Ultra high speed laser driver circuit with bandwidth compensation and driver chip

A laser driver and ultra-high-speed technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of increasing chip cost, occupying a large chip area, complex structure, etc., to eliminate the influence of parasitic capacitance and expand the bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention will be further described.

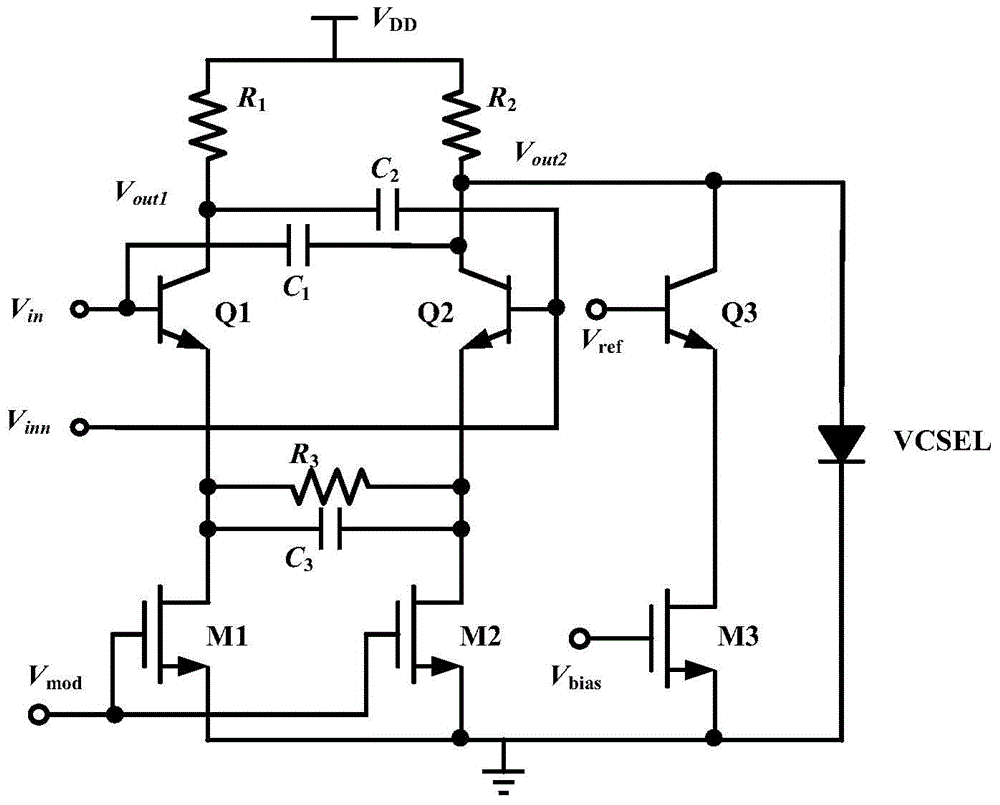

[0023] like figure 1 As shown, in the ultra-high-speed laser driver circuit with bandwidth compensation in this embodiment, the connection mode of each component is as follows:

[0024] The base of the NPN bipolar transistor Q1 is connected to the input voltage V in and capacitance C 1 The first terminal of the transistor Q1 is connected to the collector of the resistor R 1 The first terminal and the capacitor C 2 The first end of the transistor Q1, the emitter of the transistor Q1 is connected to the drain of the MOS transistor M1 on the one hand, and the resistor R is connected to the other. 3 The first terminal and the capacitor C 3 the first end of

[0025] The base of the NPN bipolar transistor Q2 is connected to the input voltage V inn and capacitance C 2The second terminal of the transistor Q2 is connected to the collector of the resistor R 2 The first terminal of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com