Rocket thrust chamber provided with acoustic cavity and applied to supersonic airliner and supply system thereof

A rocket propulsion and supply system technology, which is applied in the direction of rocket engine devices, mechanical equipment, jet propulsion devices, etc., can solve problems such as the inability to use liquid rocket engines, achieve suppression of high-frequency unstable combustion, improve working conditions, and reduce corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

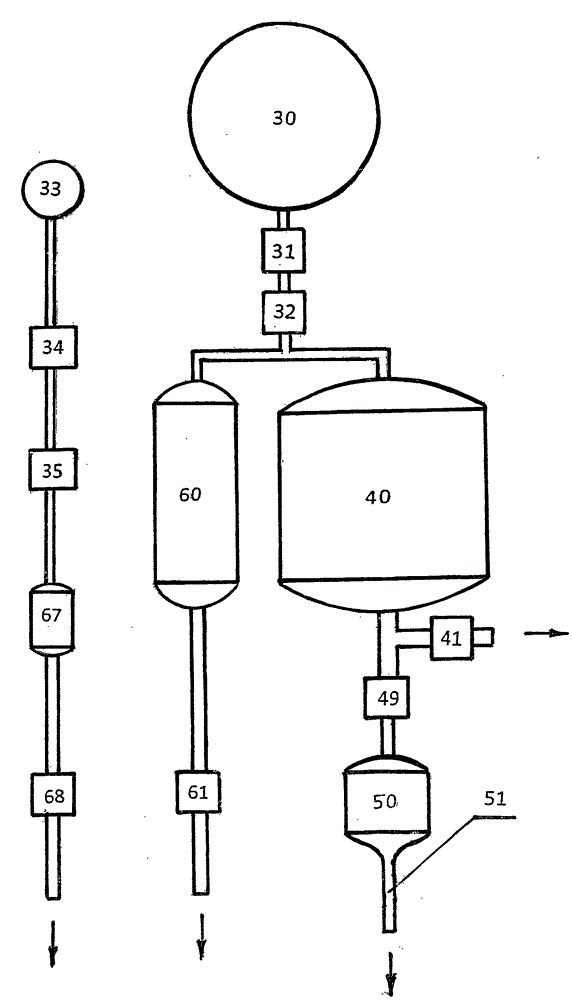

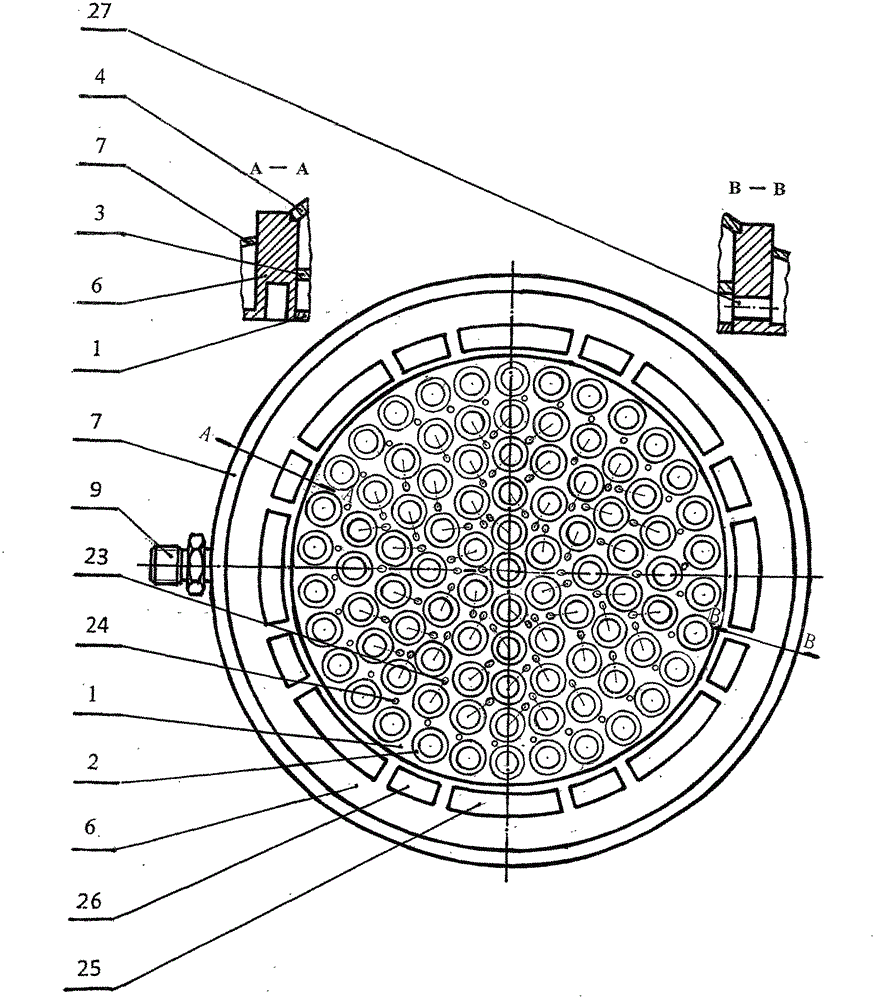

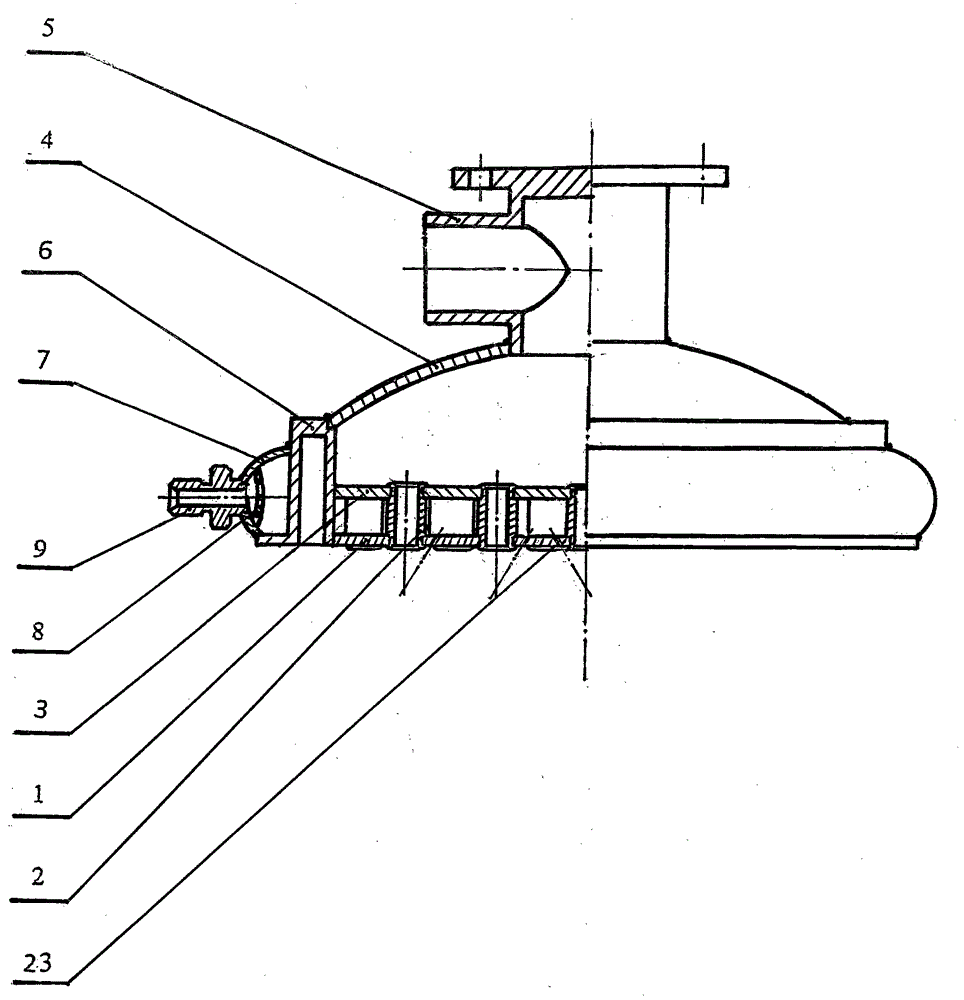

[0027] figure 1 , figure 2 , image 3 and Figure 4 It is a preferred embodiment of a rocket thrust chamber with an acoustic cavity in the present invention. Figure 5 and Figure 6 It is a preferred embodiment of the supply system matched with the thrust chamber.

[0028] Such as Figure 1 to Figure 4 As shown, a rocket thrust chamber with an acoustic cavity of the present invention is composed of a head and a body, and the head includes an inner bottom 1, an oxygen-enriched nozzle 2, a middle bottom 3, an outer bottom 4, a connecting seat 5 with an oxygen-enriched inlet pipe, Acoustic cavity 6, liquid collector ring 7, filter screen 8 and kerosene inlet nozzle 9, the body includes hydrogen peroxide inlet pipe 10, liquid collector ring 11, filter screen 12, diffuser shell 13, connecting flange 14, Nozzle extension section 15, herringbone ring 16, variable section pipe 17, convergent section casing 18, cylindrical section casing 19, liquid collector ring 20, hydrogen pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com