A large-scale pig farm wastewater advanced treatment system

A technology for advanced treatment and pig farms, which is applied in the fields of animal husbandry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problem of unsatisfactory phosphorus removal effect and difficulty in reaching Class I discharge. Standards and other issues to achieve the effect of maximizing resource utilization, improving effects, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

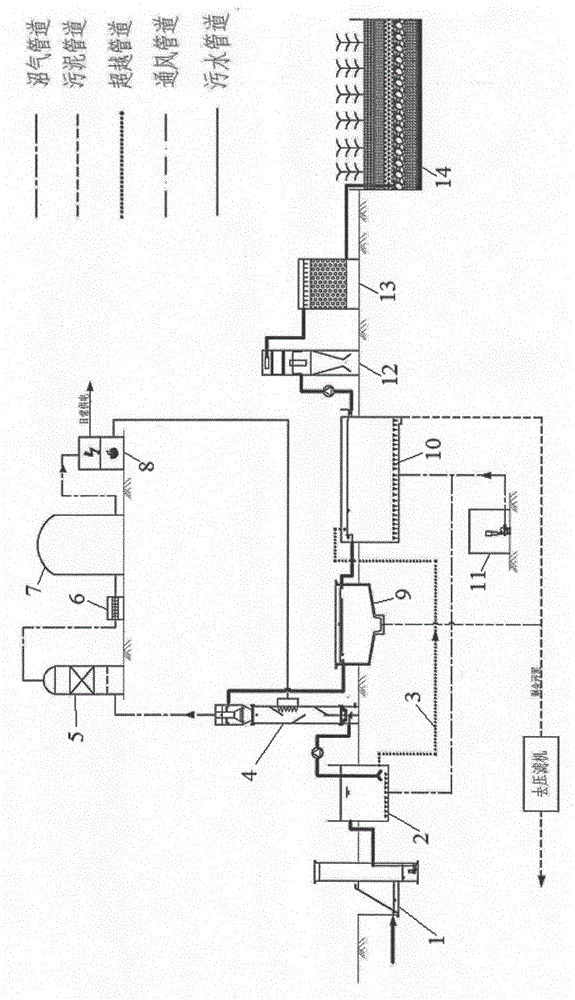

[0026] figure 1 It is a schematic diagram of a large-scale pig farm wastewater advanced treatment system provided by the present invention. The large-scale pig farm wastewater advanced treatment system is divided into a pretreatment part, a biochemical treatment part and an advanced treatment part.

[0027] The pretreatment part includes a grid well 1 and a hydrolytic acidification tank 2, and the outlet pipe of the grid well 1 is connected with the water inlet pipe of the hydrolytic acidification tank 2 through a lift pump. The hydrolytic acidification tank 2 is equipped with a microporous aeration tube, and the aeration volume is 1.5-3m 3 / (m 2 min).

[0028] The biochemical treatment part includes transcending tube 3, spiral symmetrical flow anaerobic reactor 4, one-piece sulfur-containing waste gas purification device 5, de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com