Pyrene-4,5,9,10-quadri-imine-(arylamine) palladium chloride and application thereof in Heck reaction

A reaction and catalyst technology, applied in the field of chemistry, can solve the problems that palladium black is difficult to recycle and reuse, palladium powder is difficult to separate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

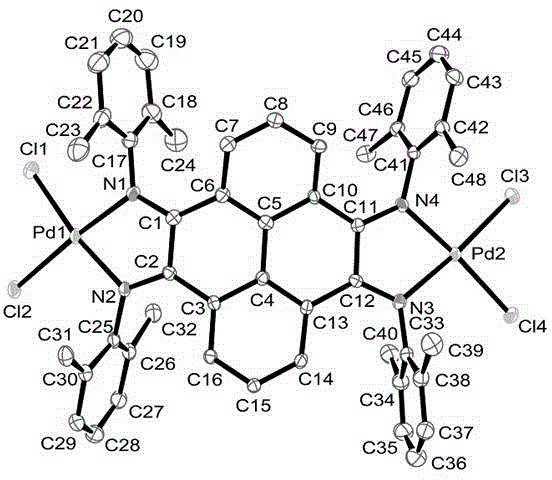

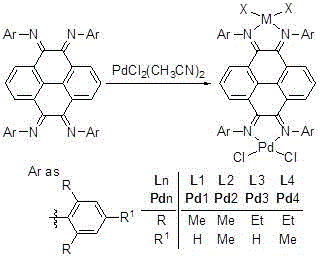

[0066] Synthetic method for preparing pyrene-4,5,9,10-tetraimine-(2,6-dimethylanilino)palladium(II) chloride [complex C1].

[0067]

[0068] 0.54 g (2.0 mmol) PdCl 2 (CH 3 EN) 2 Add 0.80 g (1.2 mmol) pyrene-4,5,9,10-tetraimine-(2,6-dimethylanilino) into a schlenk tube with 5 mL of dichloromethane, PdCl 2 (CH 3 EN) 2 The molar ratio to imine was 2.0:1.2, stirred at 30°C for 12 h, part of the dichloromethane was pumped out by a diaphragm pump, and 30 mL of diethyl ether was added, a reddish-brown solid precipitated, filtered through filter paper, and the filtrate was washed with diethyl ether (5 mL ×3), the washed solid was dried in a vacuum oven at 30 ℃ for 4 h to obtain 0.93 g of reddish-brown solid. Yield: 90.2%. 1 H NMR (400 MHz, CDCl 3 , ppm): 7.20 (d, J = 13.2 Hz, 4H, Ph- H ), 7.08 (d, J = 12.8 Hz, 6H, Ph- H ), 6.70-6.90 (m, 8H, Ph- H ), 2.32 (s, 6H, 2×C H 3 ), 2.18 (s, 6H, 2×C H 3 ), 1.91 (s, 6H, 2×C H 3 ), 1.32 (s, 6H, 2×C H 3 ).

[0069] 13 C...

Embodiment 2

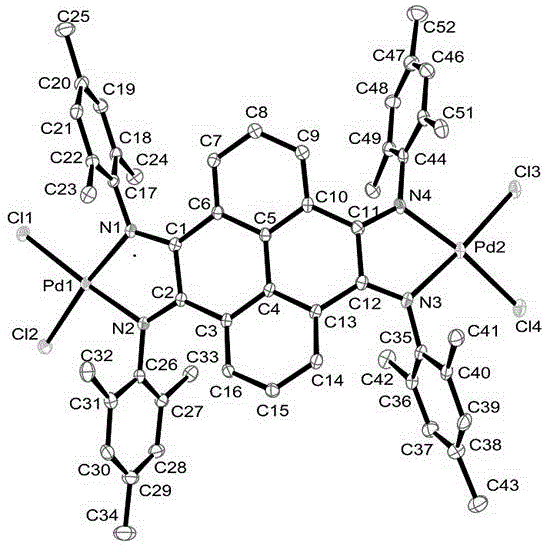

[0071] Synthetic method for preparing pyrene-4,5,9,10-tetraimine-(2,6-diethylanilino)palladium(II) chloride [complex C2].

[0072]

[0073] 0.54 g (2.0 mmol) PdCl 2 (CH 3 EN)2 Add to 0.93 g (1.2 mmol) pyrene-4,5,9,10-tetraimine-(2,6-diethylanilino) into a schlenk tube with 5 mL of dichloromethane, PdCl 2 (CH 3 EN) 2 The molar ratio to imine was 2.0:1.2, stirred at 30°C for 12 h, part of the dichloromethane was pumped out by a diaphragm pump, and 30 mL of diethyl ether was added, a reddish-brown solid precipitated, filtered through filter paper, and the filtrate was washed with diethyl ether (5 mL ×3), the washed solid was dried in a vacuum oven at 30 ℃ for 4 h to obtain 0.68 g of reddish-brown solid. Yield: 59.6%.

Embodiment 3

[0075] Synthetic method for preparing pyrene-4,5,9,10-tetraimine-(2,4,6-trimethylanilino)palladium(II) chloride [complex C3].

[0076]

[0077] 0.54 g (2.0 mmol) PdCl 2 (CH 3 EN) 2 Add 0.87 g (1.2 mmol) pyrene-4,5,9,10-tetraimine-(2,4,6-trimethylanilino) to a schlenk tube with 5 mL of dichloromethane, PdCl 2 (CH 3 EN) 2 The molar ratio to imine was 2.0:1.2, stirred at 30°C for 12 h, part of the dichloromethane was pumped out by a diaphragm pump, and 30 mL of diethyl ether was added, a reddish-brown solid precipitated, filtered through filter paper, and the filtrate was washed with diethyl ether (5 mL ×3), the washed solid was dried in a vacuum oven at 30 °C for 4 h to obtain 0.90 g of reddish-brown solid. Yield: 83.3%.

[0078] 1 H NMR (400 MHz, CDCl 3 , ppm): 7.05 (s, 4H, Ph- H ), 6.97-7.01 (m, 4H, Ph- H ), 6.76-6.80 (m, 3H, Ph- H ), 6.53-6.69 (m, 3H, Ph- H ), 2.38 (s, 6H, 2×C H 3 ), 2.19-2.37 (m, 24H, 8×C H 3 ), 1.30 (s, 6H, 2×C H 3 ). 13 C NMR (100 MHz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com