Analysis method for determining furfural content in extract oil and raffinate oil extracted by aromatic hydrocarbons

A technology for extracting aromatics and extracting oil, which is applied in the direction of analyzing materials, measuring devices, material separation, etc., to achieve the effect of simple operation, high precision and good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

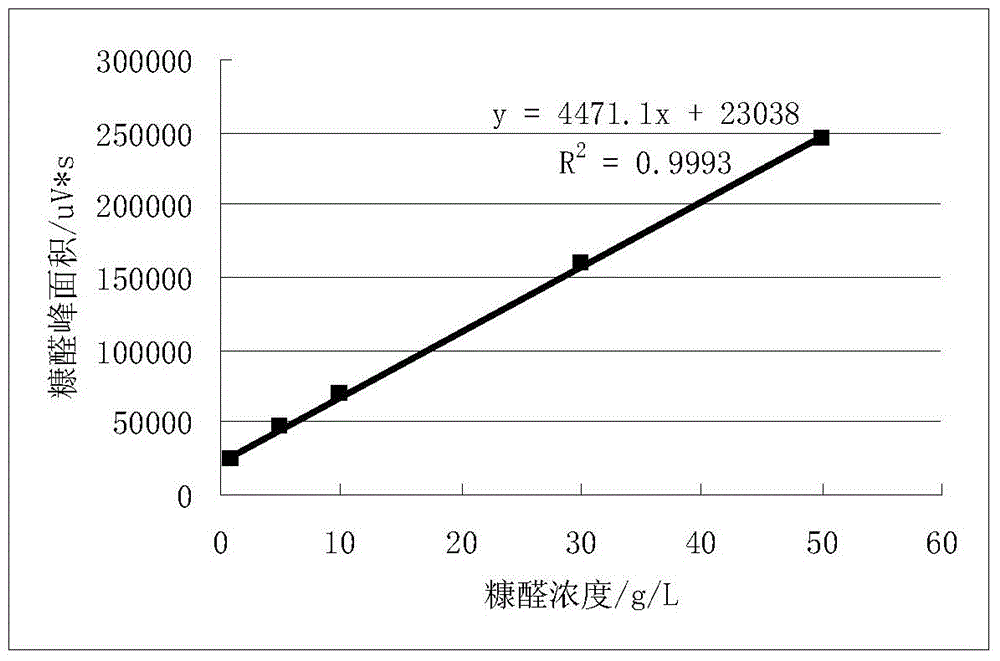

[0068] The establishment of embodiment 1 standard curve

[0069] The analysis conditions are as follows:

[0070] Chromatographic column: stainless steel packed column, 2.4m×3.2mm, fixed solution is 1% SP-1000 (TPA modified polyethylene glycol), and support is 60 / 80 mesh Carbopack B.

[0071] Carrier gas: high-purity nitrogen N 2 , 40mL / min;

[0072] Combustion gas: high-purity hydrogen H 2 , 40mL / min;

[0073] Supporting gas: purified compressed air Air, 400mL / min;

[0074] Injection port temperature: 200°C;

[0075] Column temperature: Initial temperature is 180°C, raised to 200°C at 5°C / min, kept for 3 minutes, then raised to 240°C at 40°C / min;

[0076] Detector temperature: 300°C;

[0077] Balance: Sensitivity is 0.0001g;

[0078] Sample: 4g;

[0079] Formaldehyde: 4mL;

[0080] Constant temperature water bath: 60°C

[0081] Injection volume: 1uL.

[0082] Considering that in the production of heavy aromatics extraction, the content of furfural in catalytic oil...

Embodiment 2

[0086] The investigation of embodiment 2 precision

[0087] Under the analysis condition identical with embodiment 1, with the standard solution that furfural mass concentration is 3.00g / L, measure 6 times, the standard deviation that measures is 0.15g / L, and relative standard deviation is 5.0%; The mg / L standard solution was measured 6 times, the standard deviation was 1.77 mg / L, and the relative standard deviation was 4.4%.

