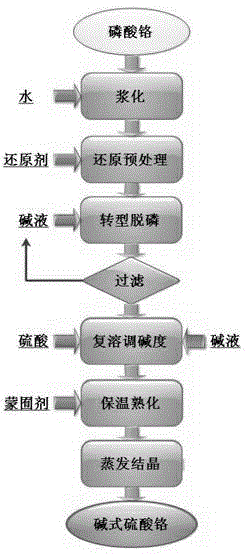

Method for preparation of basic chromium sulfate from chromium phosphate

A technology of chromium sulfate and chromium phosphate, applied in the direction of chromium sulfate, etc., can solve the problems of no large-scale industrial application and no invention patent, etc., and achieve the effects of significant economic benefits, low cost, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Choose chromium phosphate made by extracting chromium from electroplating sludge as raw material. In a closed reaction vessel, add water to liquid to solid ratio to 3:1 (L / kg), while adding 5% sodium sulfite to maintain a reducing atmosphere to prevent Cr 3+ It is oxidized and stirred into slurry. Add NaOH lye with an initial concentration of 80g / L into a closed container, adjust the liquid-to-solid ratio to 20:1 (L / kg), control the linear stirring speed at 100 m / min, heat to 50°C, and react for 180 minutes. After filtration, an intermediate product of chromium hydroxide is obtained. The removal rate of phosphate is 93.6%. The lye contains 66g / L of NaOH, which can be recycled. The chromium hydroxide was reconstituted with 2M sulfuric acid, and kept at 80 ℃ and the linear speed of stirring was controlled at 200 m / min for 10 minutes. The pH value of the solution was adjusted to 4 with NaOH alkali. After aging for 30 minutes, the obtained basic chromium sulfate solution was ...

Embodiment 2

[0044] Choose chromium phosphate made by extracting chromium from phosphorus chromium slag as raw material. In a closed reaction vessel, add water to liquid-solid ratio to 2:1 (L / kg), and add sodium thiosulfate at a concentration of 5% to prevent reducing atmosphere. Cr 3+ It is oxidized and stirred into slurry. Add NaOH lye with an initial concentration of 250g / L into a closed container, adjust the liquid-to-solid ratio to 5:1 (L / kg), control the linear stirring speed at 400 m / min, heat to 90°C, and react for 120 minutes. After filtration, an intermediate product of chromium hydroxide is obtained. The removal rate of phosphate is 94.1%. The lye contains 222g / L NaOH, which can be recycled. The chromium hydroxide was reconstituted with 2M sulfuric acid, and kept at 80 ℃ and the linear speed of stirring was controlled at 100 m / min for 10 minutes. The pH value of the solution was adjusted to 3.5 with NaOH alkali. After aging for 30 minutes, the obtained basic chromium sulfate solu...

Embodiment 3

[0046] Choose chromium phosphate made by extracting chromium from electroplating sludge as raw material. In a pressurized closed reaction vessel, add water to liquid-solid ratio to adjust to 3:1 (L / kg), while adding 3% sodium sulfite to maintain a reducing atmosphere to prevent Cr 3+ It is oxidized and stirred into slurry. Add NaOH lye with an initial concentration of 100g / L into a closed container, adjust the liquid-to-solid ratio to 10:1 (L / kg), control the linear stirring speed at 100 m / min, heat to 180°C, and react for 60 minutes. After filtration, an intermediate product of chromium hydroxide is obtained. The removal rate of phosphate is 95.1%. The lye contains 78g / L of NaOH, which can be recycled. The chromium hydroxide was reconstituted with 2M sulfuric acid, and kept at 80 ℃ and the linear speed of stirring was controlled at 200 m / min for 10 minutes. The pH value of the solution was adjusted to 3.5 with NaOH alkali. After aging for 30 minutes, the obtained basic chromium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com