Water dispersible granule seed coating formulation and preparation method thereof

A technology for dispersing granules and dispersants, applied in botany equipment and methods, insecticides, biocides, etc., can solve the problems of inability to prevent and control crop seedling diseases and insect pests at the same time, low seed coating rate, and easy shedding of seed coats, etc. problem, to achieve the effect of good suspension rate, good suspension, and firm coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

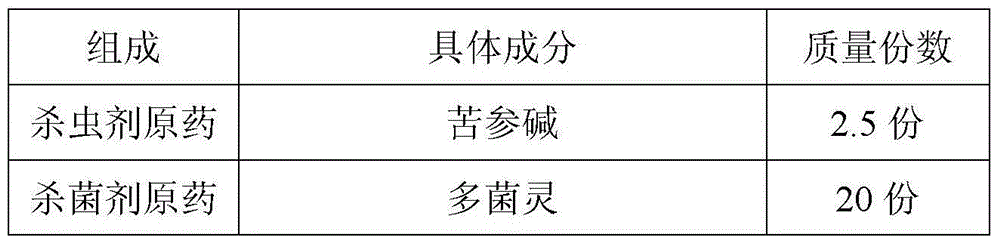

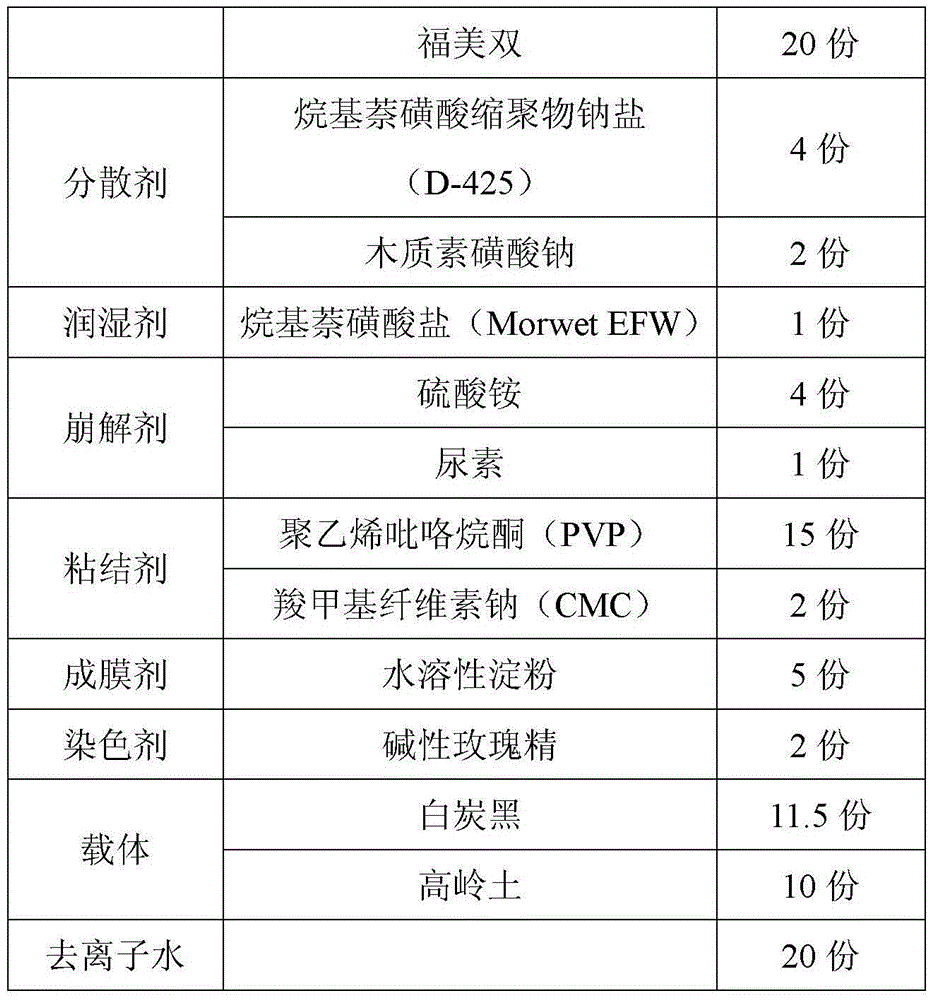

[0017] Specific embodiment one: the water-dispersible granular seed coating agent of the present embodiment consists of 5 to 40 parts of fungicides, 0 to 40 parts of insecticides, 4 to 8 parts of dispersants, 1 ~3 parts of wetting agent, 1~5 parts of disintegrating agent, 5~20 parts of film forming agent, 0.5~4 parts of dyeing agent and 0~40 parts of carrier; the fungicide original drug is fludioxonil , Indazole sulfasulfame, penconazole, carbendazim, thiram and tebuconazole or a combination of several of them, and the original insecticide is chlorpyrifos and / or matrine.

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the described dispersant is sodium lignin sulfonate, alkyl naphthalene sulfonic acid polycondensate sodium salt (D-425), sodium n-butyl naphthalene sulfonate One of (MorwetB), sodium diisobutylnaphthalene sulfonate (pull-off powder BX) and sodium 1-methylnaphthalene sulfonate (MF) or a combination of several of them. Others are the same as in the first embodiment.

[0019] When the dispersant of this embodiment is a composition, each dispersant is combined in arbitrary ratios.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the wetting agent is alkyl naphthalene sulfonate (Morwet EFW), sulfosuccinate (Lankropol KPH70) and dodecyl One or a combination of sodium sulfate (SDS). Others are the same as in the first or second embodiment.

[0021] When the wetting agent of this embodiment is a composition, each wetting agent is combined in arbitrary ratios.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com