Method for preparing zinc oxide/epoxy resin composite voltage dependent resistor

A varistor, epoxy resin technology, applied in resistance manufacturing, resistors, circuits, etc., can solve the problems of ineffective contact of microspheres, difficult preparation and molding process, poor mechanical properties, etc., to reduce the preparation cost and easy to operate. , The effect of convenient insulation design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

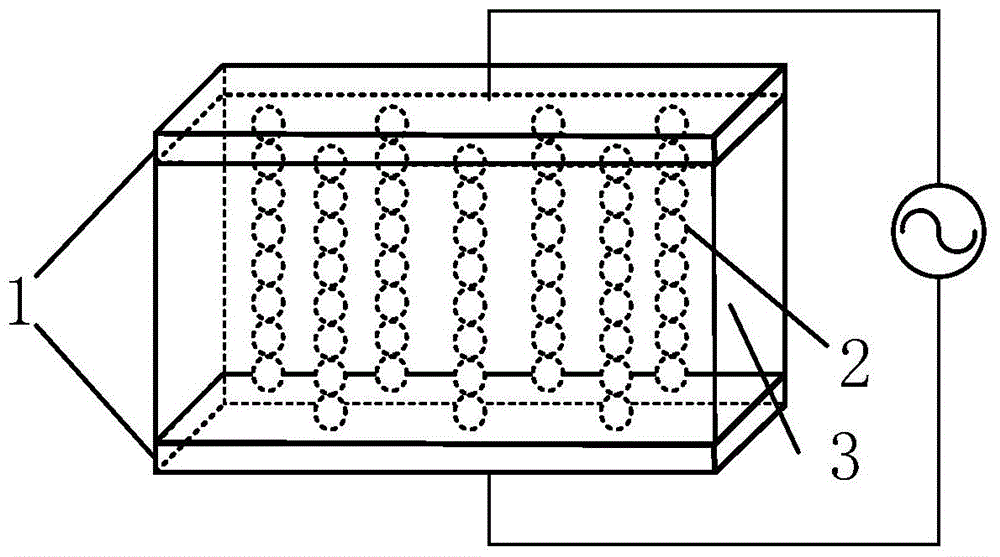

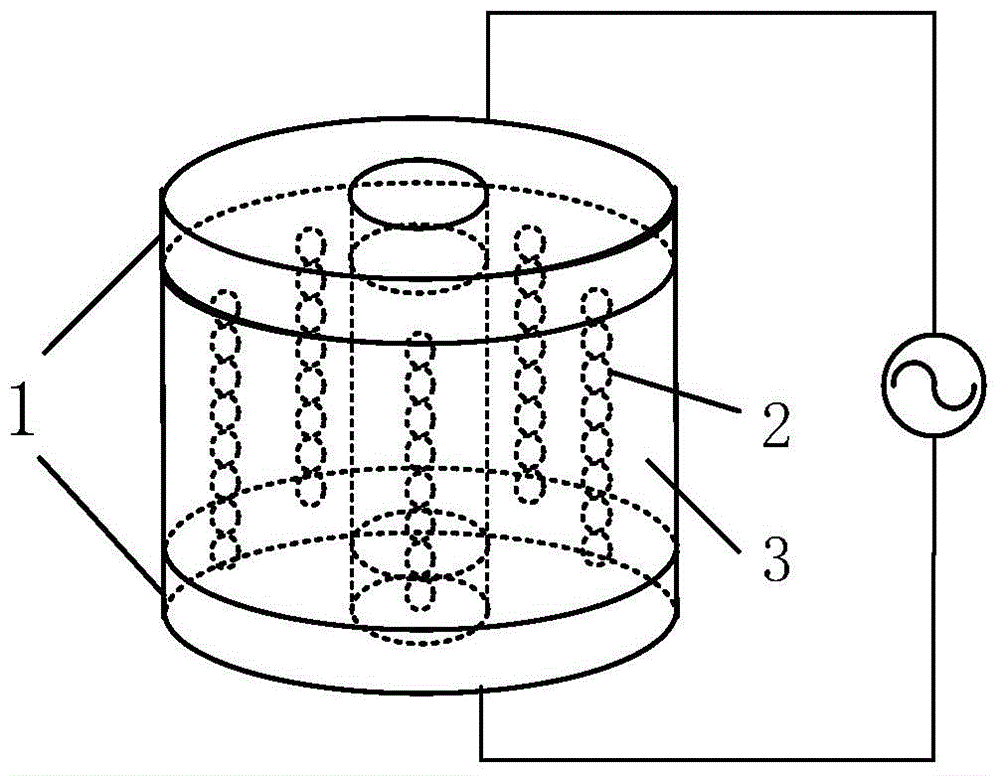

[0020] The preparation method of zinc oxide / epoxy resin composite varistor that the present invention proposes comprises the following steps:

