Method for enhancing fluorescence of upconversion material

A technology for fluorescence enhancement and conversion materials, which is applied in nanotechnology, luminescent materials, chemical instruments and methods for materials and surface science, and can solve the problems of low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of Upconverting Nanoparticles

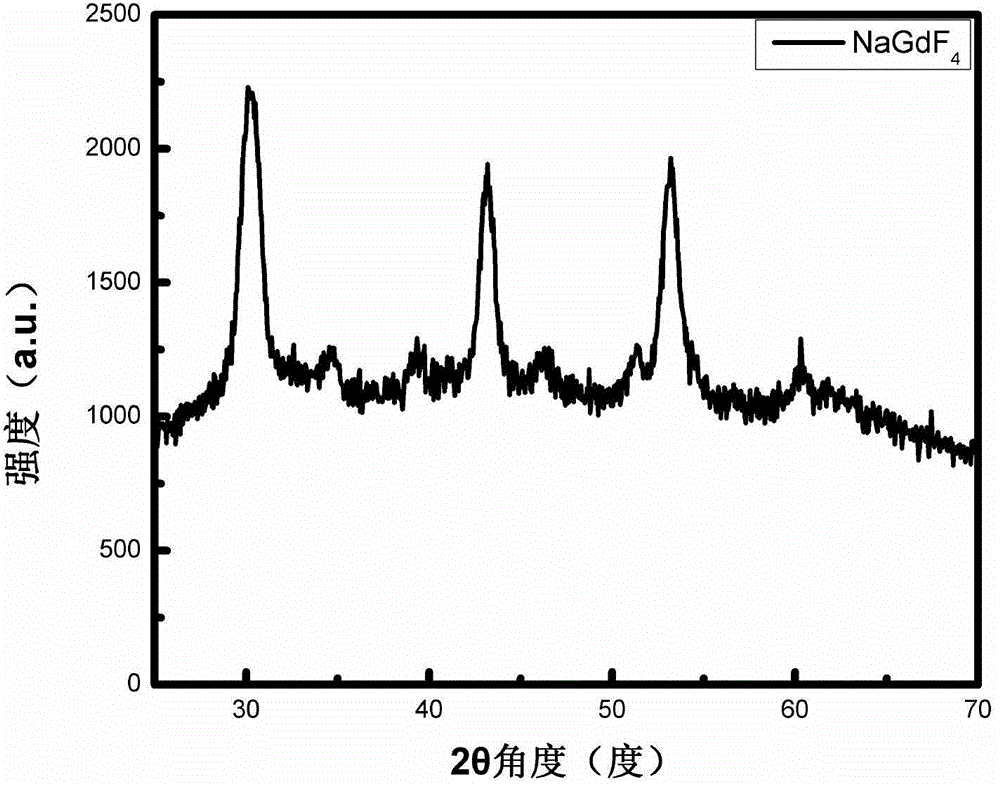

[0036] 0.78 mmol GdCl 3 ·6H 2 O, 0.2 mmol YbCl 3 ·6H 2 O, 0.02 mmol ErCl 3 ·6H 2 O is placed in a reaction vessel, and the high boiling point organic solvent oleic acid and 1-octadecene are mixed in a volume ratio of 2:5 as the reaction solvent. After fully stirring, the temperature is raised to 140°C to form a homogeneous phase and then cooled to room temperature (25°C). , slowly added 5 mL containing NaOH (2.5 mmol) and NH 4 The methanol solution of F (4 mmoles) was fully stirred and heated to 70° C. to evaporate the methanol, and after the methanol was evaporated, the temperature was raised to 300° C. and reacted for 1.5 hours to obtain up-conversion nanoparticles; figure 1 It is the powder X-ray diffraction spectrum of the up-conversion nanoparticles. It can be seen from the figure that it is consistent with the standard card, indicating that β-NaGdF was successfully prepared. 4 .

[0037] 2. Homogeneous coating...

Embodiment 2

[0045] 1. Preparation of Upconverting Nanoparticles

[0046] 0.78 mmol YCl 3 ·6H 2 O, 0.2 mmol YbCl 3 ·6H 2 O, 0.02 mmol ErCl 3 ·6H 2 O is placed in a reaction vessel, and the high boiling point organic solvent oleic acid and 1-octadecene are mixed at a volume ratio of 2:5 as the reaction solvent. After stirring thoroughly, the temperature is raised to 160°C, and a homogeneous phase is formed, then cooled to room temperature (25°C) , slowly added 5 mL containing NaOH (2.5 mmol) and NH 4 The methanol solution of F (4 mmoles) was fully stirred and heated to 90° C. to evaporate the methanol, and after the methanol was evaporated, the temperature was raised to 290° C. and reacted for 3 hours to obtain up-conversion nanoparticles;

[0047] 2. Homogeneous coating of nanoparticles

[0048] 0.122 g of YCl 3 ·6H 2 O was placed in a reaction solvent mixed with oleic acid and 1-octadecene at a volume ratio of 2:5, stirred thoroughly and then heated to 160°C to dissolve, forming ...

Embodiment 3

[0054] 1. Preparation of Upconverting Nanoparticles

[0055] 0.76 mmol GdCl 3 ·6H 2 O, 0.2 mmol YbCl 3 ·6H 2 O, 0.04 mmol TmCl 3 ·6H 2 O is placed in a reaction vessel, and the high boiling point organic solvent oleic acid and 1-octadecene are mixed at a volume ratio of 2:5 as the reaction solvent. After stirring thoroughly, the temperature is raised to 150°C, and a homogeneous phase is formed, then cooled to room temperature (25°C) , slowly added 5 mL containing NaOH (2.5 mmol) and NH 4 The methanol solution of F (4 mmoles) was fully stirred and heated to 80° C. to evaporate the methanol, and after the methanol was evaporated, the temperature was raised to 320° C. and reacted for 1 hour to obtain up-conversion nanoparticles;

[0056] 2. Homogeneous coating of nanoparticles

[0057] 0.145 g of GdCl 3 ·6H 2 O was placed in a reaction solvent mixed with oleic acid and 1-octadecene at a volume ratio of 2:5, stirred thoroughly and then heated to 150°C to dissolve, forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com