A multi-fan super bypass ratio turbine thrust system

A bypass ratio and multi-fan technology, applied in the field of multi-fan ultra-large bypass ratio turbine thrust system, can solve the problems of reducing aircraft flight speed, increasing engine noise, and low durability, so as to achieve large operating margin and improve bypass ratio. ratio, low emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

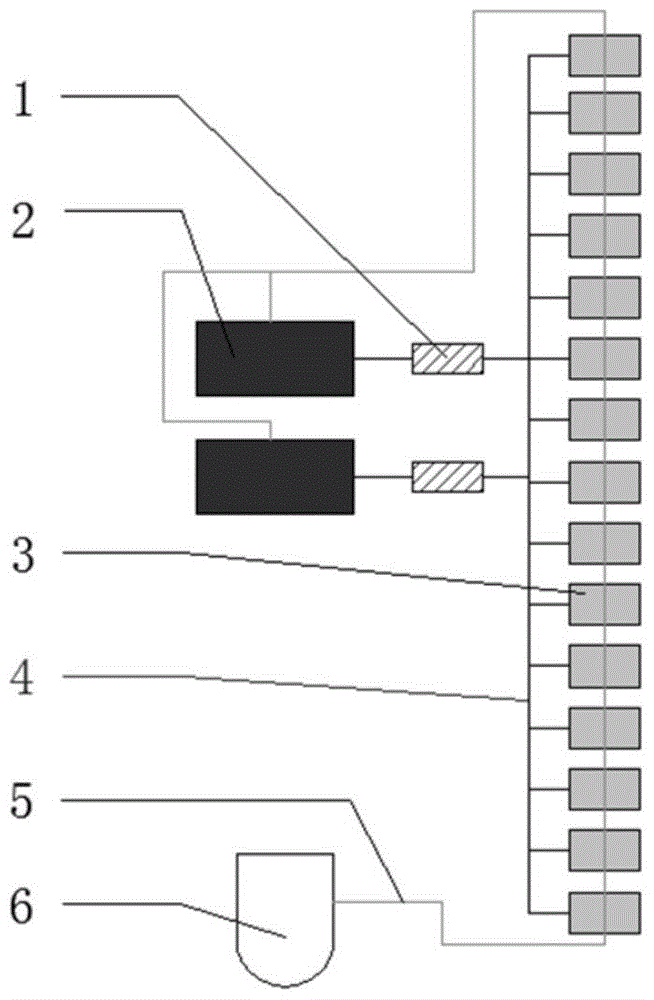

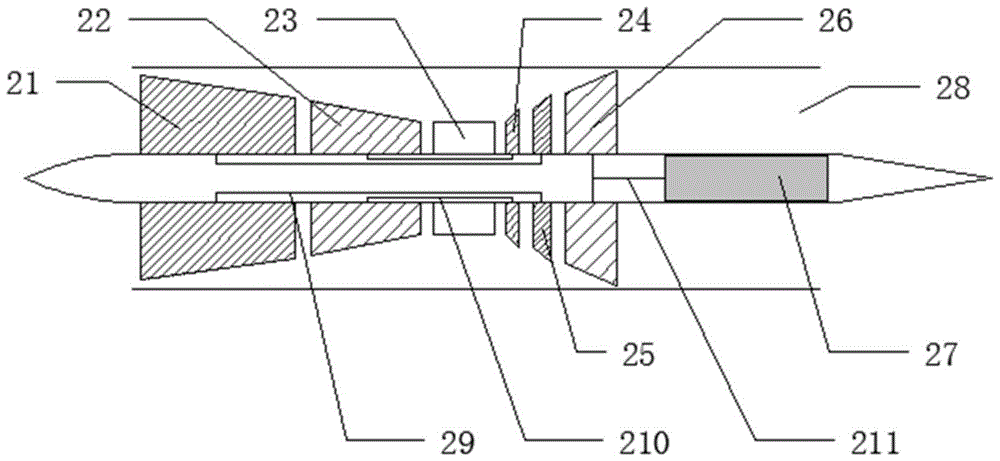

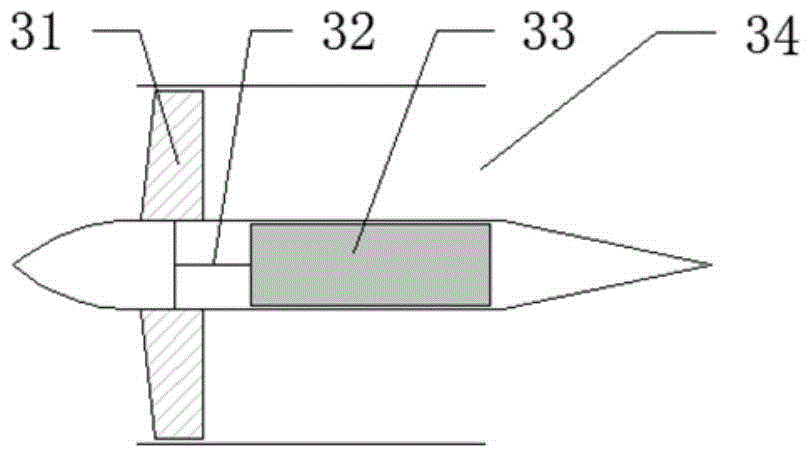

[0045] Such as Figures 1 to 3 Shown, the multi-fan ultra-large bypass ratio turbine propulsion system of the present invention mainly consists of 2 low-pressure compressors 21, high-pressure compressors 22, combustion chambers 23, high-pressure turbines 24, intermediate turbines 25, power turbines 26, and main nozzles 28. Gas turbine-generator mechanism unit 2 composed of generator 27; 15 motor-fan propulsion units 3 composed of fan 31, motor 33 and outer nozzle 34; 2 INVERTER frequency converters 1; conductive cable 4, fuel out book The pipeline 5 and the liquid hydrogen storage tank 6 are composed. The gas passes through the compressor and the combustion chamber to generate high-temperature and high-pressure gas, which then drives the power turbine to work. This part of energy can generate electric energy by driving the motor 27 , or directly generate thrust through the main nozzle 28 . The generated electric energy is transmitted to the motor 33 through the frequency con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com