Simple surface modification method of Li-rich cathode material

A lithium-rich cathode material and surface modification technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of high precipitation speed control requirements, low first cycle Coulomb efficiency, and unsatisfactory cycle performance. Achieve the effect of improving interface stability, simplifying process flow, improving rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

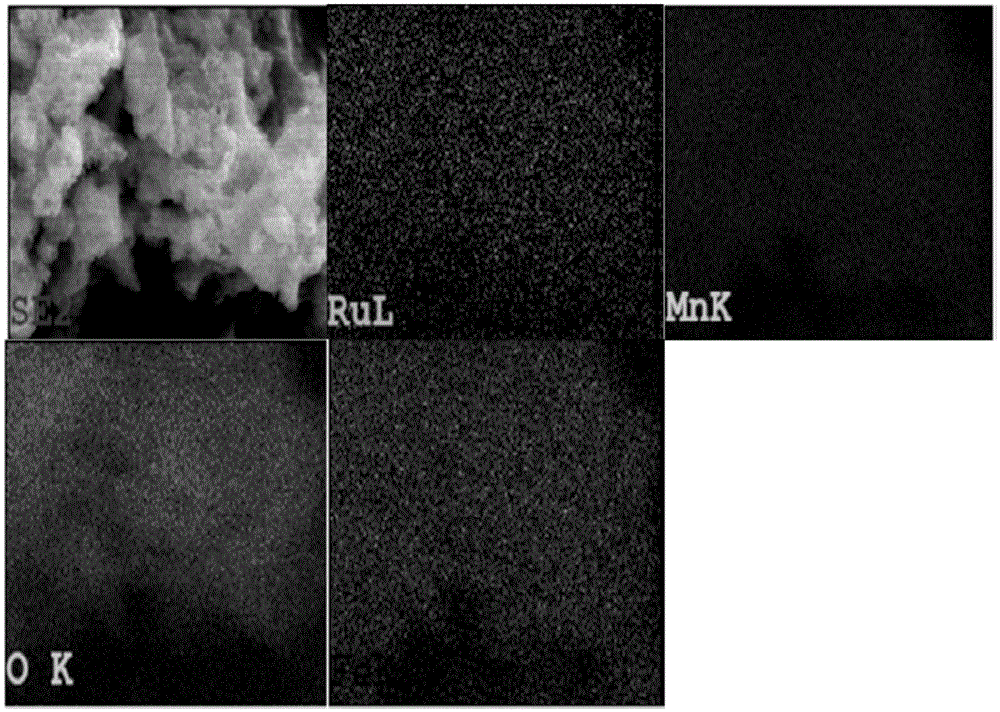

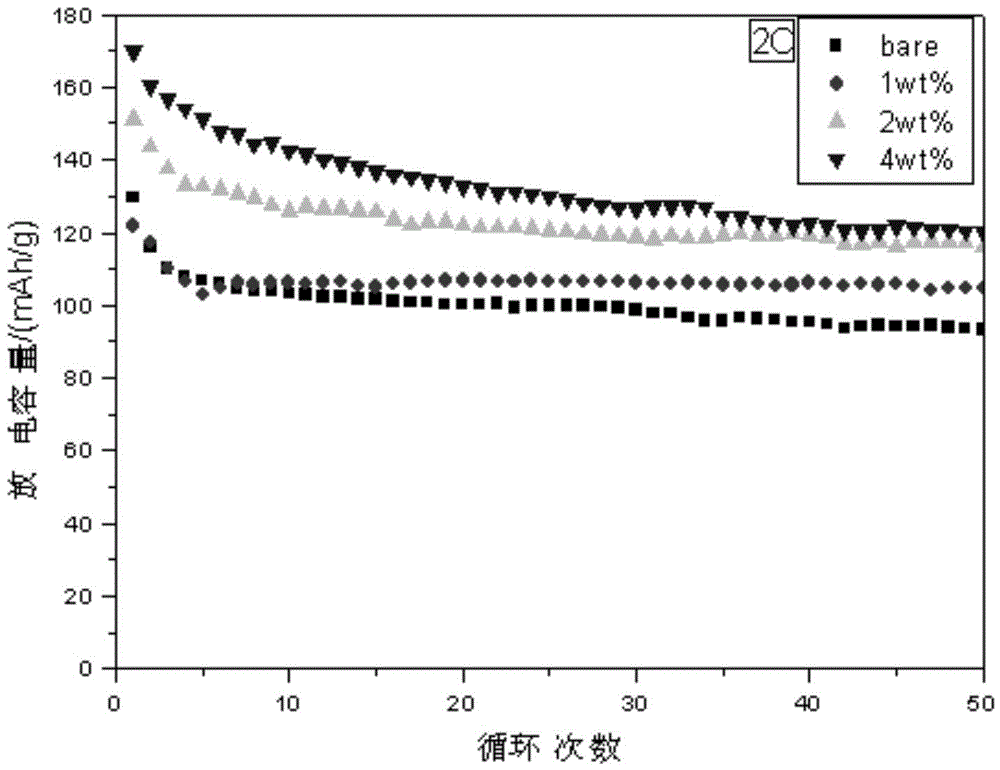

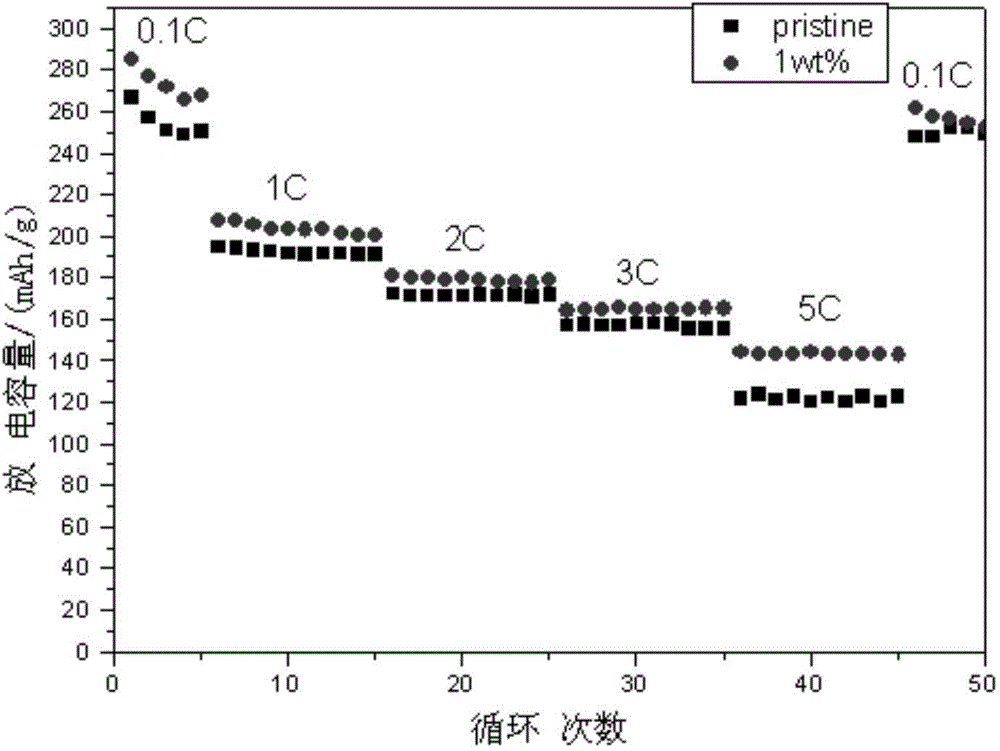

[0028] Weigh the composition as 0.7Li 2 MnO 3 ·0.3LiFeO 2 Add 5.000 g of lithium-rich positive electrode material to a mixed solution of deionized water and ethanol (ethanol and deionized water, 100 mL each), and ultrasonically disperse for 0.5 h. 0.0976g RuCl 3 ·XH 2 O (with RuO 2 The solid is dissolved in deionized water and ethanol solution (ethanol and deionized water, 10 mL each). While stirring, add RuCl 3 The solution was added to the suspension of lithium-rich cathode material at a dropping rate of 3mL / min, and stirred in a water bath at 80°C for 4 hours to partially evaporate the solvent. At the same time, the Ru 3+ Take Ru(OH) 3 The form precipitates on the surface of the material. After suction filtration, the suspension was vacuum-dried at 100°C for 12 hours, and then heat-treated in a tube furnace at 450°C for 3 hours, and then cooled with the furnace to obtain RuO. 2 Modified modified lithium-rich cathode material.

Embodiment 2

