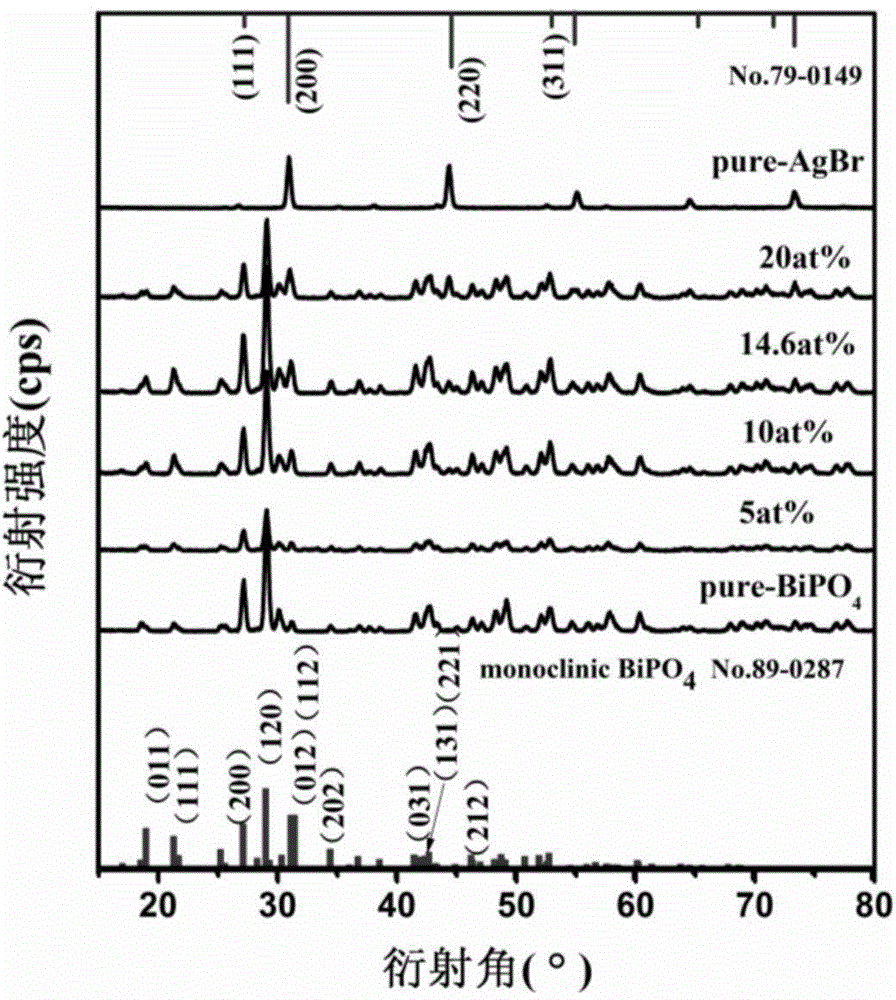

Composite silver bromide-bismuth phosphate heterojunction photocatalytic material and preparation method thereof

A composite photocatalysis and bismuth phosphate technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of easy decomposition, poor stability of silver bromide, and low photocatalytic activity of bismuth phosphate , to achieve the effects of simple preparation process, easy control of material shape and size, good stability and reusable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

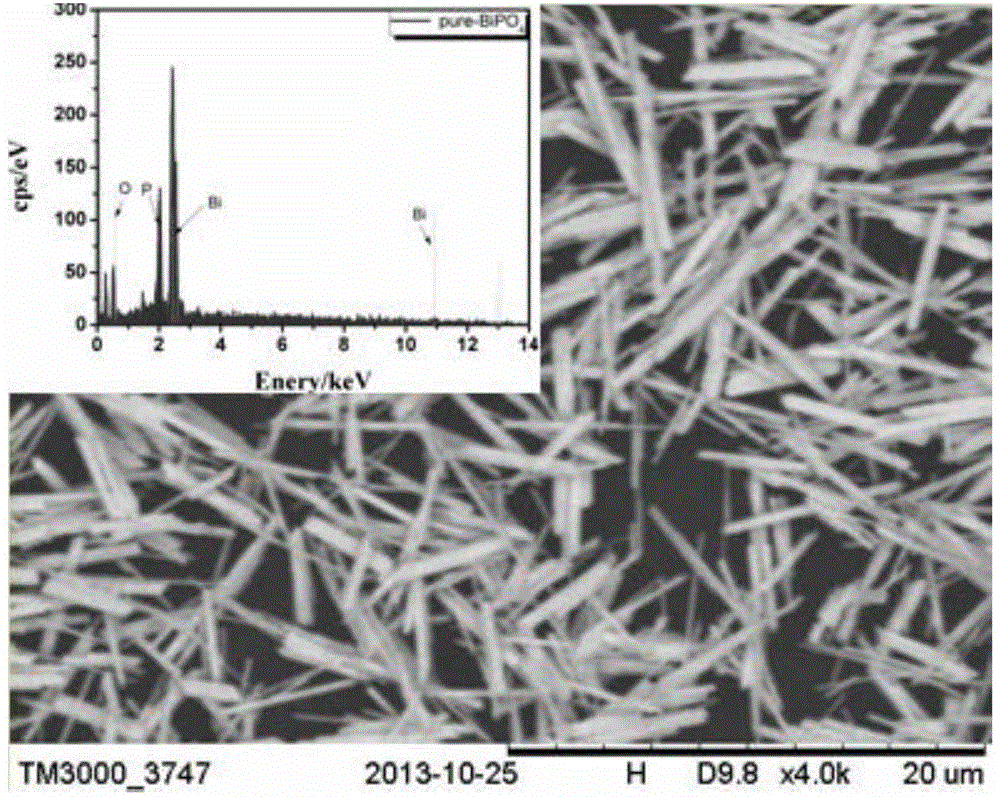

[0038] (1) prepare bismuth phosphate:

[0039] 5mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in 5 mL of dilute nitric acid solution with a concentration of 4 mol / L, magnetically stirred for 30 min until the bismuth nitrate was completely dissolved; 5 mmol of ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) was dissolved in 15mL deionized water, then added dropwise to the bismuth nitrate solution, and continued to stir for 2h. Transfer the reacted suspension to a Teflon-lined stainless steel reaction kettle, seal the kettle, and conduct a hydrothermal reaction at 190°C for 24 hours. After the reaction, naturally cool to room temperature, centrifuge, wash, and vacuum-dry at 80°C for 8 hours to obtain a white Powder BiPO 4 .

