Preparation method of microwave absorbing material taking MOFs molecular structure as template

A microwave-absorbing material and molecular structure technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as high equipment requirements, complicated methods, and high production costs, and achieve simple follow-up processing, simple preparation processes, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing microwave absorbing material using MOFs molecular structure as a template includes the following steps:

[0028] Step 1. According to the previously reported methods (Lisong Xiao, Jiangtian Li, Dermot F. Brougham, Eoin K. Fox, Neus Feliu, Alexey Bushmelev, Annette Schmidt, Natascha Mertens, Fabian Kiessling, Martin Valldor, Bengt Fadeel, and Sanjay Mathur. Water-Soluble Superparamagnetic Magnetite Nanoparticles with Biocompatible Coating for Enhanced Magnetic Resonance Imaging. ACSNANO, 2011, 5, 6315-6324) Hydrothermal synthesis of 1~5 nm water-soluble Fe 3 O 4 Nano particles, Fe 3 O 4 Nano particles are dispersed in 10ml methanol solution for use, Fe 3 O 4 Fe in methanol solution 3 O 4 The concentration is 20mg / ml;

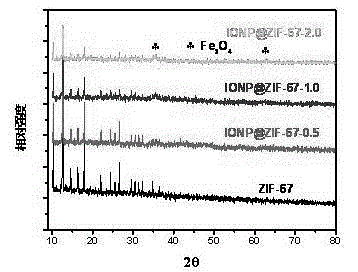

[0029] Step 2. Disperse 2.63 g of 2-methylimidazole and 0.5 mL of the step 1 solution in 40 ml of methanol solution ultrasonically, and mark the resulting solution as A solution; at the same time, 500 mg of CoCl 2 Dissolve 600mg of polyvin...

Embodiment 2

[0033] Step 1. According to the previously reported methods (Lisong Xiao, Jiangtian Li, Dermot F. Brougham, Eoin K. Fox, Neus Feliu, Alexey Bushmelev, Annette Schmidt, Natascha Mertens, Fabian Kiessling, Martin Valldor, Bengt Fadeel, and Sanjay Mathur. Water-Soluble Superparamagnetic Magnetite Nanoparticles with Biocompatible Coating for Enhanced Magnetic Resonance Imaging. ACSNANO, 2011, 5, 6315-6324) Hydrothermal synthesis of 1~5 nm water-soluble Fe 3 O 4 Nano particles, Fe 3 O 4 Nano particles are dispersed in 10ml methanol solution for use, Fe 3 O 4 Fe in methanol solution 3 O 4 The concentration is 23mg / ml;

[0034] Step 2. Disperse 2.63 g of 2-methylimidazole and 1 mL of the solution of step 1 ultrasonically in 40 ml of methanol solution, and mark the resulting solution as A solution; at the same time, 500 mg of CoCl 2 Dissolve 600mg of polyvinylpyrrolidone K30 in 40ml methanol solution, and mark the obtained solution as B solution;

[0035] Step 3. Under mechanical stirring, ...

Embodiment 3

[0038] Step 1, same as embodiment 1;

[0039] Step 2. Disperse 2.63 g of 2-methylimidazole and 2 mL of the solution of step 1 in 40 ml of methanol solution ultrasonically, label the resulting solution as A solution; at the same time, 500 mg of CoCl 2 Dissolve 600mg of polyvinylpyrrolidone K30 in 40ml methanol solution, and mark the obtained solution as B solution;

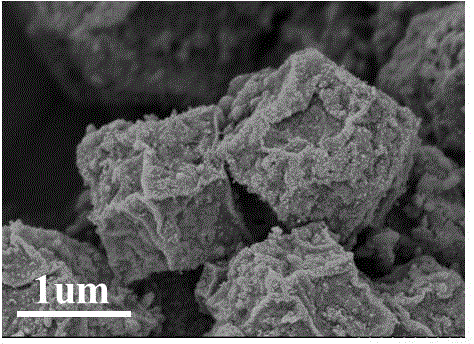

[0040] Step 3. Under mechanical stirring, add liquid B from step 2 to liquid A drop by drop. After the two solutions are mixed, continue to stir for 4 hours, then leave the mixed solution to stand and age for 24 hours, and finally magnetically separate the solution , Get a solid powder, mark the solid powder as Fe 3 O 4 ZIF-67-2;

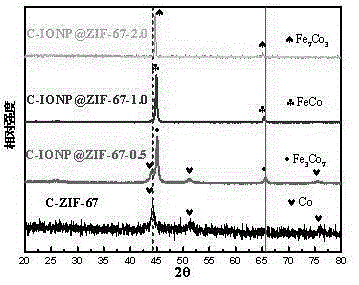

[0041] Step 4. Calcining the solid powder of step 3 in a nitrogen atmosphere for 1 hour at a calcination temperature of 700°C, where the heating rate is 3°C / min, to obtain porous carbon-coated Fe X Co 1-x Alloy, label the product as C-Fe 3 O 4 ZIF-67-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com