[0030] Weigh the composition as 0.7Li 2 MnO 3 ·0.3LiFeO 2 Add 5.000 g of lithium-rich positive electrode material to a mixed solution of deionized water and ethanol (ethanol and deionized water, 100 mL each), and ultrasonically disperse for 0.5 h. 0.1953g RuCl 3 ·XH 2 O (with RuO 2 It is dissolved in deionized water and ethanol solution (ethanol and deionized water, 10 mL each) relative to the added amount of the lithium-rich positive electrode material. While stirring, add RuCl 3 The solution was added to the suspension of lithium-rich cathode material at a dropping rate of 3mL / min, and stirred in a water bath at 80°C for 4 hours to partially evaporate the solvent. At the same time, the Ru 3+ Take Ru(OH) 3 The form precipitates on the surface of the material. After suction filtration, the suspension was vacuum-dried at 100°C for 12 hours, and then heat-treated in a tube furnace at 450°C for 3 hours, and then cooled with the furnace to obtain RuO. 2 Modified modified lithium-ric...

Embodiment 3

[0032] Weigh the composition as 0.7Li 2 MnO 3 ·0.3LiFeO 2 Add 5.000 g of lithium-rich positive electrode material to a mixed solution of deionized water and ethanol (ethanol and deionized water, 100 mL each), and ultrasonically disperse for 0.5 h. 0.3905g RuCl 3 ·XH 2 O (with RuO 2 It is dissolved in deionized water and ethanol solution (ethanol and deionized water, 10 mL each) relative to the added amount of the lithium-rich positive electrode material. While stirring, add RuCl 3 The solution was added to the suspension of lithium-rich cathode material at a dropping rate of 3mL / min, and stirred in a water bath at 80°C for 4 hours to partially evaporate the solvent. At the same time, the Ru 3+ Take Ru(OH) 3 The form precipitates on the surface of the material. After suction filtration, the suspension was vacuum-dried at 100°C for 12 hours, and then heat-treated in a tube furnace at 450°C for 3 hours, and then cooled with the furnace to obtain RuO. 2 Modified modified lithium-ric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com