Advancing waterstop sedimentation post-cast strip of foundation slab

A technology of foundation floor and post-casting belt, applied in basic structure engineering, water conservancy engineering, underwater structure, etc. Waterproof and water-stop effect, small crack development range, effect of enhancing shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

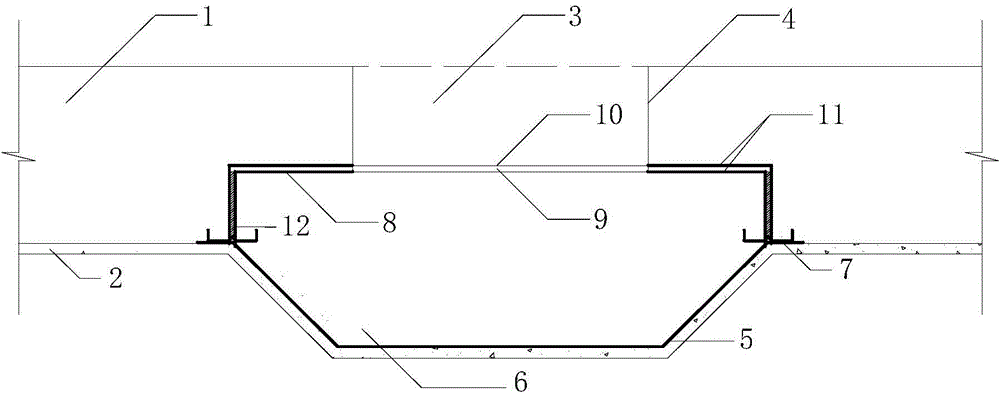

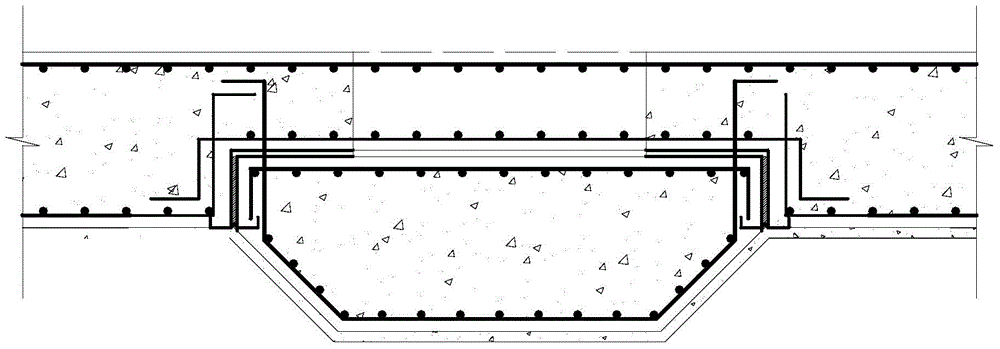

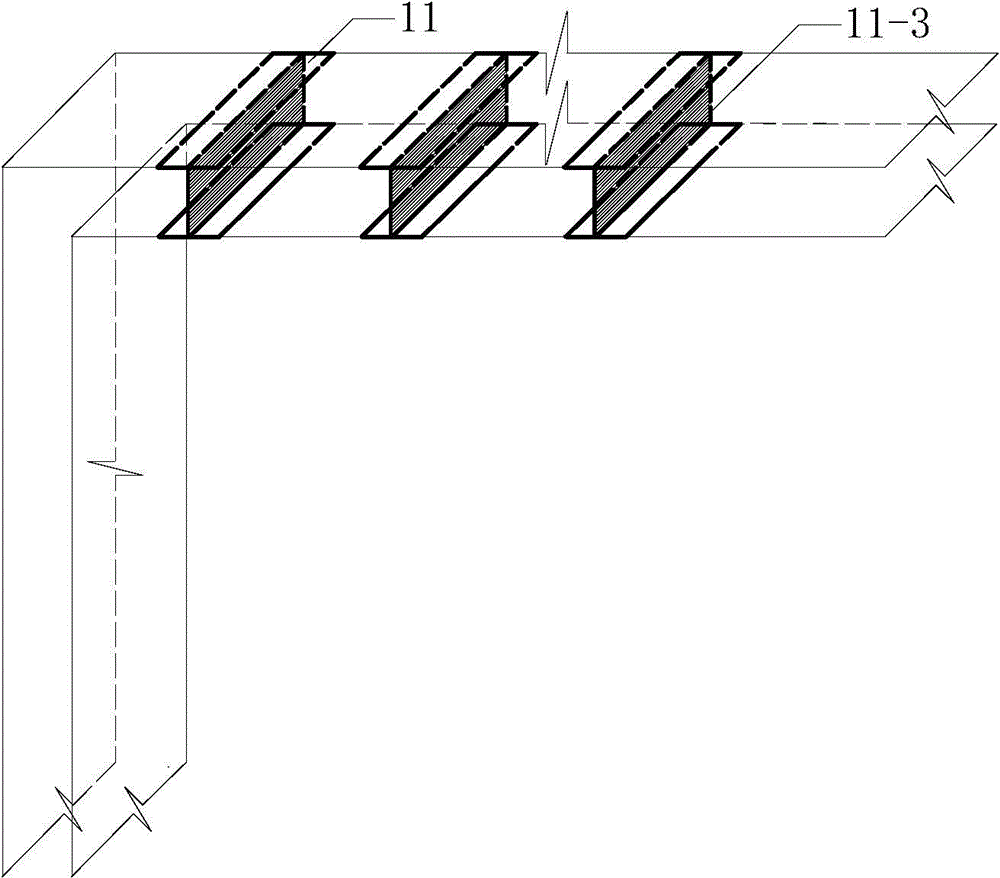

[0031] combine Figure 1 to Figure 5 , the post-pouring belt of the foundation base plate of the present invention includes a base plate 1, a post-casting belt 3 located at the place where the post-cast concrete is placed on the foundation base plate 1, and an advanced water-stop and water-proof member 6 located at the lower part of the post-casting belt 3; the base base plate 1 and the advanced water-stop and water-proof member 6 and the foundation cushion 2 are laid with a waterproof coiled material 5, and the junction of the foundation bottom plate 1 and the post-casting belt 3 is laid with a quick-easy closing net 4;

[0032] The advanced water-stop and water-proof member 6 is an integral structure, and there are right-angled expansion joints 8 between the two sides of the upper part and the base plate 1, the width of the expansion joints 8 is not greater than 40mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com