Aromatic hydrocarbon alkylation catalyst and application thereof

A kind of aromatic hydrocarbon alkylation and catalyst technology, applied in chemical engineering and green chemistry field, can solve problems such as short active life, achieve the effect of prolonging life, improving stability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

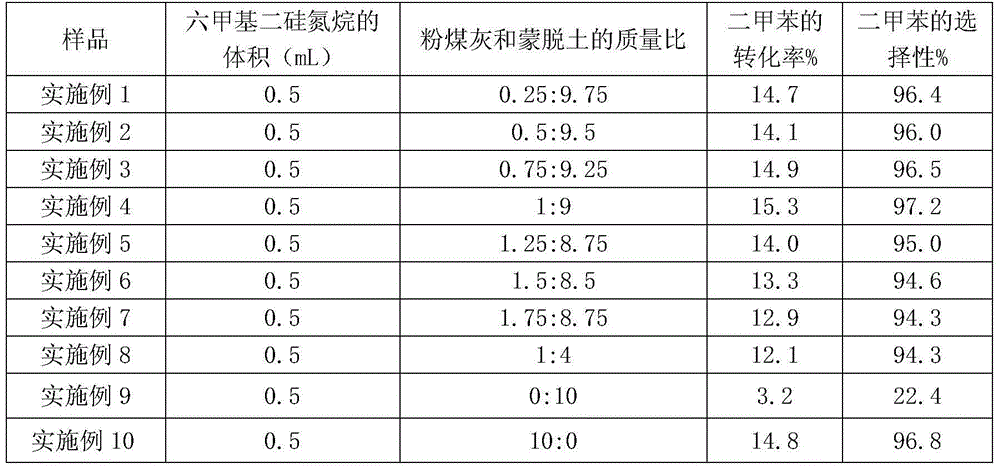

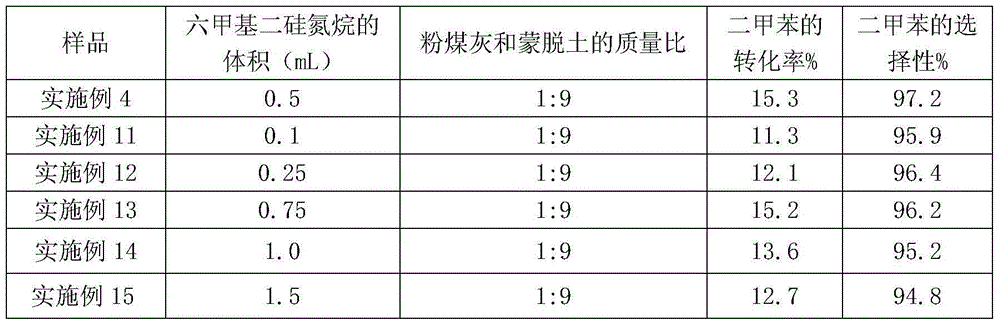

[0019] Step 1: After mixing fly ash and montmorillonite at a mass ratio of 0.25:9.75, take 10 g of the mixture and add it to 1000 ml of 4.5 mol / L sulfuric acid solution, and place it for 6 hours for acidification; The sulfuric acid was evaporated to dryness at ℃;

[0020] Step 2: Take out the dried product of step 1, add 0.5ml hexamethyldisilazane, and add a certain amount of adhesive alumina, the mass ratio of alumina to dried product is 1:0.5, stir well, Finally, the mixture is calcined in a muffle furnace at 300° C. for 8 hours;

[0021] Step 3: The substance obtained in Step 2 is washed three times with distilled water, deionized water, and analytically pure anhydrous ethanol, and the washed product is dried under 60°C vacuum to obtain an aromatic hydrocarbon alkylation catalyst.

[0022] The performance of the catalyst was evaluated in a miniature continuous flow fixed bed reactor under normal pressure. The loading amount of the catalyst was 5mL, and the temperature cont...

Embodiment 2

[0025] The difference between this example and Example 1 is that the ratio of fly ash to montmorillonite is 0.5:9.5, and the results of measured p-xylene conversion and selectivity are shown in Table 1.

Embodiment 3

[0027] The difference between this example and Example 1 is that the ratio of fly ash to montmorillonite is 0.75:9.25, and the results of measured p-xylene conversion and selectivity are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com