MBR (membrane bioreactor) water treatment system and method by siphon water production

A water treatment system and siphon technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems that hinder the application and promotion of MBR technology, and increase the operating cost of the process, and achieve The membrane separation effect is good, the operation cost is reduced, and the effect of reducing the operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

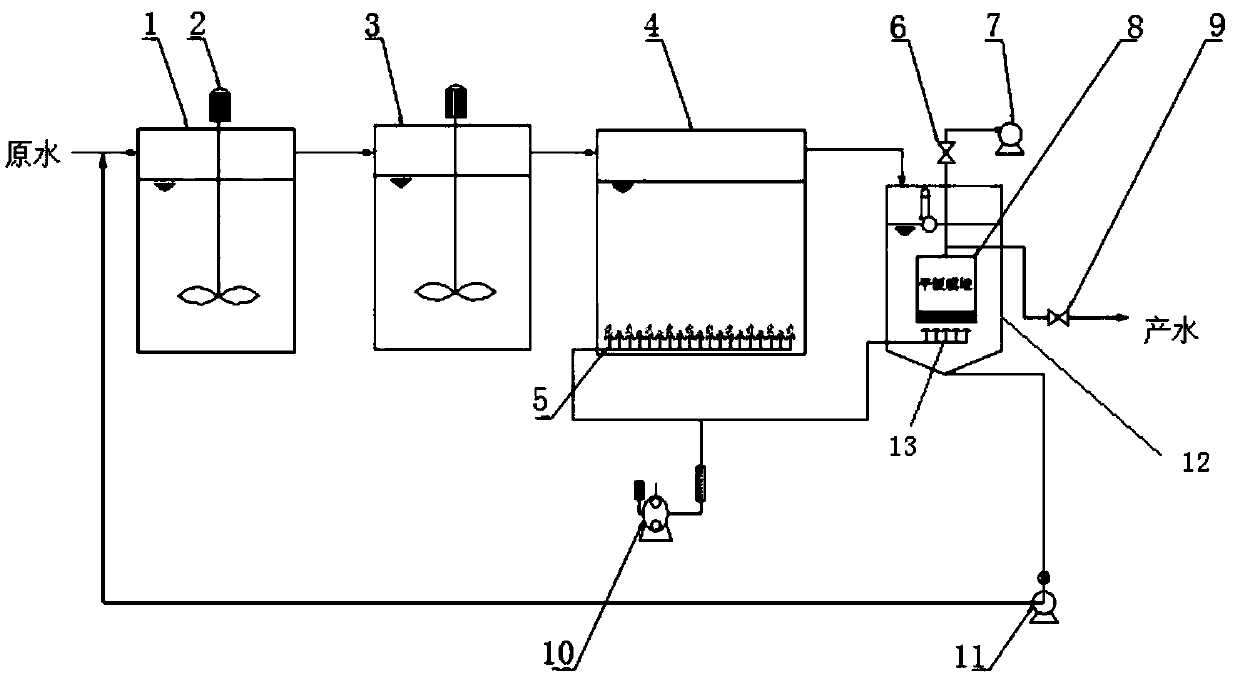

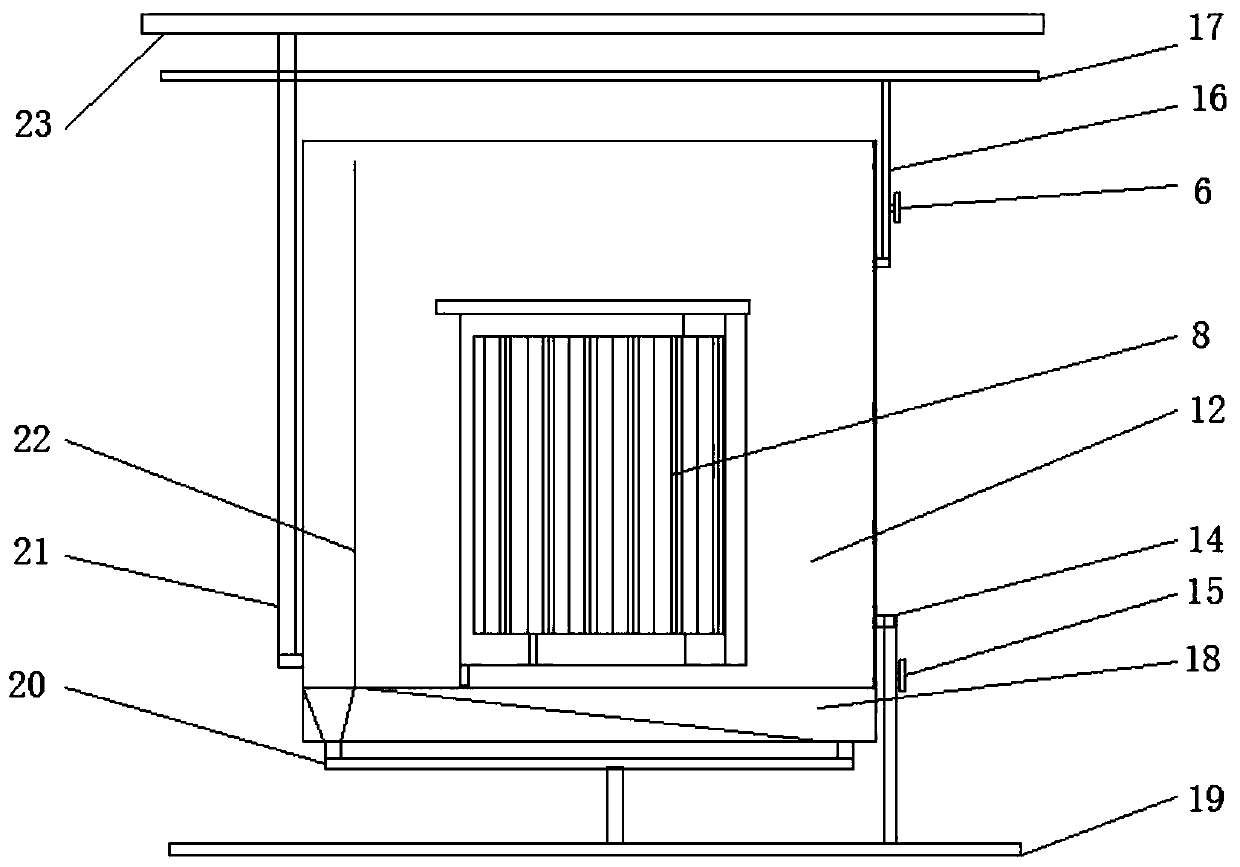

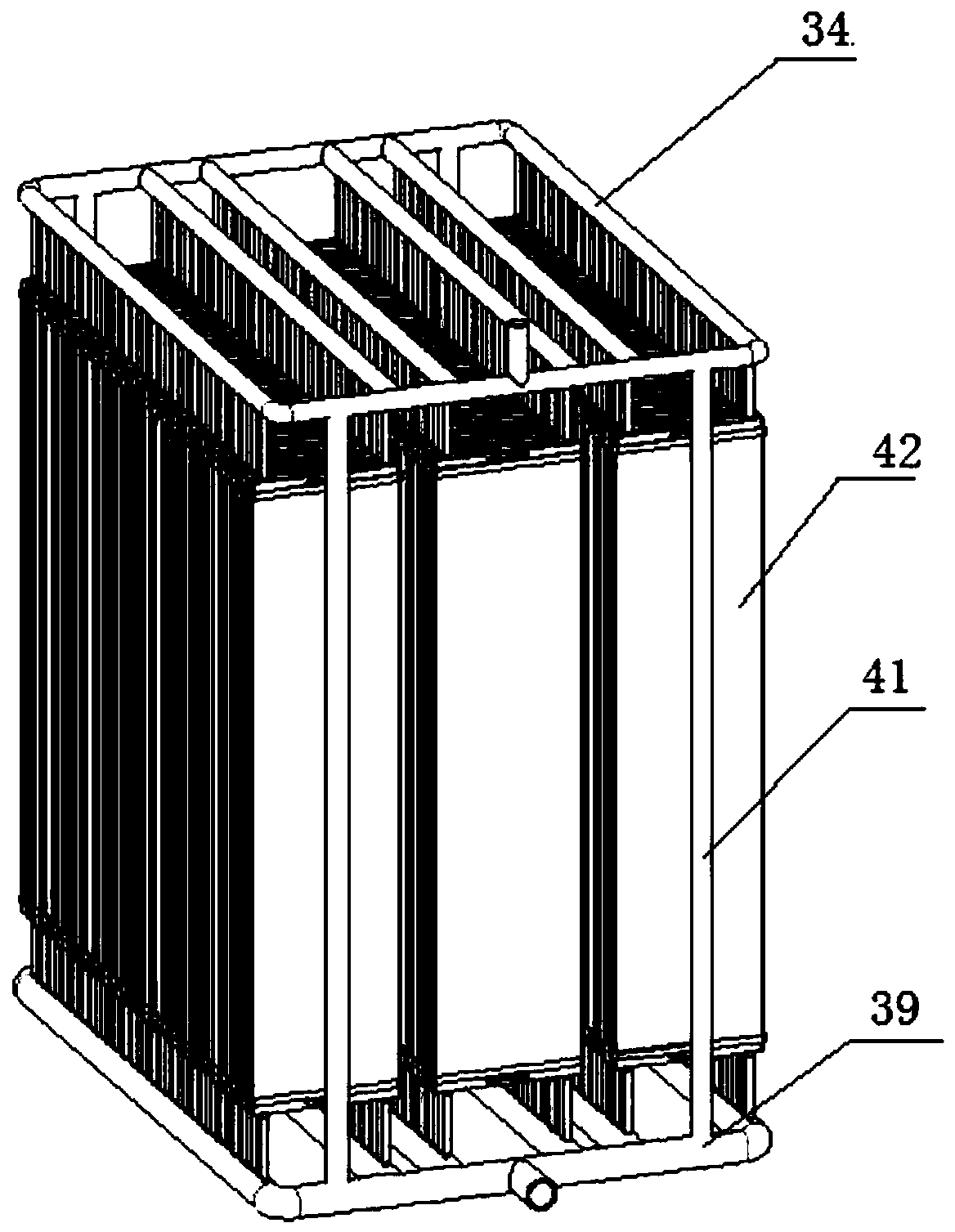

[0043] A kind of MBR water treatment system utilizing siphon to produce water, such as figure 1 , 2 As shown, it includes a biological treatment unit and a submerged membrane treatment unit. The biological treatment unit includes an anaerobic tank 1, an anoxic tank 3 and an aerobic tank 4. A stirring device 2 can be installed in the anaerobic tank 1 and anoxic tank 3. The submerged membrane processing unit includes a membrane box 12 and a group of submerged membrane stacks 8 installed in the membrane box 12. The submerged membrane stack 8 adopts a frameless full-channel filter membrane stack. The water inlets of the frameless full-channel filter membrane module are respectively connected to the main water inlet pipe 23 through the water inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com