A kind of preparation method of water-soluble brown natural pigment in camellia oleifera seed dregs

A technology of natural pigments and Camellia oleifera seed meal, which is applied in the direction of natural dyes, sugar derivatives preparation, chemical instruments and methods, etc., can solve the problems of waste, less utilization of camellia oleifera seeds, and discarded residues, and achieve the effect of solving the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

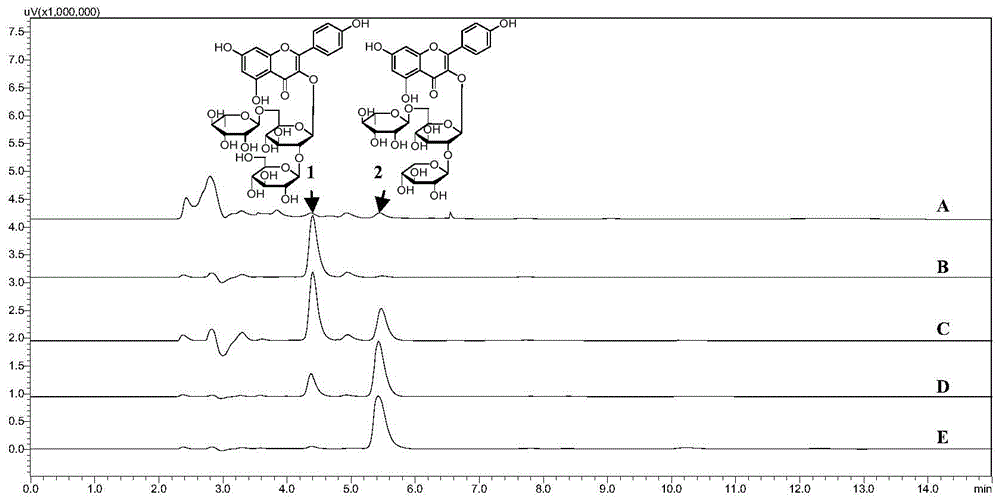

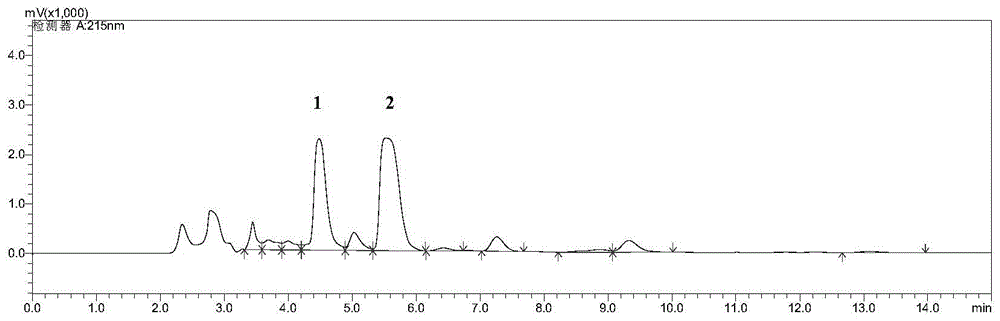

Image

Examples

Embodiment 1

[0026] (1) Grind 50g of Camellia oleifera seed meal with a grinder to a particle size of 30 mesh, put it into a reflux extraction tank, add 125mL of 60% edible alcohol, heat and reflux for extraction for 2 hours, filter after cooling, and put the filter residue into the extraction tank repeatedly Add 125mL of 60% edible alcohol to extract for 2 hours, cool and filter, combine the filtrate, and concentrate the filtrate to dryness with a rotary evaporator at 45°C to obtain about 14g of extract.

[0027] (2) Take 50 g of polyamide filler (100-200 mesh), fill it in a glass chromatographic column with an inner diameter of 3 cm × 60 cm long, and equilibrate the chromatographic column with distilled water;

[0028] (3) Take 1 g of the sample obtained in step 1, dissolve it completely with a small amount of distilled water, load it on the polyamide chromatography column packed in step 2, wash it with 0.1% acetic acid solution at a flow rate of 25 ml / min, and use 500 ml as the volume T...

Embodiment 2

[0032] (1) Grind 100g of Camellia oleifera seed meal with a pulverizer to a particle size of 20 mesh, put it into an ultrasonic extractor and add 250mL of 95% edible alcohol, set the temperature at 45°C, and ultrasonically extract at an ultrasonic frequency of 40KHz for 1 hour, filter, and filter the residue Repeat the extraction twice under the same conditions in an ultrasonic extractor, filter, combine the filtrate, and concentrate the filtrate to dryness with a rotary evaporator at 45°C to obtain about 25 g of the extract.

[0033] (2) Take 60 g of polyamide filler (30-60 mesh), fill it in a glass chromatographic column with an inner diameter of 3 cm × 60 cm long, and equilibrate the chromatographic column with distilled water;

[0034] (3) Take 1 g of the sample obtained in step 1, dissolve it with a small amount of distilled water, and load it on the polyamide chromatography column packed in step 2

[0035] (4) Carry out elution with the mobile phase that contains edible al...

Embodiment 3

[0038] (1) Grind 100g of Camellia oleifera seed meal with a pulverizer to a particle size of 80 mesh, put it into an ultrasonic extractor and add 250mL of 95% edible alcohol, set the temperature at 45°C, and ultrasonically extract at an ultrasonic frequency of 40KHz for 1 hour, filter, and filter the residue Repeat the extraction twice under the same conditions in an ultrasonic extractor, filter, combine the filtrate, and concentrate the filtrate to dryness with a rotary evaporator at 45°C to obtain about 25 g of the extract.

[0039] (2) Take 55g of polyamide filler (60-90 mesh), fill it in a glass chromatographic column with an inner diameter of 3cm x 60cm long, and equilibrate the chromatographic column with distilled water;

[0040] (3) Take 1 g of the sample obtained in step 1, dissolve it with a small amount of distilled water, and load it on the polyamide chromatography column packed in step 2.

[0041] (4) Carry out elution with the mobile phase that contains edible al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com