A kind of lead carbon electrode and preparation method thereof

An electrode, lead-carbon technology, applied in the field of electrodes, can solve the problems of detrimental battery cycle life, industrial scale difficulty, life problems, etc., and achieve the effects of good capacity retention, reduced sulfation, and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

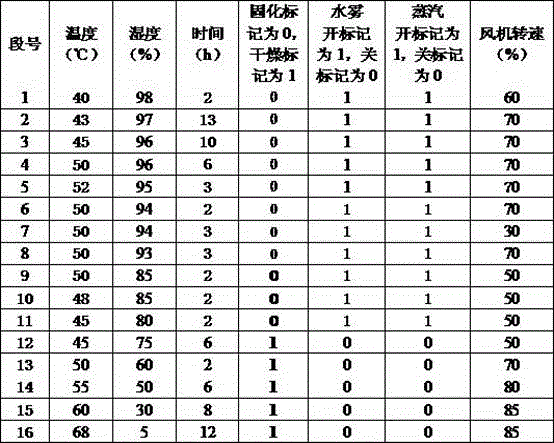

Image

Examples

Embodiment 1

[0034] Embodiment 1 selects lead powder 100kg for use:

[0035] A lead-carbon electrode, comprising mixed carbon, carrier, expansion agent, compatibilizer, nano-carbon lead, lead powder, lead powder in the above-mentioned composition is basic component; Mixed carbon is 1kg, wherein graphite 0.4kg, Acetylene black 0.3kg, activated carbon 0.2kg, artificial carbon 0.1kg; Carrier is 1kg, the mass ratio of silicon and carbon in the carrier is 2:1; 1 kg; the expansion agent is composed of a mixture of barium sulfate, lignin, humic acid, and carbon nanotubes, 0.8 kg of barium sulfate, 0.2 kg of lignin, 0.3 kg of humic acid, and 0.1 kg of carbon nanotubes kg.

[0036] A preparation method for a lead-carbon electrode, comprising the steps of:

[0037] Step 1, prepare raw materials:

[0038] Select 100kg of lead powder and 0.1kg of sodium polyaspartate for standby;

[0039] Select graphite 0.4kg, acetylene black 0.3kg, activated carbon 0.2kg, artificial carbon 0.1kg powder to mix to...

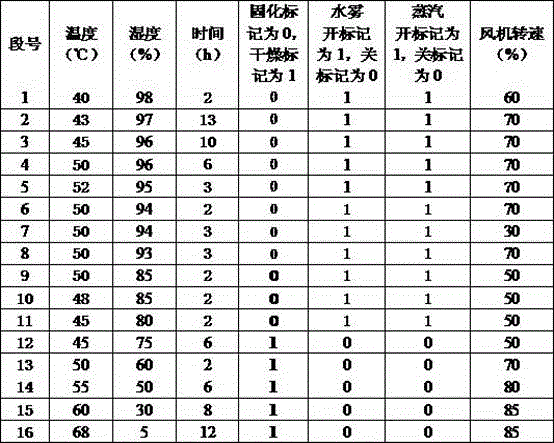

Embodiment 2

[0057] Embodiment 2 selects lead powder 100kg for use:

[0058] A lead-carbon electrode, comprising mixed carbon, carrier, expansion agent, compatibilizer, nano-carbon lead, lead powder, lead powder in the above-mentioned composition is basic component; Mixed carbon is 3kg, wherein graphite 1.2kg, Acetylene black 0.9kg, activated carbon 0.6kg, artificial carbon 0.3kg; Carrier is 2kg, the mass ratio of silicon and carbon in the carrier is 2:1; 2 kg; the expansion agent is composed of a mixture of barium sulfate, lignin, humic acid and carbon nanotubes, 1 kg of barium sulfate, 0.2 kg of lignin, 0.4 kg of humic acid, and 0.1 kg of carbon nanotubes kg.

[0059] A preparation method for a lead-carbon electrode, comprising the steps of:

[0060] Step 1, prepare raw materials:

[0061] Select 100kg of lead powder and 0.3kg of sodium polyaspartate for standby;

[0062] Select graphite 1.2kg, acetylene black 0.9kg, activated carbon 0.6kg, artificial carbon 0.3kg powder to mix to ob...

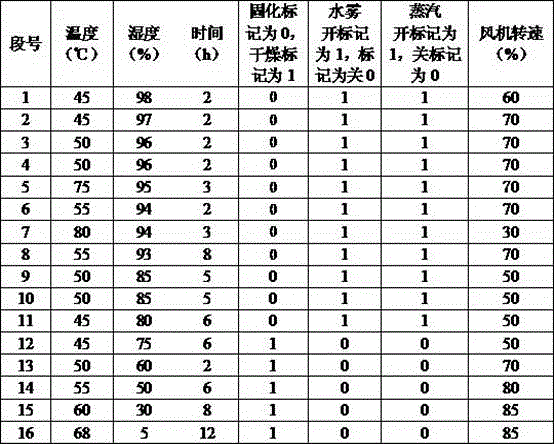

Embodiment 3

[0080] Embodiment 3 selects lead powder 100kg for use:

[0081] A lead-carbon electrode comprising mixed carbon, carrier, expansion agent, compatibilizer, nano-carbon lead, lead powder, lead powder in the above-mentioned composition is basic component; mixed carbon is 2kg, wherein graphite 0.8kg, Acetylene black 0.6kg, activated carbon 0.4kg, artificial carbon 0.2kg; the carrier is 1.5kg, the mass ratio of silicon and carbon in the carrier is 2:1; the expansion agent is 1.6 kg, the compatibility aid is 0.2 kg, nano-carbon lead 1.5 kg; the expansion agent is a mixture of barium sulfate, lignin, humic acid, and carbon nanotubes. Barium sulfate is 0.9 kg, lignin is 0.2 kg, humic acid is 0.4 kg, and carbon nanotubes is 0.1 kg.

[0082] A preparation method for a lead-carbon electrode, comprising the steps of:

[0083] Step 1, prepare raw materials:

[0084] Select 100kg of lead powder and 0.2kg of sodium polyaspartate for standby;

[0085] Select graphite 0.8kg, acetylene blac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com