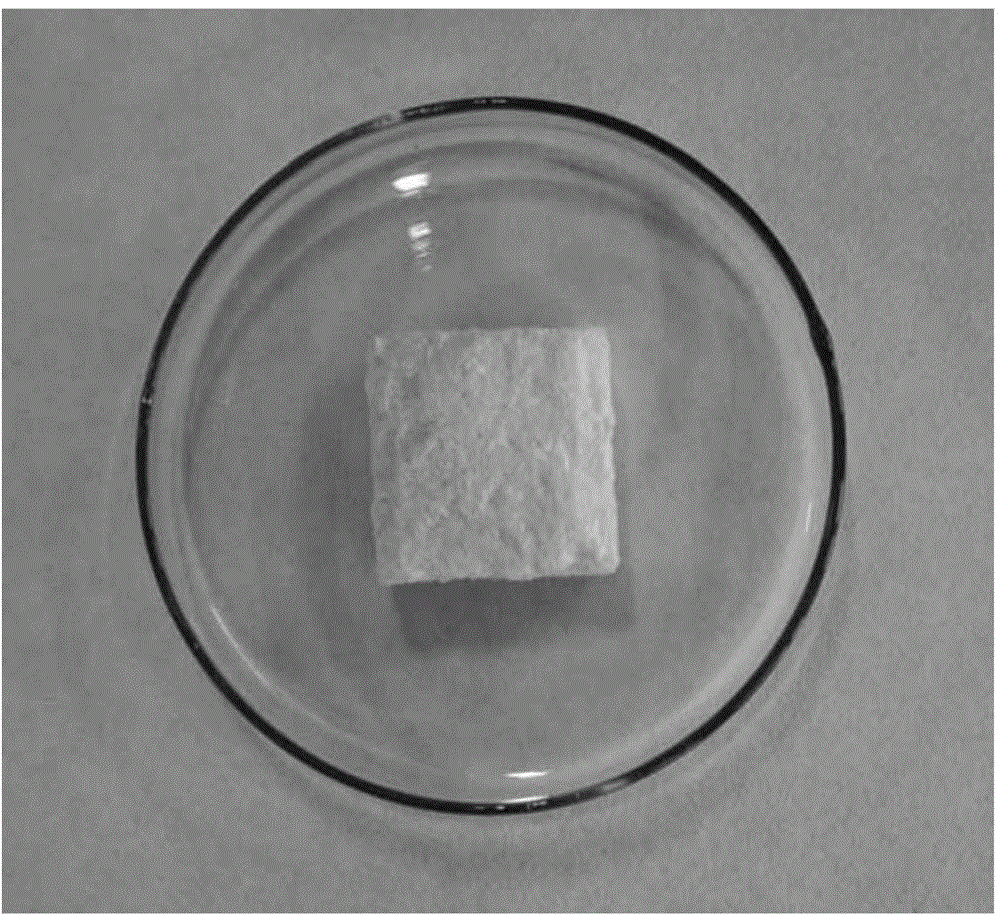

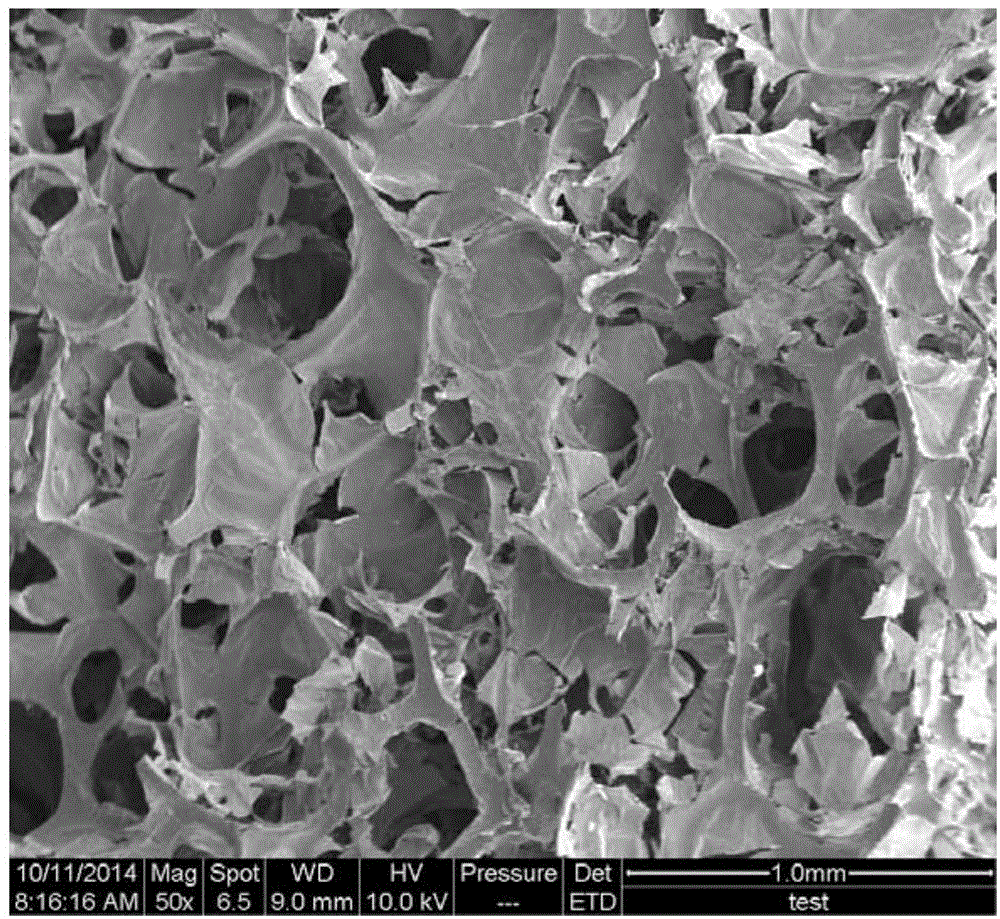

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment 1: The method for preparing a nano-cellulose / polyurethane foam composite elastomer of this embodiment is specifically carried out according to the following steps:

[0022] 1. The cellulose resource is made into powder, subjected to Soxhlet extraction, and then added to distilled water and mixed uniformly to obtain a solid-liquid mixture;

[0023] 2. Add the solid-liquid mixture obtained in step 1 to the acidified sodium chlorite solution, and control the temperature to be 50-100°C under a constant temperature water bath for 0.5-2h to obtain a mixture;

[0024] 3. Repeat step 2 2-10 times, and then clean;

[0025] 4. Add the mixture obtained in step 3 to the alkaline solution, let it stand for 8-12 hours, then control the temperature to 70-100°C, keep it for 1-5 hours, then wash and drain, and then perform cleaning and suction filtration to obtain purified cellulose ;

[0026] 5. The purified cellulose obtained in step 4 is subjected to mechanical defibrillat...

specific Embodiment approach 2

[0029] Specific embodiment two: This embodiment is different from specific embodiment one in that the cellulose resource in step one is lignocellulose resource. Others are the same as the first embodiment.

[0030] Lignocellulosic resources include wood, bamboo, cotton, hemp and agricultural and forestry management residues, as well as biological materials containing cellulose such as bacterial cellulose and ascidians.

specific Embodiment approach 3

[0031] Specific embodiment three: This embodiment is different from the specific embodiment one in that the extraction temperature is controlled to 90°C in step one. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com