Bored composite pile structure under karst cave/soil cave geological condition

A technology of geological conditions and composite piles, applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problem of large concrete filling coefficient, achieve the effect of reducing the amount, reducing the filling coefficient, and reducing the filling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

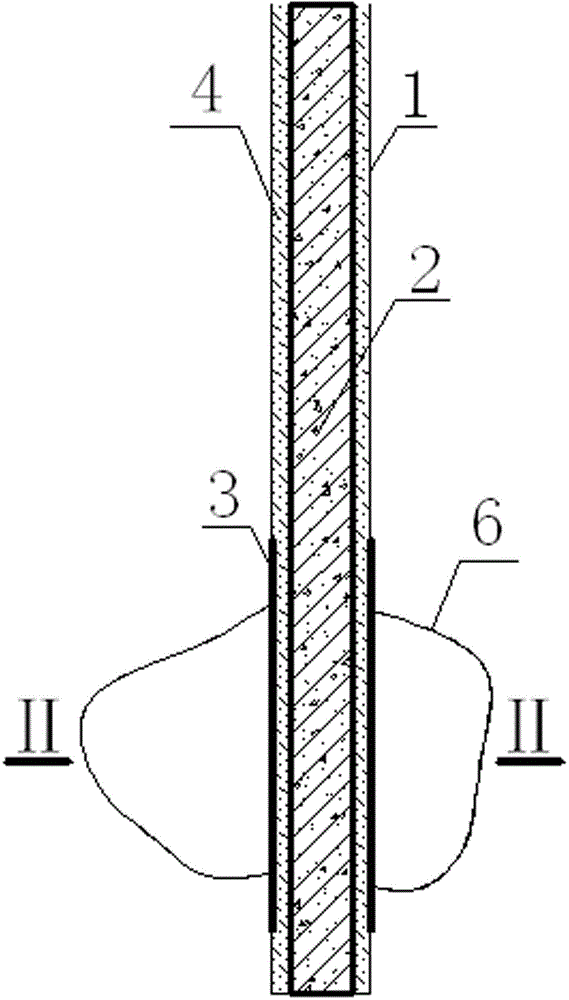

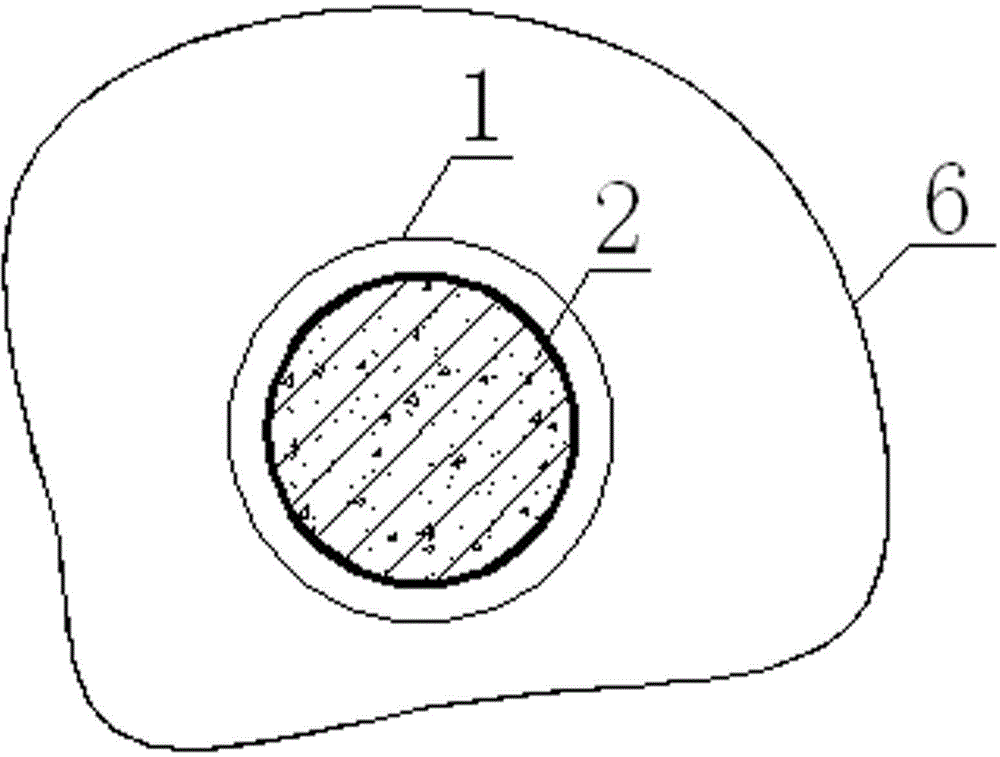

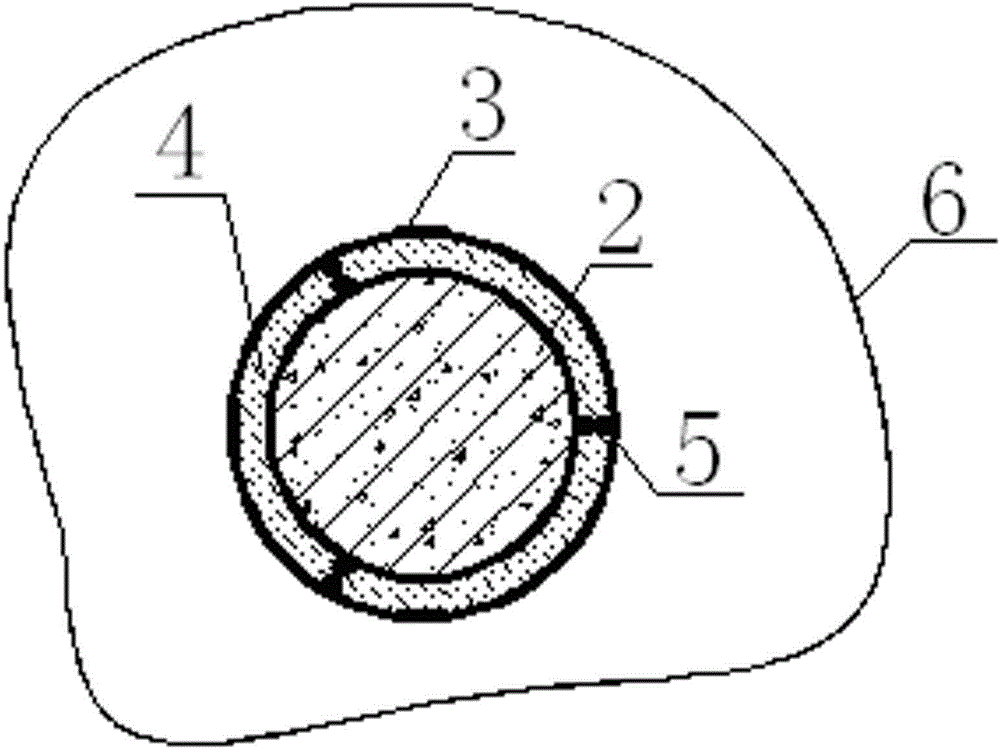

[0047] Example 1 :Such as figure 1 , 2 , 3, 4, and 5, prefabricate concrete square piles with a side length of 600mm at the construction site according to the bearing capacity requirements, and maintain them naturally. Cement, clay and water are used as raw materials to make clay cement slurry after mixing and filtering. Then drill a hole with a drilling machine, and the diameter of the hole is 200mm longer than the prefabricated pile side. After clearing the soil in the borehole, the prefabricated pile 2 is implanted into the borehole with a hoisting machine, and finally the clay cement slurry 4 is poured into the hole with a grouting pipe. Inject the gap between the reinforced concrete prefabricated pile and the borehole so that the side friction resistance of the prefabricated pile can be exerted. During operation, the center of the prefabricated pile should coincide with the center of the borehole to meet the design requirements.

Embodiment 2

[0048] Example 2 :Such as figure 1 , 2 , 3, 4, and 5, prefabricated prestressed concrete pipe piles with a diameter of 600mm and a wall thickness of 100mm were prefabricated at the construction site according to the design bearing capacity requirements, and naturally maintained. Then cement, clay and water are used as raw materials, and clay cement slurry is made after mixing and filtering according to national standards. Then use a drilling machine to form a hole. The diameter of the drilling hole is 200mm larger than that of the prefabricated pile. The gap between the piles can be used to make the side friction resistance of the pile body play a role. The center of the prefabricated pile should coincide with the center of the borehole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com