Embodiment 3

[0088] Embodiment 3 standard addition recovery test

[0089] Add 0.050 g of furfural standard substance into 3.950 g of oil slurry to prepare sample A, and its furfural concentration is 1.25% (% (m / m)). Add 0.150g standard substance to 3.850g of extracted oil with a furfural concentration of 0.50% (% (m / m)), prepare sample B, and its furfural concentration is 4.23% (% (m / m)).

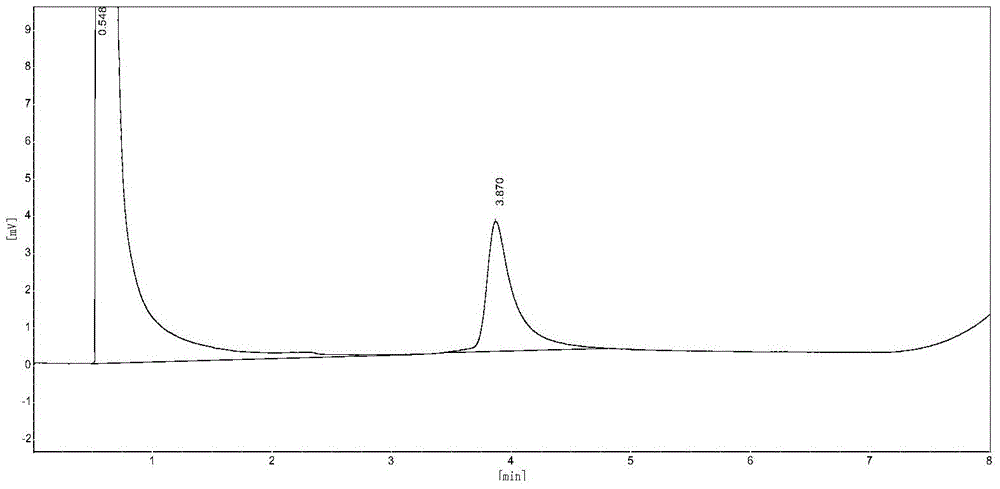

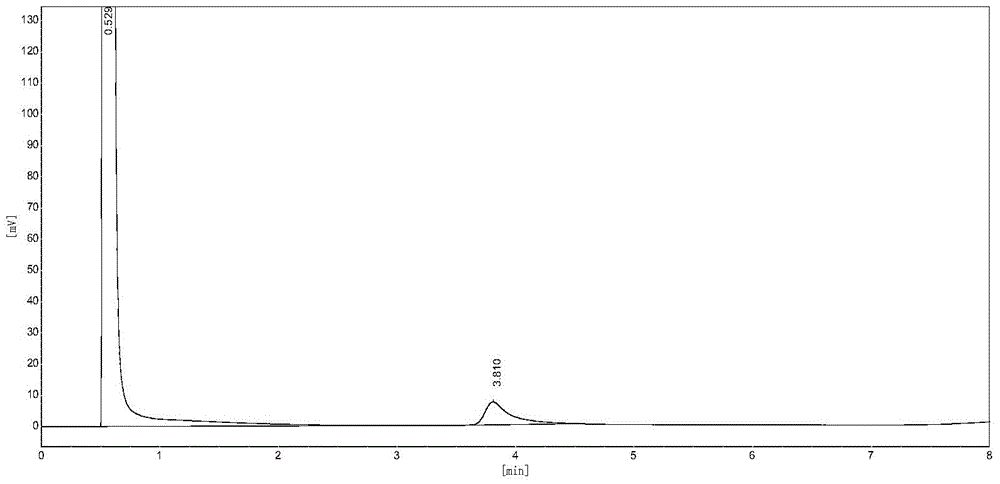

[0090] Under the same analytical conditions as in Example 1, sample A and sample B were pretreated, and the two preparations were measured 6 times respectively, and the furfural contained in the two samples was subjected to a standard addition recovery experiment, and the results are shown in the table 2. Table 3, the relative standard deviation of the determination is Figure 4 It is the analysis chromatogram of the methanol extraction sample of sample B. The retention time of the furfural chromatographic peak is 3.831min. It can be seen that the furfural analysis of the oil sample has no interference....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com