Ultra-thin resin foamed sheet as well as production method and application thereof

A foamed sheet material and a manufacturing method technology, which can be applied to other household appliances, applications, household appliances, etc., and can solve the problems of inability to meet the requirements of electronic products, poor sealing and cushioning properties, and large specific gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

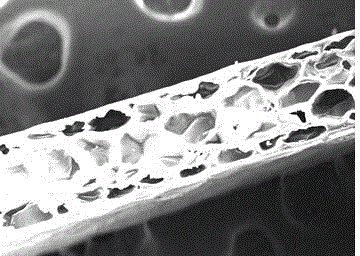

[0037] An ultra-thin resin foam sheet, LDPE (melting temperature 95°C, MFR value 2.0g / min, Daqing Petrochemical 18D) and EAA (melting temperature 126°C, MFR value 6.0g / min, Dow 3150) As the basic resin, ethylene-propylene rubber (softening temperature 150°C, 3722P) is added as modified rubber; the total amount of resin is 100 parts by weight, of which LDPE accounts for 30 parts by weight, EAA accounts for 30 parts by weight, and the amount of modified rubber added is 40 parts by weight share.

[0038] In the above 100 parts by weight resin, add 4 parts by weight of blowing agent amine azodicarbonate, add 2.5 parts by weight of antioxidant 1010, 1.5 parts by weight of sensitizer zinc stearate, 4 parts by weight of lubricating Agent stearic acid, the pigment of 7 parts by weight.

[0039] The manufacturing method of the ultra-thin resin foam sheet, the specific steps are:

[0040] (1) The above raw materials are mixed and granulated, and the mixing and granulation is divided i...

Embodiment 2

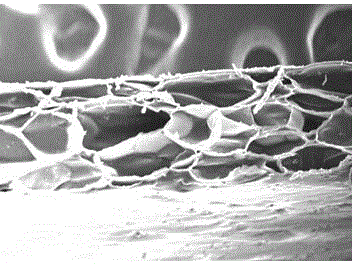

[0047] The difference from Example 1 is that in order to produce a thinner foam, the thermoplastic elastomer used is a polymer whose hard phase is formed through the combination of metal ions to form crosslinking points, and the soft phase is mainly made of PE non-crystalline polymer. Due to the better fluidity of this type of elastomer, it is suitable for thinner foam substrates, and has a great improvement in tensile strength and elongation at break. Corresponding to 100 parts by weight of resin (LDPE:EAA:elastomer=3:2:5), the amount of blowing agent added is 2 parts by weight.

[0048] In order to obtain a thinner foam substrate, in the extruding process part, the opening of the selected T-shaped die is 0.15. And when extrusion is required, the sheet is heated and stretched on both sides, the heating temperature is 60-80°C, the longitudinal stretch ratio is 3.6, and the transverse stretch ratio is 2.0. The obtained foam substrate has a thickness of 0.12±0.005mm. Using the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com