A kind of preparation method of magnetic conductive bioceramic electrode for microbial fuel cell

A technology of fuel cells and bioceramics, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of lower conversion efficiency of battery systems, low ion exchange efficiency, and difficulty in biofilm formation, achieving short production time and good electrical conductivity , the effect of low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method for a magnetically conductive bioceramic electrode for a microbial fuel cell, comprising the following steps:

[0026] The first step is to prepare a porous ceramic plate: pour 30% of clay, 30% of quartz sand, 15% of fly ash, 5% of resin, and 20% of feldspar into the beaker by weight percentage, mix, granulate, and pass through 40 mesh Sieve, press molding at 20MPa, dry at 70°C, and fire at 1260°C to obtain porous ceramic plates;

[0027] The second step is to prepare the anode electrode: 2.5g graphite and 1.5g nano Fe 3 o 4 After mixing, add 12g of water glass solution with a mass concentration of 30% and stir to obtain a mixed coating, and then use a brush to coat the mixed coating on the porous ceramic plate prepared in the first step and then dry it at 70°C;

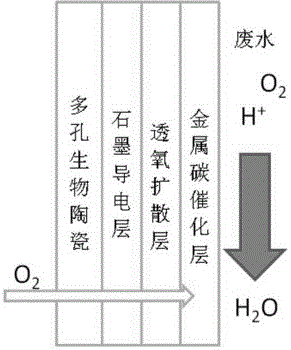

[0028] The third step is to prepare the cathode electrode: including the preparation of coating the carbon base layer, coating the diffusion layer, and coating the catalytic layer. The s...

Embodiment 2

[0033] A preparation method for a magnetically conductive bioceramic electrode for a microbial fuel cell, comprising the following steps:

[0034] The first step is to prepare a porous ceramic plate: pour 30% of clay, 30% of quartz sand, 15% of fly ash, 5% of resin, and 20% of feldspar into the beaker by weight percentage, mix, granulate, and pass through 40 mesh Sieve, press molding at 20MPa, dry at 70°C, and fire at 1280°C to obtain porous ceramic plates;

[0035] The second step is to prepare the anode electrode: 2.0g graphite and 1.2g nano Fe 3 o 4 After mixing, add 9.6g of water glass solution with a mass concentration of 30% and stir evenly to obtain a mixed coating, apply the mixed coating on the porous ceramic plate prepared in the first step with a brush, and then dry it at 70°C ;

[0036] The third step is to prepare the cathode electrode: including the preparation of coating the carbon base layer, coating the diffusion layer, and coating the catalytic layer. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com