A method for preparing high niobium titanium aluminum alloy material by two-step pressure infiltration

A titanium-aluminum alloy, infiltration technology, applied in the field of intermetallic compound material preparation, to achieve the effect of excellent material mechanical properties, improve high impurity content, and reduce material production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

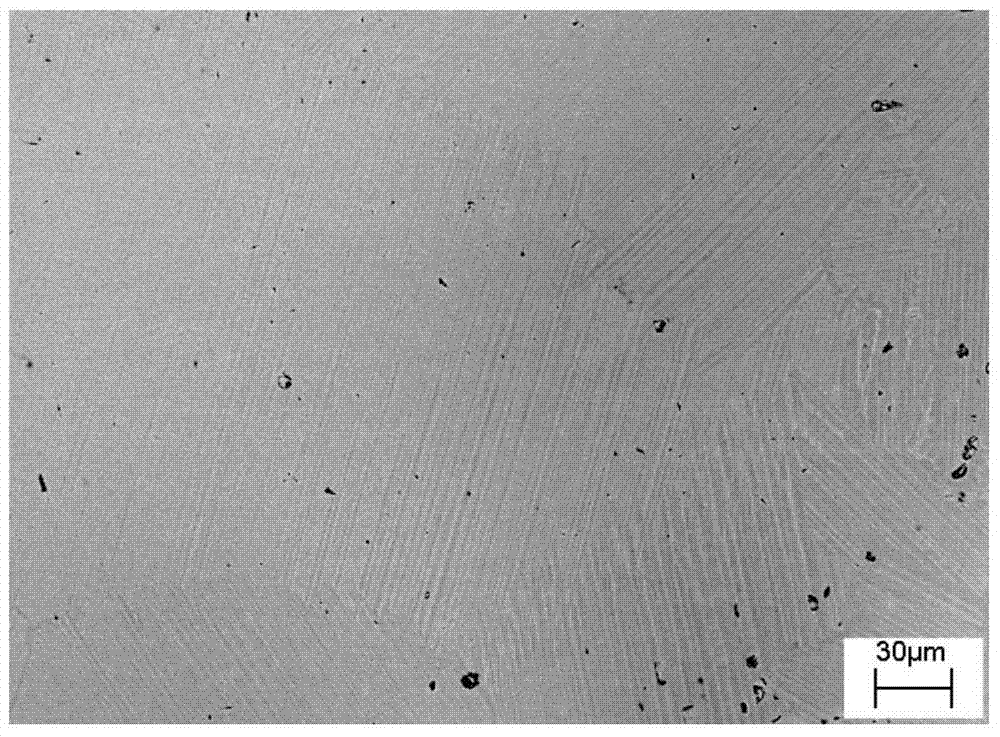

Embodiment 4

[0025] -200 mesh Ti powder, -325 mesh Nb element powder and high-purity Al plate are used as raw materials, and the ratio is carried out according to the nominal composition Ti-45Al-8.5Nb. After mechanically mixing the Ti and Nb element powders uniformly, they were put into a Φ30 graphite mold, vibrated and pressed to obtain a green compact with a density of 68%. After polishing the surface of the wire-cut Al plate, place it on the powder compact in the mold, and then put the mold as a whole into a high-pressure infiltration furnace. The infiltration process is carried out under the protection of high-purity Ar gas, and the temperature is rapidly raised to 750°C at 10°C / min, and the heat preservation time is 60min. After 20min of heat preservation, an axial pressure of 20MPa is applied; °C / min. Slowly raise the temperature to 850 °C, keep the temperature for 120 min, and then continue to pressurize and cool to room temperature with the furnace to obtain a high-niobium titanium...

Embodiment 5

[0027]-500 mesh Ti, Nb element powder and high-purity Al plate are used as raw materials, and the ratio is carried out according to the nominal composition Ti-45Al-5Nb. After the Ti and Nb element powders were mechanically mixed, they were put into a Φ30 graphite mold and vibrated to obtain a powder green body with a density of 56%. After polishing the surface of the wire-cut Al plate, place it on the mixed powder in the mold, and then put the mold as a whole into a high-pressure infiltration furnace. Infiltration process in the vacuum degree ≤ 10 -1 Under the vacuum condition of Pa, the temperature is raised rapidly to 700°C at 5°C / min, and the heat preservation time is 40min, and the axial pressure of 30MPa is applied after 10min of heat preservation; the axial pressure is increased to 30MPa, and the temperature is slowly raised at 6°C / min To 1000 ℃, keep warm for 60 minutes, then continue to pressurize and cool to room temperature with the furnace, and then obtain high-nio...

Embodiment 6

[0029] -325 mesh Ti powder, -500 mesh Nb element powder and high-purity Al plate are used as raw materials, and the ratio is carried out according to the nominal composition Ti-45Al-10Nb. After the Ti and Nb elemental powders are mechanically mixed, they are put into a Φ30 graphite mold, vibrated and pressed to obtain a green compact with a density of 60%. The wire-cut Al plate is placed on the powder body in the mold, and then the whole mold is placed in a high-pressure infiltration furnace. The infiltration process is carried out under the protection of high-purity Ar gas, and the temperature is rapidly raised to 800°C at 7°C / min, and the heat preservation time is 120min. After 30min of heat preservation, an axial pressure of 10MPa is applied; °C / min. Slowly raise the temperature to 950 °C, hold the temperature for 80 minutes, and then continue to pressurize and cool to room temperature with the furnace, and then the high-niobium titanium-aluminum alloy infiltration green bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com