A kind of columnar coconut shell activated carbon and preparation method thereof

A coconut shell activated carbon and columnar technology, which is applied in the field of preparation of activated carbon materials, can solve the problem of low mesoporosity and achieve the effect of high strength and high mesoporosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

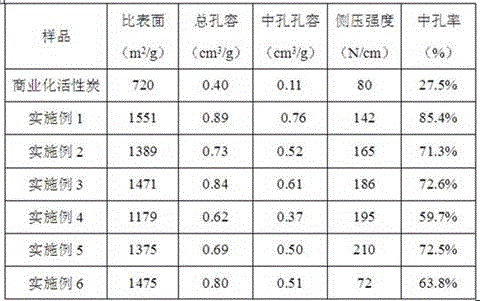

Embodiment 1

[0022] Soak the clean coconut shell in 5 wt% sulfuric acid solution for 15 h, wash and dry; then crush the coconut shell with a pulverizer and pass through a 150-mesh sieve; take 50 g of coconut shell powder for later use, and select the organic binder from field Cyanine powder, the addition amount is 4 g, add phosphoric acid, the mass ratio of phosphoric acid and coconut shell powder is selected as 1.5:1, the water amount is controlled at 15 g, and soaked at 40°C for 2 hours; after mixing evenly, start kneading, set the time for 30 minutes, and then set Molding was carried out in the extruder, and then the columnar material was solidified and shaped in an oven at 150 °C for 1 hour, and then the material was put into an atmosphere furnace for carbonization and activation. Ar gas atmosphere was used, the flow rate was controlled at 300 mL / min, and the final temperature was set at 300 mL / min. Set at 500°C and activate at constant temperature for 1h. After rinsing the activated c...

Embodiment 2

[0024] After soaking the clean coconut shell in 10 wt% hydrochloric acid solution for 10 h, wash and dry it; then crush it with a pulverizer and pass through a 150-mesh sieve; take 50 g for later use, the organic binder is polyvinyl alcohol, and the addition amount is 4 g, add phosphoric acid, the mass ratio of phosphoric acid to coconut shell powder is 1:1, the water volume is controlled to 15 g, soak at 30°C for 3 hours, after mixing evenly, start kneading, set the time for 30 minutes, and then place it in the extruder After molding, the columnar material was solidified and shaped in an oven at 130°C for 3 hours, and then the material was put into an atmosphere furnace for carbonization and activation. Ar gas atmosphere was used, the flow rate was controlled at 400 mL / min, and the final temperature was set at 700°C. Activate for 1h. After rinsing the activated columnar carbon, the pH value is 6~7, and then drying to obtain the sample. The parameters are shown in the table be...

Embodiment 3

[0026] After soaking the clean coconut shell in 1wt% strong acid solution for 20h, wash and dry; then pulverize with a pulverizer, and pass through a 150-mesh sieve; take 50 g for later use, and the organic binder is selected from kale powder and polyvinyl alcohol, The mixing mass ratio is 1:1, and the addition amount is 4g; then add phosphoric acid, the mass ratio of phosphoric acid and coconut shell is selected as 1:1, the water volume is controlled at 15 g, and soaked at 50°C for 1 hour; after mixing evenly, start kneading, time Set it up for 30 minutes, then place it in the extruder for molding, then the columnar material is cured and shaped in an oven at 50°C for 3 hours, and then put the material into the atmosphere furnace for carbonization activation, using Ar gas atmosphere, and the flow rate is controlled at 300 mL / min , the final temperature was set at 1100°C, and the constant temperature activation was performed for 1 hour. After rinsing the activated columnar carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com