Energy-saving, high-efficiency, closed pressurized oil supply profile extrusion machine

A technology of extruder and pressurized oil cylinder, applied in the direction of press, oil supply tank device, mechanical equipment, etc., can solve the problem of large working stroke, large oil consumption, and affecting the service life of hydraulic oil and other problems to achieve the effect of reducing no-load travel, improving productivity and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

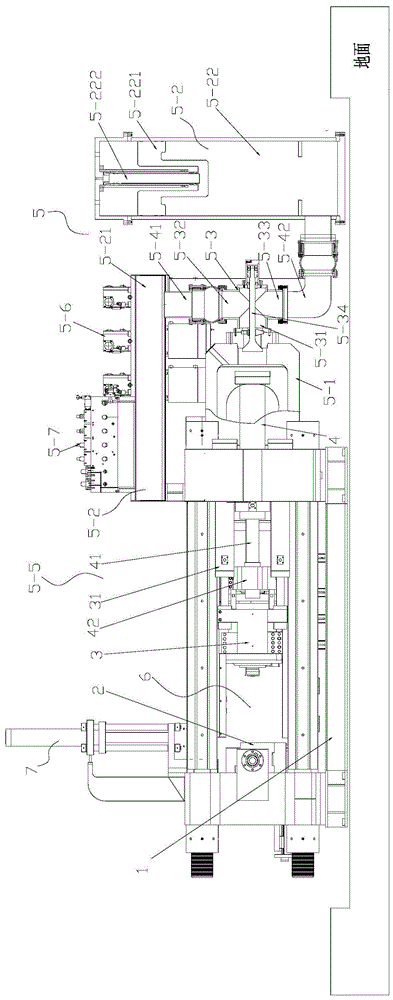

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] refer to figure 1 The shown energy-saving, high-efficiency, closed pressurized oil supply profile extruder includes a base 1, a mold 2, a spindle holder 3, an auxiliary cylinder 4, a shearing device 7 and an oil supply system 5, and the mold 2 , the ingot cylinder 3 and the auxiliary cylinder 4 are sequentially installed on the base 1; the oil supply system 5 includes an auxiliary cylinder, a main cylinder 5-1 and an oil storage tank 5-2, and the ingot cylinder 3 is in the extrusion The top position of the rod 41, the extruding rod 41 pushes the material rod in the extrusion chamber of the ingot holder 3 to produce an extrusion function, and a feeding space 6 is formed between the ingot holder 3 and the mold 2 when the ingot holder 3 is displaced; The oil storage tank 5-2 is divided into two sealed oil return oil tanks 5-21 and a pressurized oil cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com