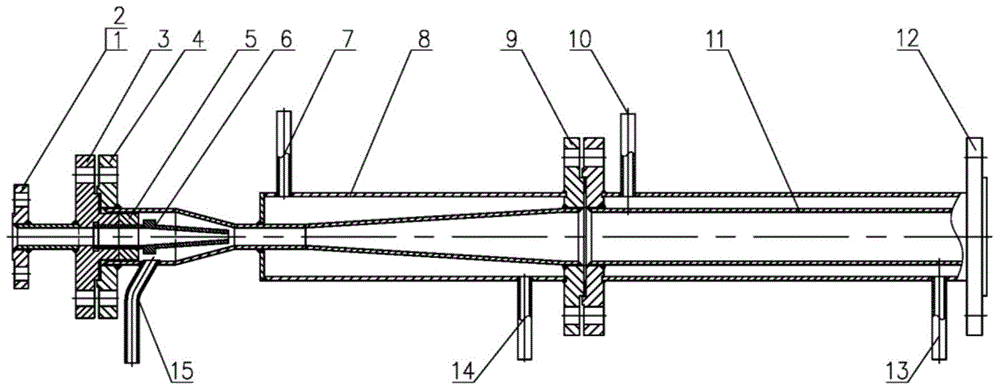

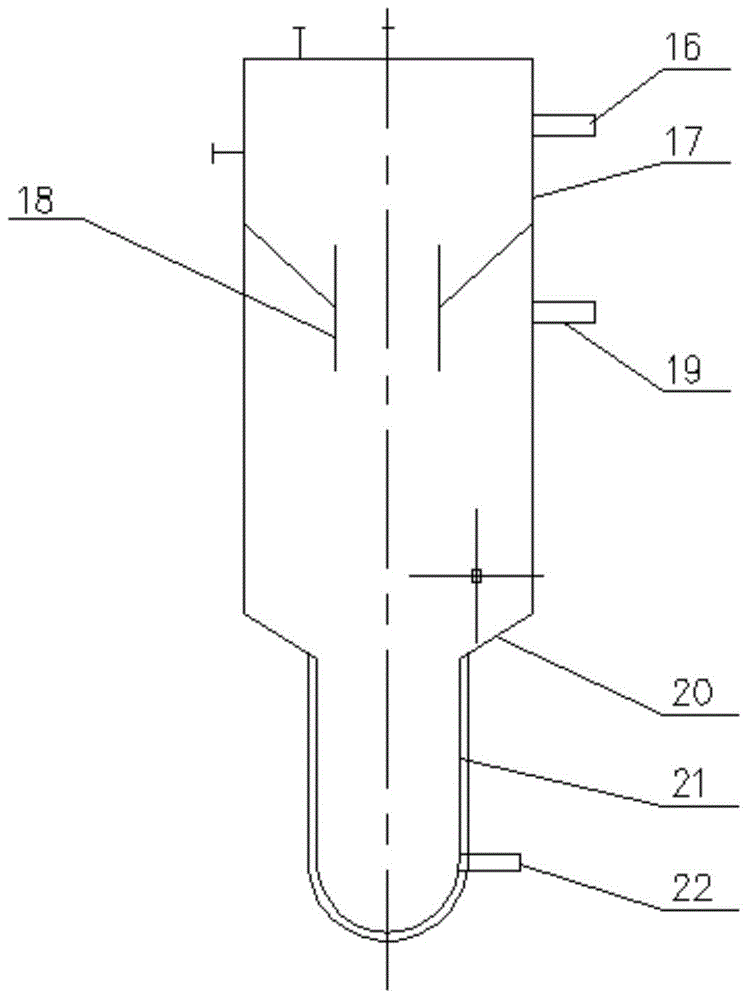

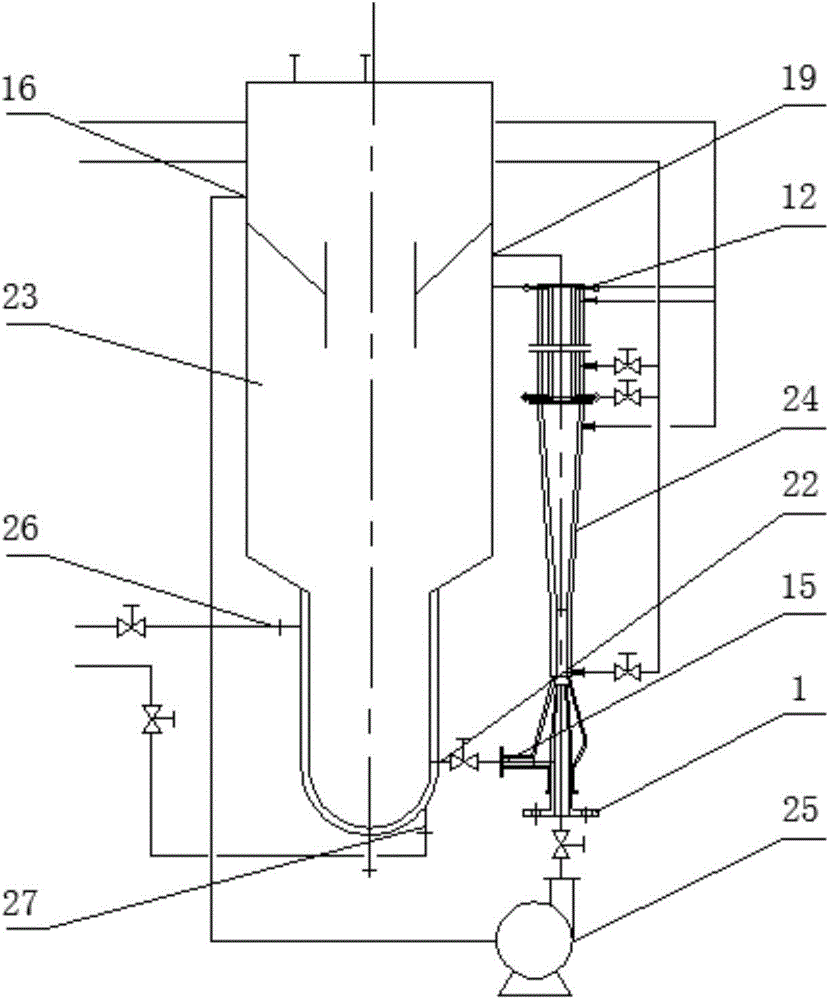

Device and treating method for purification and dearsenification of industrial yellow phosphorus

A yellow phosphorus and arsenic removal technology, which is applied in chemical instruments and methods, phosphorus compounds, chemical industry, etc. Parts and other issues, to achieve the effect of easy automation, commercialization requirements, continuous and uninterrupted operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: put yellow phosphorus, hydrogen peroxide, and catalyst into the agitator according to a certain ratio to carry out pre-reaction mixing for arsenic removal, open the stop valve, add the mixed solution (the arsenic content is about 400ppm) into the cyclone phase separator 23, and let it rest After a period of time, yellow phosphorus and hydrogen peroxide were initially separated. Open the valve between the binary jet reactor 24 and the circulating pump 25, the valve between the yellow phosphorus suction pipe 15 and the yellow phosphorus outlet connecting pipe 22, and the mixed liquid outlet of the binary jet reactor 24 and the tangential inlet of the cyclone phase separator 23 between valves. Start the circulating pump 25, and the hydrogen peroxide in the cyclone phase separator 23 is delivered to the hydrogen peroxide connecting pipe 2 of the binary jet reactor 24 by the pressure of the pump, and is injected at a high speed through the nozzle 6 to form a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com