Device and method for active carbon flue gas desulphurization and production of dilute sulphuric acid

A technology of activated carbon and dilute sulfuric acid, applied in separation methods, chemical instruments and methods, sulfur compounds, etc., can solve the problems of large footprint, cumbersome operation, and high investment, and achieve flue gas desulfurization operations in continuous towers, high mass transfer Effect, effect of rapid desulfurization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

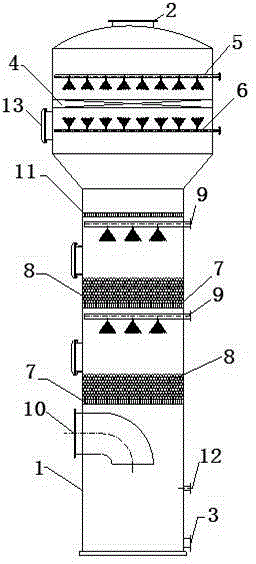

[0042] A device for activated carbon flue gas desulfurization and production of dilute sulfuric acid, which has two activated carbon absorption and elution devices, using spherical activated carbon with a diameter of 4-8mm or hollow spherical activated carbon with a diameter of 8-20mm as the desulfurizer; each layer of activated carbon in the filling layer The height of the static layer is 500mm, the height of the fluidized zone is 1000mm, the flow rate of the flue gas is 2.5~6m / s; the density of the spray liquid of the absorption liquid in the tower is 20~40m 3 / m 2 ·h; single-layer packed bed resistance 800~1500Pa; SO treatment 2 For flue gas whose concentration is less than 1%, the flue gas concentration at the tower outlet is ≤400mg / Nm 3 . Due to the severe turbulence and large wear in the fluidized area, the shape of the activated carbon is designed as a spherical shape with better fluidity. In order to maintain the desulfurization reaction temperature, the washing liqu...

Embodiment 2

[0044] Roasting flue gas (SO 2 Concentration 3%) After sulfuric acid is produced through the one-turn-one-suction process, the tail gas contains SO 2 Concentration up to 3000mg / Nm 3 , using this device to desulfurize flue gas and produce dilute sulfuric acid at the same time. The flue gas at 80°C enters the desulfurization tower, and there are two filling layers in the tower. Under the action of spherical activated carbon flue gas and spray liquid, it turbulently churns in the fluidization area. The sulfur dioxide in the flue gas is quickly absorbed, oxidized into sulfuric acid and then enters the Liquid phase spray liquid, the SO in the flue gas after the flue gas is desulfurized by two layers of activated carbon 2 Concentration down to 350mg / Nm 3, up to the emission standard. Sulfuric acid is continuously accumulated in the spray liquid, and when the concentration of dilute sulfuric acid reaches the specified concentration (according to user requirements, generally less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com