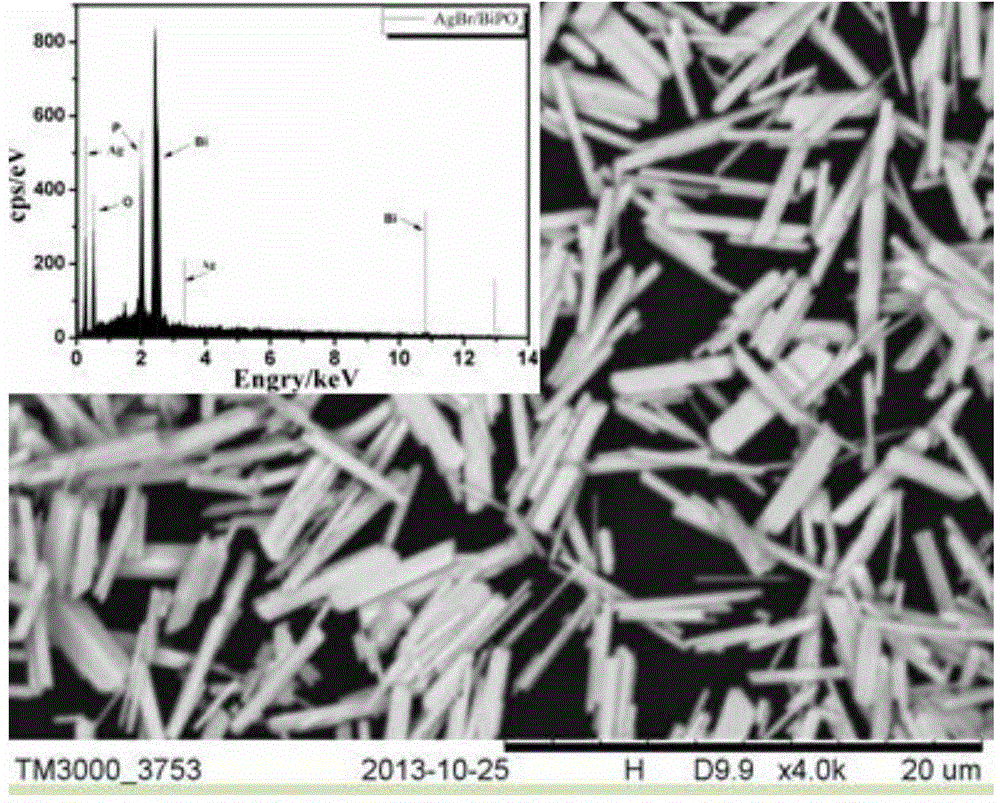

[0040] (2) Preparation of silver bromide-bismuth phosphate heterojunction composite photocatalytic material:

[0041] 0.8494g of silver nitrate solid was dissolved in 10mL of deionized water, and then added dropwise with a concentration of 28%...

Embodiment 2

[0043] (1) prepare bismuth phosphate:

[0044] 5mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 0) be dissolved in 5mL, the concentration is in the dilute nitric acid solution of 4mol / L, magnetically stirred for 30min until the bismuth nitrate is completely dissolved; 5mmol ammonium dihydrogen phosphate is dissolved in 15mL deionized water, then added dropwise in the bismuth nitrate solution, continue Stir for 2h. Transfer the reacted suspension to a Teflon-lined stainless steel reaction kettle, seal the kettle, and conduct a hydrothermal reaction at 180°C for 30 hours. After the reaction, cool to room temperature naturally, centrifuge, wash, and vacuum-dry at 60°C for 12 hours to obtain a white Powder BiPO 4 .

[0045] (2) Preparation of silver bromide-bismuth phosphate heterojunction composite photocatalytic material:

[0046] 0.8494g of silver nitrate solid was dissolved in 10mL of deionized water, and then added dropwise with a concentration of 28% (mass percentage) ammonia ...

Embodiment 3

[0048] (1) prepare bismuth phosphate:

[0049] 5mmol bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 0) be dissolved in 5mL, the concentration is in the dilute nitric acid solution of 4mol / L, magnetically stirred for 30min until the bismuth nitrate is completely dissolved; 5mmol ammonium dihydrogen phosphate is dissolved in 15mL deionized water, then added dropwise in the bismuth nitrate solution, continue Stir for 2h. Move the reacted suspension into a Teflon-lined stainless steel reaction kettle, seal the kettle, and conduct a hydrothermal reaction at 200°C for 20 hours. After the reaction, cool to room temperature naturally, centrifuge, wash, and vacuum-dry at 70°C for 9 hours to obtain a white Powder BiPO 4 .

[0050] (2) Preparation of silver bromide-bismuth phosphate heterojunction composite photocatalytic material:

[0051] Dissolve 0.8494g of silver nitrate solid in 10mL of deionized water, then add dropwise the ammoniacal liquor of 28% (mass percentage) until the precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com