Bidirectional extrusion mould and extrusion moulding method for double-layer metal plate and strip or sectional material

A metal strip, bidirectional extrusion technology, applied to metal extrusion dies and other directions, can solve the problems of increasing the machining and assembly of metal blanks, cracking of double-layer metal clad plates, and poor control of heating temperature, and achieves easy large-scale production. The effect of large-scale industrial production, reduction of machining and assembly links, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

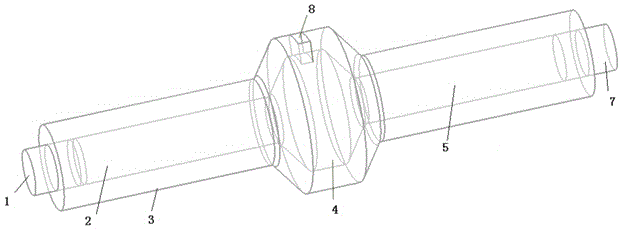

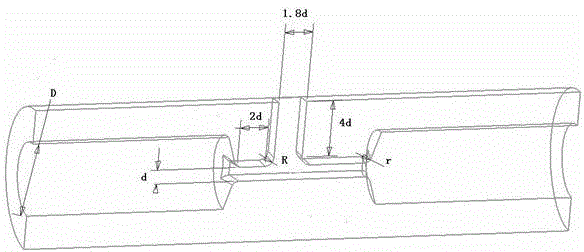

[0025] see figure 1 , a two-way extrusion die for double-layer metal strips or profiles, including a die body 3, the shape of the die body 3 can be a round shaft, a square shaft, a stepped shaft, etc., and the die body 3 of this embodiment is a stepped round shaft , the diameter of the cylinders at both ends is smaller than the diameter of the middle, and the cylinders at both ends and the middle are connected and transitioned by a circular platform; the cylinder at the left end of the mold body 3 has a first blank cavity 2, and the cylinder at the right end of the mold body 3 has a second blank cavity. The shape of the blank cavity 5, the first blank cavity 2 and the second blank cavity 5 can be a circular shaft shape, a square shaft shape, a stepped shaft shape, etc. The first blank cavity 2 and the second blank cavity 5 of this embodiment are both circular Axial shape; the middle part of the mold body 3 has a composite cavity 4, and the left and right ends of the composite ...

Embodiment 2

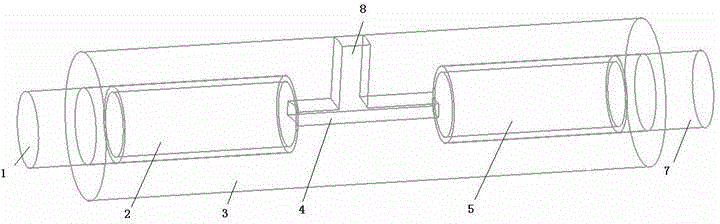

[0029] see figure 2 , a double-layer metal strip or profile bidirectional extrusion die, comprising a die body 3, the shape of the die body 3 is cylindrical, the left end of the die body 3 has a first blank cavity 2, and the right end of the die body 3 has a second The blank cavity 5, the first blank cavity 2 and the second blank cavity 5 are cylindrical; the middle part of the mold body 3 has a composite cavity 4 extending along the axial direction of the mold body 3, and the left and right sides of the composite cavity 4 The ends communicate with the first blank cavity 2 and the second blank cavity 5 respectively; the middle part of the mold body 3 has a molding cavity 8 extending along the diameter direction of the mold body 3, and one end of the molding cavity 8 communicates with the composite cavity 4, forming a T-shaped Cavity, the other end of the molding cavity 8 extends to the outer wall of the mold body 3 and forms a discharge port, and the cross-sectional shape and...

Embodiment 3

[0033] A method for forming a double-layer metal strip or profile, comprising the steps of:

[0034] 1) Clean the surface of two different metal blanks. The surface cleaning is mainly to remove the grease and scale on the metal surface, and then put the two metal blanks into the heating furnace for heating. After heating to a suitable temperature, the two The metal blanks are put into the first blank cavity 2 and the second blank cavity 5 respectively; the two different metals in this embodiment are magnesium alloy and aluminum alloy respectively, wherein the magnesium alloy is heated to 300°C, and the aluminum alloy is heated to 350°C;

[0035] 2) Control the movement of the first extruding rod 1 and the second extruding rod 7 through the telescopic device, the first extruding rod 1 and the second extruding rod 7 push two different metal blanks into the compound cavity 4, and the Under the action, the two metal blanks are composited, and the composite double-layer metal blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com