Preparation method of GaN-based LED epitaxial structure

An epitaxial structure, N-type technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency and uneven electron distribution of GaN-based light-emitting epitaxial structures, and achieve enhanced internal quantum efficiency, uniform distribution, and improved Effect of Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

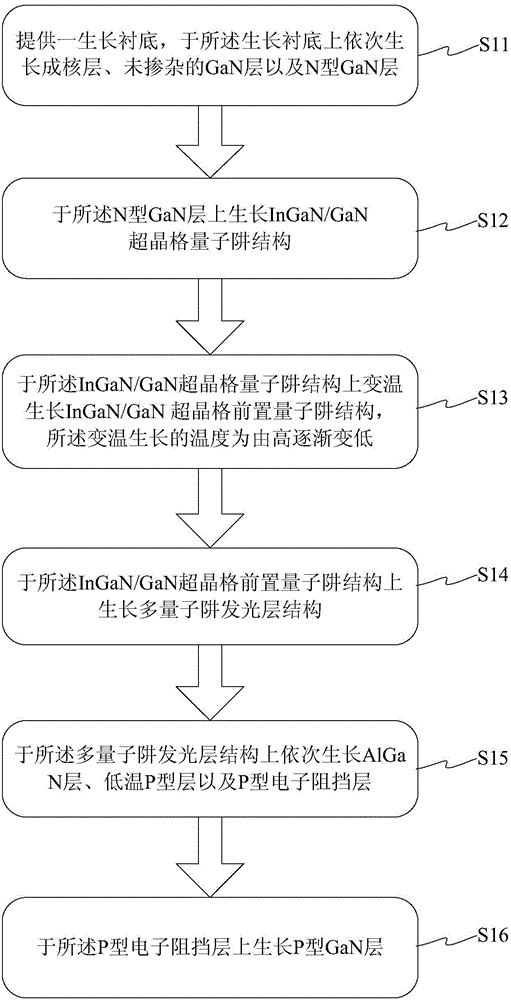

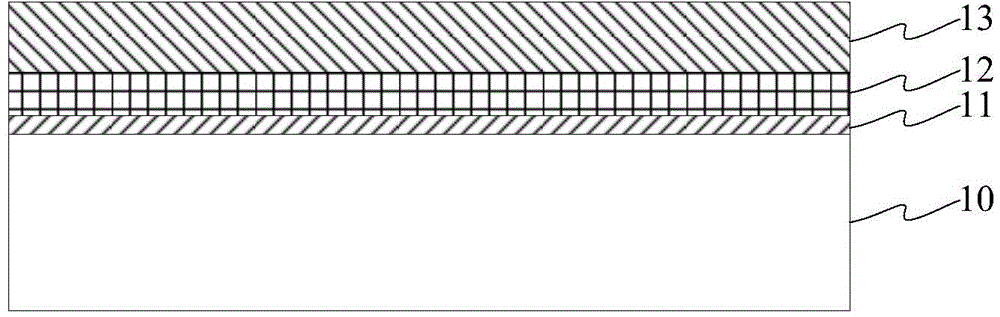

[0056] Such as Figure 1 to Figure 7 As shown, this embodiment provides a method for preparing a GaN-based LED epitaxial structure, and the preparation method includes steps:

[0057] Such as figure 1 and figure 2 As shown, step 1) S11 is first performed to provide a growth substrate 10 on which a nucleation layer 11 , an undoped GaN layer 12 and an N-type GaN layer 13 are sequentially grown.

[0058] As an example, the growth substrate 10 may be sapphire, GaN, silicon, silicon carbide, etc. In this embodiment, the growth substrate 10 is a sapphire substrate.

[0059] Specifically, this step includes the following sub-steps:

[0060] In step 1-1), a sapphire substrate is provided, and a nucleation layer 11 is grown on the surface of the sapphire substrate at a temperature of 450-650° C., and the growth thickness of the nucleation layer 11 is in the range of 15-50 nm.

[0061] Step 1-2), growing an undoped GaN layer 12 on the surface of the nucleation layer 11 at a tempera...

Embodiment 2

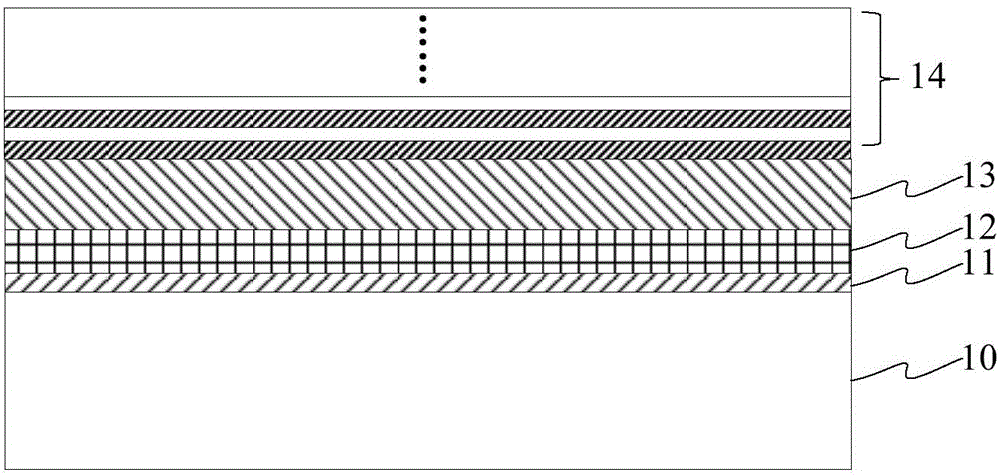

[0087] Such as Figure 7 As shown, this embodiment provides a GaN-based LED epitaxial structure, and the GaN-based LED epitaxial structure includes a nucleation layer 11, an undoped GaN layer 12, an N-type GaN layer 13, and an InGaN / GaN supercrystalline layer stacked in sequence. Lattice quantum well structure 14, InGaN / GaN pre-quantum well structure 15 grown gradually from high temperature to low temperature, multi-quantum well light-emitting layer structure 16, AlGaN layer 17, low-temperature P-type layer 18, P-type electron blocking layer 19, and P-type GaN layer 20 .

[0088] Such as Figure 7 As shown, the GaN-based LED epitaxial structure is formed on a growth substrate 10 including one of sapphire, GaN, silicon and silicon carbide. In this embodiment, the GaN-based LED epitaxial structure is formed on a sapphire substrate.

[0089] The thickness range of the nucleation layer 11 is 15-50nm; the total thickness range of the undoped GaN layer 12 and the N-type GaN layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com