Biodegradable additive for improving property of PVA-substituted sizing agent

A technology of biodegradation and auxiliaries, applied in the field of textile auxiliaries, to achieve the effect of excellent biodegradability and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of biodegradable auxiliary agent for improving the performance of PVA substitute slurry is prepared by the following process steps:

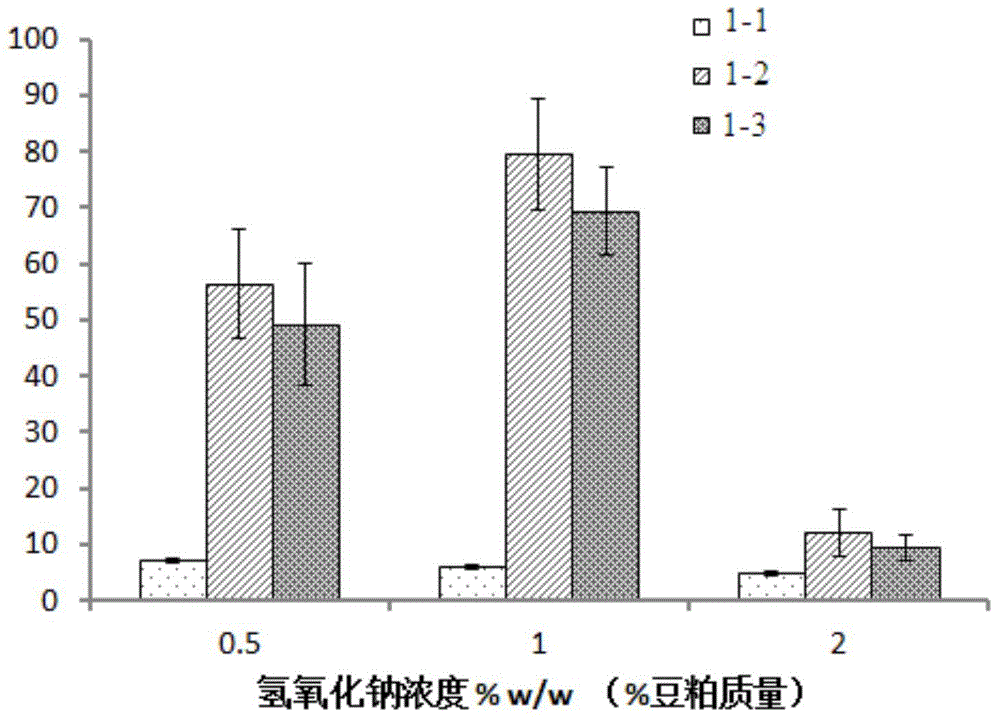

[0034] Mix soybean meal with 0.5%, 1% and 2% sodium hydroxide solution in a mass ratio of 1:7.5 respectively, and after heating at 90°C for 1 hour, filter out the undissolved solid matter; use Adjust pH to 8 with 37% hydrochloric acid to obtain soybean meal-based adjuvant.

[0035] Mix 10 grams of soybean protein with 90 grams of 0.01% sodium hydroxide solution, heat and stir at 90°C for 30 minutes, adjust the pH to 7 with 37% hydrochloric acid, and obtain a soybean protein solution. At this time, the soybean meal additives obtained by treating with different concentrations of sodium hydroxide were added to the soybean protein solution, and the soybean meal additives with different alkali extraction conditions accounted for 5% of the soybean protein mass, and were uniformly stirred for 5 minutes to obtain a mixed solu...

Embodiment 2

[0036] Embodiment 2: A kind of biodegradable auxiliary agent for improving the performance of PVA substitute slurry is prepared by the following process steps:

