Aqueous coating agent for electronic component and manufacturing method of processing electronic component

A technology for electronic components and manufacturing methods, which can be used in the manufacture of printed circuits, coatings, electrical components, etc., can solve problems such as problems with organic solvents, and achieve excellent durability, high water and oil repellency, and high antifouling properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

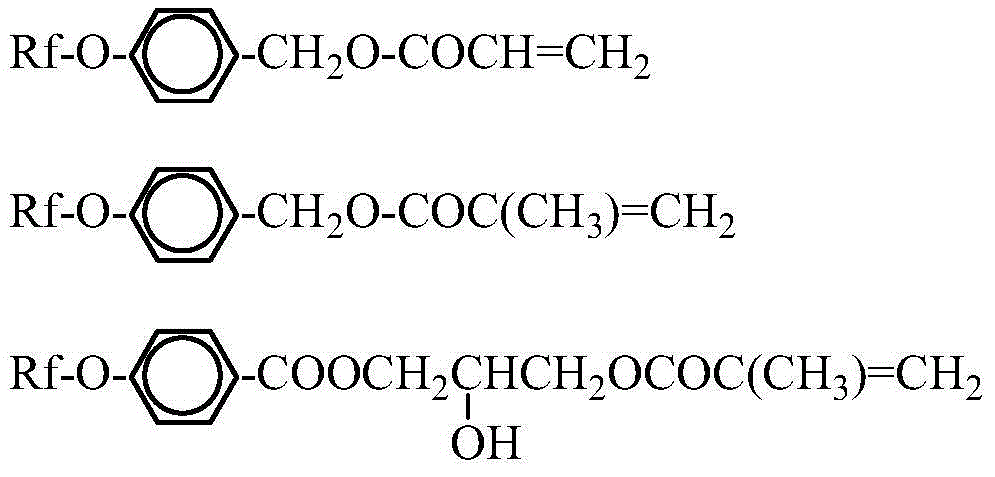

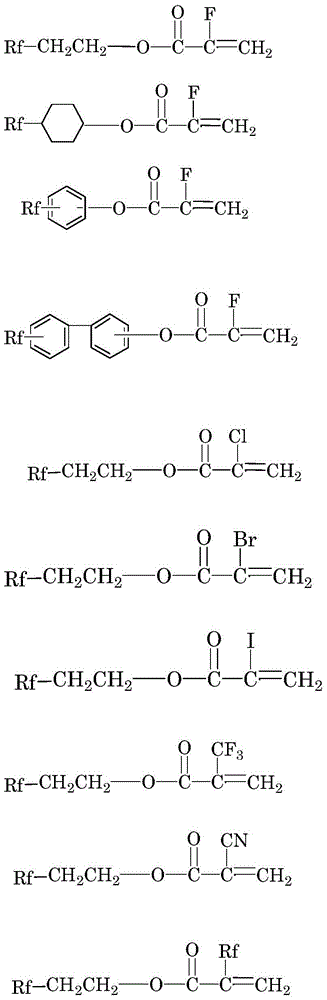

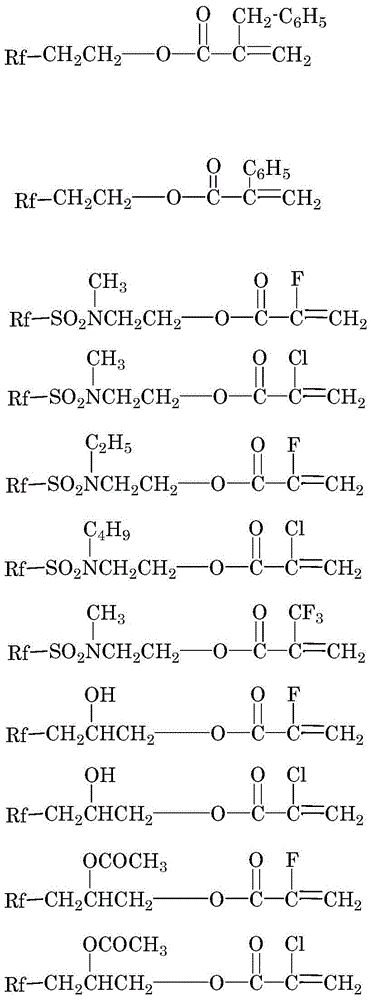

Method used

Image

Examples

Embodiment

[0153] Hereinafter, although an Example and a comparative example are shown, and this invention is demonstrated concretely, these are only the specific examples of this invention, and this invention is not limited to these. Hereinafter, unless otherwise specified, % means % by weight.

[0154] The test methods and measurement methods used in the present invention and the following examples are as follows.

[0155] (1) Water repellent and oil repellent

[0156] The water and oil repellency of the copper foil portion of the test piece was evaluated using a contact angle meter (manufactured by Kyowa Interface Science Co., Ltd., CONTACT-ANGLE METER CA-DT).

[0157] (2) Resistance value

[0158] The surface resistance of the test piece was measured using a resistance measuring machine (manufactured by Advantest Co., Ltd., ULTRA HIGH RESISTANCE METER R8340A).

[0159] (3) Water resistance

[0160] The test pieces were immersed in deionized water at 25°C for 24 hours. The surfac...

manufacture example 1

[0165] Production Example 1 (Preparation of "Rf(C6)-DM" Polymer Aqueous Solution)

[0166] Stir and dissolve 73.30g CF in a four-neck flask 3 CF 2 -(CF 2 CF 2 ) 2 -CH 2 CH 2 O COC (CH 3 )=CH 2 [Rf (C6) methacrylate], 26.70g of dimethylaminoethyl methacrylate (DM), 150.00g of isopropanol (IPA), while nitrogen replacement, while maintaining at 60°C, add 2g of over tert-butyl oxypivalate was reacted at 60°C for 6 hours to obtain a polymer solution. At the end of the polymerization reaction, it was confirmed by gas chromatography that the monomer conversion rate reached 99% or more. Further, while stirring the polymer solution at 60° C., 10.20 g of CH 3 A mixed solution of COOH (acetic acid) and 300g of ion-exchanged water. Thereafter, IPA was removed under reduced pressure, and the solid content of the solution was determined from the evaporation residue after heating at 130° C. for 1 hour, and diluted with ion-exchanged water so that the solid content was 25 mass%, to...

manufacture example 2

[0167] Production Example 2 [Rf(C4)Cl-DM] and Production Example 3 [Rf(C2)-DM]

[0168] In Manufacturing Example 1, replace Rf(C6) methacrylate and DM with 63.00g CF respectively 3 CF 2 CF 2 CF 2 -CH 2 CH 2 OCOC(Cl)=CH 2 Except [Rf(C4) chloroacrylate] and 37.00 g of DM, it manufactured by the same method completely, and made the obtained product into manufacture example 2. Also, replace all but 59.62g CF with 3 CF 2 -CH 2 OCOC (CH 3 )=CH 2 [Rf(C2) methacrylate] and 40.38 g of DM were obtained in exactly the same manner as Production Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com