Method for determining content of Al, Ca and Fe in highly pure nanometer ITO powder

A technology for the content of aluminum and iron in powder, applied in the field of determination of impurity element content, can solve the problems of long process, high detection limit, inappropriate impurity elements, etc., and achieve the effect of low detection limit, easy to grasp and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific embodiments.

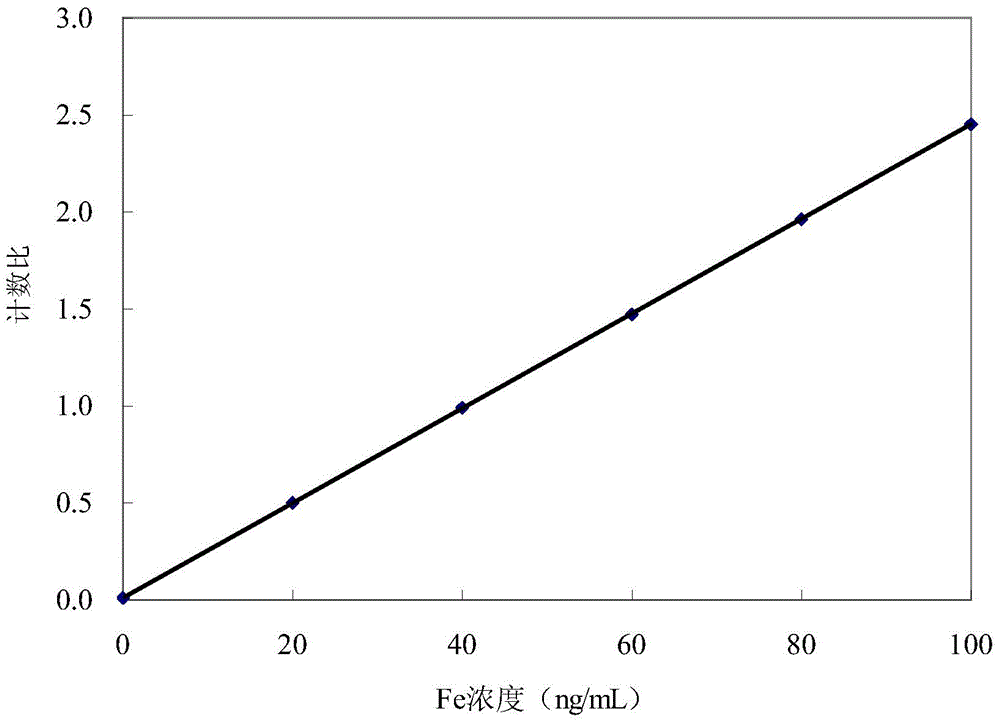

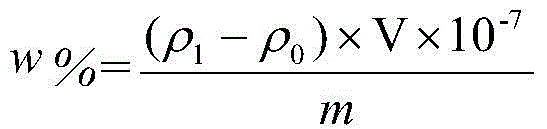

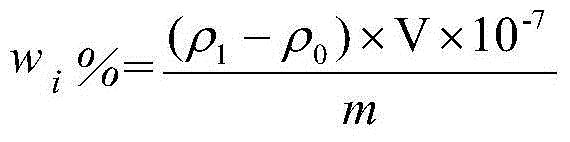

[0036] The present invention uses microwave digestion to process the sample, and uses an inductively coupled plasma mass spectrometer to measure the content of Al, Ca, and Fe in high-purity nano-ITO. The test experiment of the present invention is carried out in a high-purity laboratory, and the specific steps are as follows:

[0037] 1. Sample pretreatment

[0038] Weigh 0.1g of high-purity nano-ITO sample, accurate to 0.0001g, into a polytetrafluoroethylene digestion tank, add 2mL of concentrated hydrochloric acid and 1mL of concentrated nitric acid, use microwave digestion for sample pretreatment, and do a blank test with the sample.

[0039] The temperature control procedure for microwave digestion is as follows:

[0040] In the first step, it takes 10 minutes to raise the temperature to 120°C and keep it for 10 minutes;

[0041] In step 2, heat up to 180°C in 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com