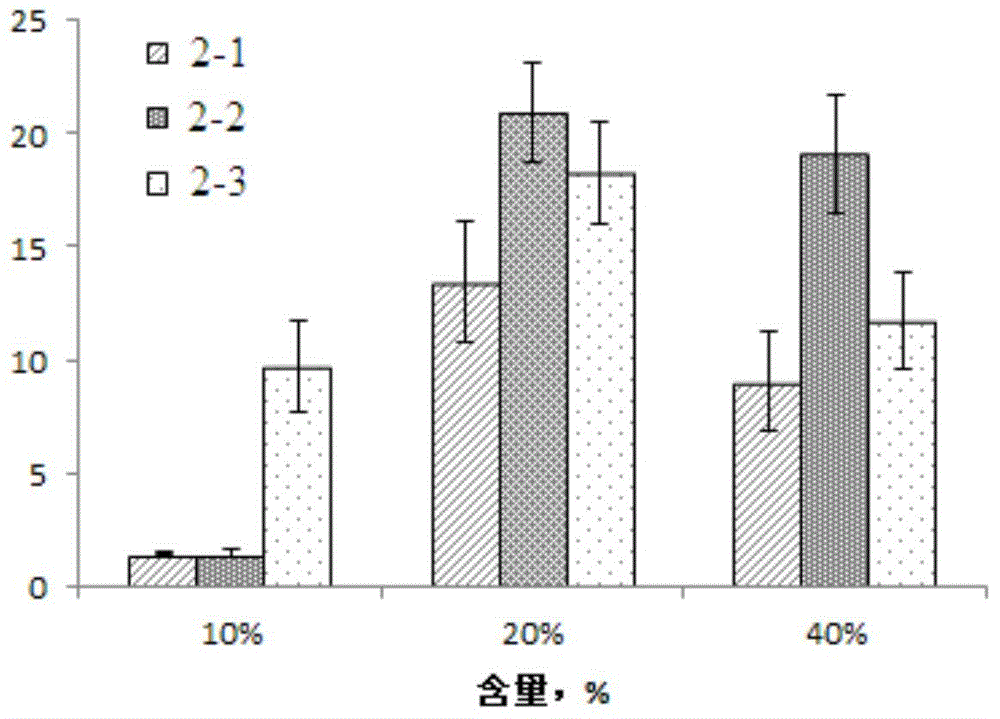

[0037] (1) Mix soybean oil with 50% sodium hydroxide solution in a mass ratio of 1:1, heat at 100°C for 3 hours. Use 37% hydrochloric acid to adjust the pH to 8 to obtain the soybean oil-based adjuvant.

[0038] Mix 10 grams of soybean protein with 90 grams of 0.01% sodium hydroxide solution by mass, heat and stir at 90°C for 30 minutes, and adjust the pH to 7 with 37% hydrochloric acid to obtain a soybean protein solution. At this point, add soybean oil-based additives corresponding to 10%, 20% and 40% of the mass of the soybean protein solution to the soybean protein solution, raise the temperature to 90° C. and stir evenly for 5 minutes to obtain a mixed solution. The mixed solution was poured into a polytetrafluoroethylene-coated mold and left at room temperature for 48 hours to form a slurry film. Although the ...

Embodiment 3

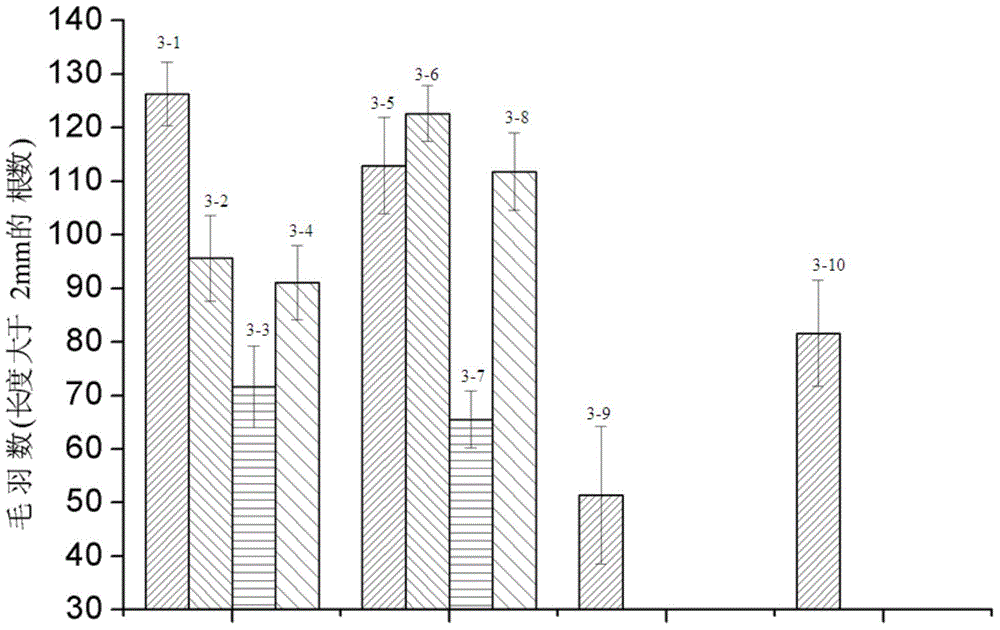

[0039] Embodiment 3: A kind of biodegradable auxiliary agent for improving the performance of PVA substitute slurry is prepared by the following process steps:

[0040] To avoid the use of more expensive ethanol solutions, alkaline solutions can be used to dissolve gluten and distiller's grains. Mix gluten and corn distiller's grains with 0.5% lye in a mass ratio of 1:7.5, heat at 90°C for 1 hour, filter to obtain gluten and corn distiller's grains solution, and adjust the pH to 8. Obtain alkali-soluble gluten and distiller's grains-based additives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com