A method for treating soft ground with microbial grouting drainage sand pile

A technology of soft soil foundation and drainage sand pile, which is applied in the direction of soil protection, chemical instruments and methods, fertilizer mixture, etc. It can solve the problems of sand pile drainage performance decline, uneconomical, large amount of cement slurry, etc., and achieve deformation resistance The effect of improving bearing capacity, vertical compressive stiffness and strength, and pile body stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

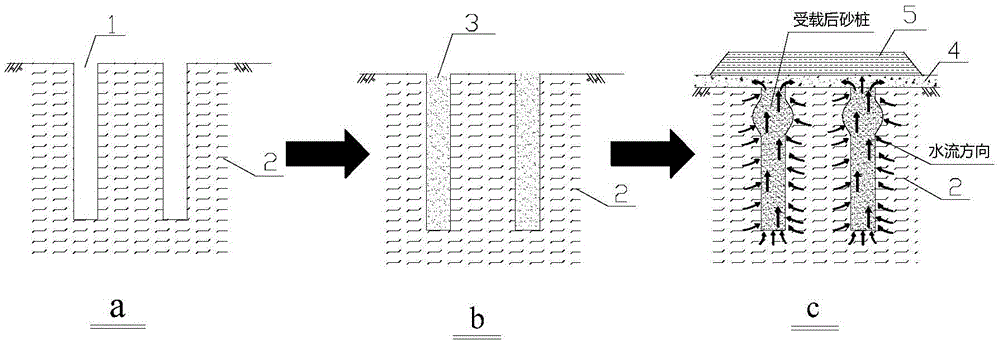

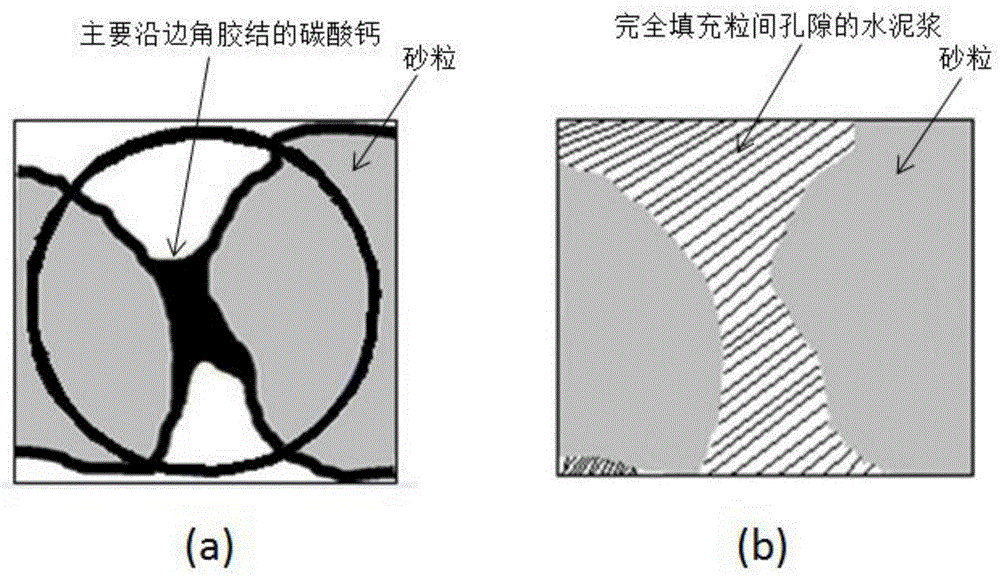

[0034] In this example, a method for treating soft soil foundations with microbial grouting drainage sand piles is used to treat saturated soft clay foundations (such as Figure 4 shown), the method includes the following steps:

[0035] a. In the soft foundation to be treated, use vibration or hammer sinking method to sink into the steel pipe 11 to squeeze the soil to form the pile hole 1, and pre-embed the grouting pipe 6 in the pile hole 1, and the grout outlet is located at the bottom of the pile hole, and Pour sand into the pile hole 1 on the periphery of the grouting pipe 6 and pull out the steel pipe 11 to form a sand pile;

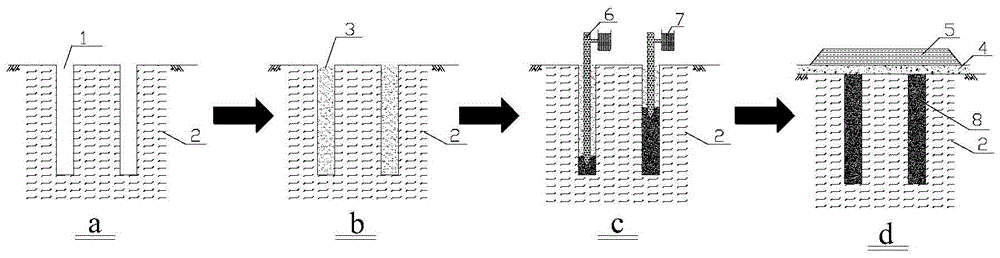

[0036] b. the pre-prepared urease-producing bacteria bacterium liquid 9 (bacterial liquid concentration OD 600 =1.5 diluted 10 times) and nutrient salt solution 10 (solution consists of the calcium chloride of 0.2mol / L, the urea of 0.40mol / L, the sodium acetate of 0.15mol / L, the ammonium chloride of 0.01mol / L and the ammonium chloride of 0.1g / L ...

Embodiment 2

[0040] In this example, a method for treating soft soil foundations with microbial grouting drainage sand piles is used to treat saturated soft clay foundations (such as Figure 4 shown), the method includes the following steps:

[0041] a. In the soft foundation to be treated, use vibration or hammer sinking method to sink into the steel pipe 11 to squeeze the soil to form the pile hole 1, and pre-embed the grouting pipe 6 in the pile hole 1, and the grout outlet is located at the bottom of the pile hole, and Pour sand into the pile hole 1 on the periphery of the grouting pipe 6 and pull out the steel pipe 11 to form a sand pile;

[0042] b. Prepare the urease-producing bacteria bacterium liquid 9 (bacterial liquid concentration OD 600 =1.5) and nutrient salt solution 10 (solution consists of the calcium chloride of 0.25mol / L, the urea of 0.50mol / L, the sodium acetate of 0.175mol / L, the ammonium chloride of 0.0125mol / L and the yeast of 0.1g / L paste) at the construction si...

Embodiment 3

[0046] In this example, a method of microbial grouting and drainage sand piles for treating soft soil foundations is used to treat saturated silt foundations (such as Figure 5 shown), the method includes the following steps:

[0047] a. In the soft foundation to be treated, use vibration or hammer sinking method to sink into the steel pipe 11 to squeeze the soil to form the pile hole 1, pour coarse sand into the pile hole 1 and pull out the steel pipe 11 to form a sand pile, and the top surface of the pile is slightly 40cm lower than the soil surface around the pile, forming a pile top pit 12;

[0048] b. the pre-prepared urease-producing bacteria bacterium liquid 9 (bacterial liquid concentration OD 600 =1.5) and nutrient salt solution 10 (the solution consists of the calcium chloride of 0.3mol / L, the urea of 0.60mol / L, the sodium acetate of 0.2mol / L, the ammonium chloride of 0.015mol / L and the yeast of 0.1g / L paste) according to the volume ratio of 0.06:1, the mixed gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com