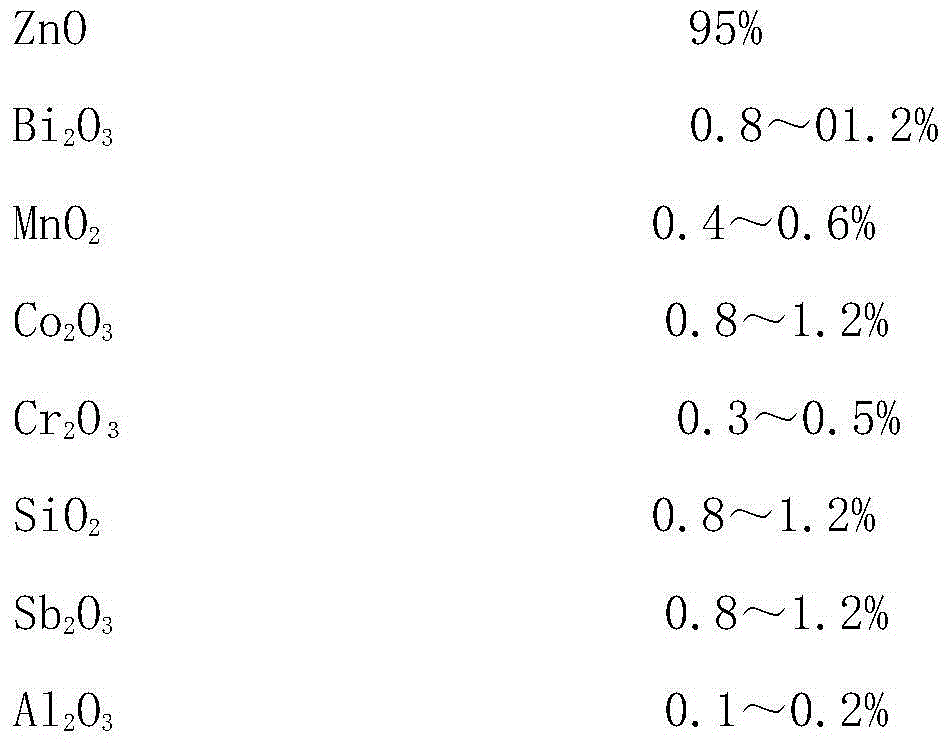

[0021] (1) Weigh the raw materials according to the following mole percentages:

[0022]

[0023] mixing the above measured raw materials and then ball milling to obtain the first mixture with a particle size of 1-20 microns;

[0024] (2) granulating the above mixture by spray granulation to obtain microspheres with a diameter of 50 to 150 microns;

[0025] (3) The above-mentioned microspheres are heated to 1200°C at a rate of 0.55°C / min and sintered for 4.5 hours, and then cooled to room temperature at a rate of 1.6°C / min, and the sintered microspheres are sieved to obtain particles with a particle size of 100-125 microns. Varistor microspheres;

[0026] (4) Taking epoxy resin as the matrix, adding the above-mentioned piezoresistor microspheres in the matrix, the mass percentage added is: matrix: piezoresistor microspheres=3:(0.6...

Embodiment 1

[0030] (1) Weigh the raw materials according to the following mole percentages:

[0031]

[0032] mixing the above measured raw materials and then ball milling to obtain the first mixture with a particle size of 1-20 microns;

[0033] (2) granulating the above mixture by spray granulation to obtain microspheres with a diameter of 50 to 150 microns;

[0034] (3) The above-mentioned microspheres are heated to 1200°C at a rate of 0.55°C / min and sintered for 4.5 hours, and then cooled to room temperature at a rate of 1.6°C / min, and the sintered microspheres are sieved to obtain particles with a particle size of 100-125 microns. Varistor microspheres;

[0035] (4) Take epoxy resin as matrix, add above-mentioned varistor microsphere in matrix, the mass percent of adding is: matrix: varistor microsphere=3:0.8, obtains the second mixture, wherein said matrix is Room temperature curing epoxy resin composed of component A and component B, blended at room temperature for 5 minutes, ...

Embodiment 2

[0038] (1) Weigh the raw materials according to the following mole percentages:

[0039]

[0040] mixing the above measured raw materials and then ball milling to obtain the first mixture with a particle size of 1-20 microns;

[0041] (2) granulating the above mixture by spray granulation to obtain microspheres with a diameter of 50 to 150 microns;

[0042](3) The above-mentioned microspheres are heated to 1200°C at a rate of 0.55°C / min and sintered for 4.5 hours, and then cooled to room temperature at a rate of 1.6°C / min, and the sintered microspheres are sieved to obtain particles with a particle size of 100-125 microns. Varistor microspheres;

[0043] (4) Take epoxy resin as matrix, add above-mentioned varistor microsphere in matrix, the mass percent of adding is: matrix: varistor microsphere=3:1.2, obtains the second mixture, wherein said matrix is The room temperature curing epoxy resin composed of component A and component B is blended at room temperature for 5 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com